EXPERIMENTAL INVESTIGATION ON R134AAIRBORNE VAPOR-COMPRESSION REFRIGERATION SYSTEM

Li Yunxiang(李运祥),Pan Quan(潘泉),Liu Juan(刘娟)

(1.Collage of Automation,Northwest Polytechnical University,Xi′an,710072,P.R.China;2.College of Aerospace Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing,210016,P.R.China)

INTRODUCTION

With the rapid development of fighter planes,more and more modern avionics (electronic systems employed in aircraft)and aircraft power electronics are equipped in airframes.And effective heat removal techniques are highly required because the improvements in such electronics generally lead to substantial miniaturization.Therefore,higher heat fluxes are presented[1].The avionics and power electronics cooling systems must keep the electronic junction temperatures below predetermined limits to provide survivability under all operating conditions.As component reliability is based upon response time at a given temperature,temperature sensitive components should be maintained as cool as possible[2-5].The traditional air cycle system extracts a large amount of"bleed air"from the engine core compressor ports to cool different zones and components.However,in terms of engine fuel con-sumption,bleed air is very expensive while its cool capacity is very limited[4].The vapor-compression refrigeration system(VCRS)using evaporation and condensation are known as the best way to meet the cooling requirements in terms of compactness,weight and energy consumption.As one of the fundamental advantages of the twophase systems,the large heat transfer coefficient of film boiling in the cold plate ranges from 10 000—100 000W/(m2·°C)which is one order of magnitude larger than that of conventional liquid cooling cold plates.The larger heat transfer coefficient is translated into a smaller thermal resistance and consequently high heat flux capability[6-8].Another advantage is that the large latent heat capability of VCRS can be typically two orders of magnitude larger than the sensible heat of a liquid-phase cooling system.Therefore,VCRS requires much less coolant flow,resulting in a very compact pumping system[9].Furthermore,isothermal evaporation is another important fea-ture of two-phase cooling systems because excessive temperature non-uniformity in silicon chips reduces their reliability and thermal stresses cause functional failures.The synergic effect by high heat flux capability is ethereality.Small liquid flow requirement of VCRS can effectively address the challenging cooling demands we are facing.

As to VCRS,some researchers have already identified vapor-compression refrigeration technologies used in residential air conditioning or other refrigeration components.However,the airborne VCRS is different from the residential system because the cooling source is not environment air but antifreeze liquid.The condenser is cooled by the hot antifreeze loop with antifreeze liquid.Meanwhile,the cooling capacity served by evaporator is transferred into the components through antifreeze liquid of the cold antifreeze loop.Many researchers have also studied twophase systems as a promising solution to emerging cooling needs based on performance,mass,reliability and cost considerations.Among them are widely-used passive two-phase cooling technologies including heat pipe and loop heat pipes(LHP)[10-12].They are highly reliable and thermal conductive devices.However,the passive operation relying on capillarity can ultimately limit the improvement in heat flux,transport distance and dimension capabilities.Therefore,aiming at future fighter plane demanding,a large amount of waste heat,high heat flux and critical space,VCRS with high heat transfer rate,low energy consumption,non-limited transport distance[13-15]stands out as the cooling system in airborne environment control system.

In the present work,the operation performances of VCRS with R134aare studied experimentally.And the effects of evaporation pressure,condensing pressure,refrigerant mass flow rate and compressor rotation on compressor power consumption,refrigeration capacity and energy efficiency ratio are also investigated.

1 EXPERIMENT DESCRIPTION

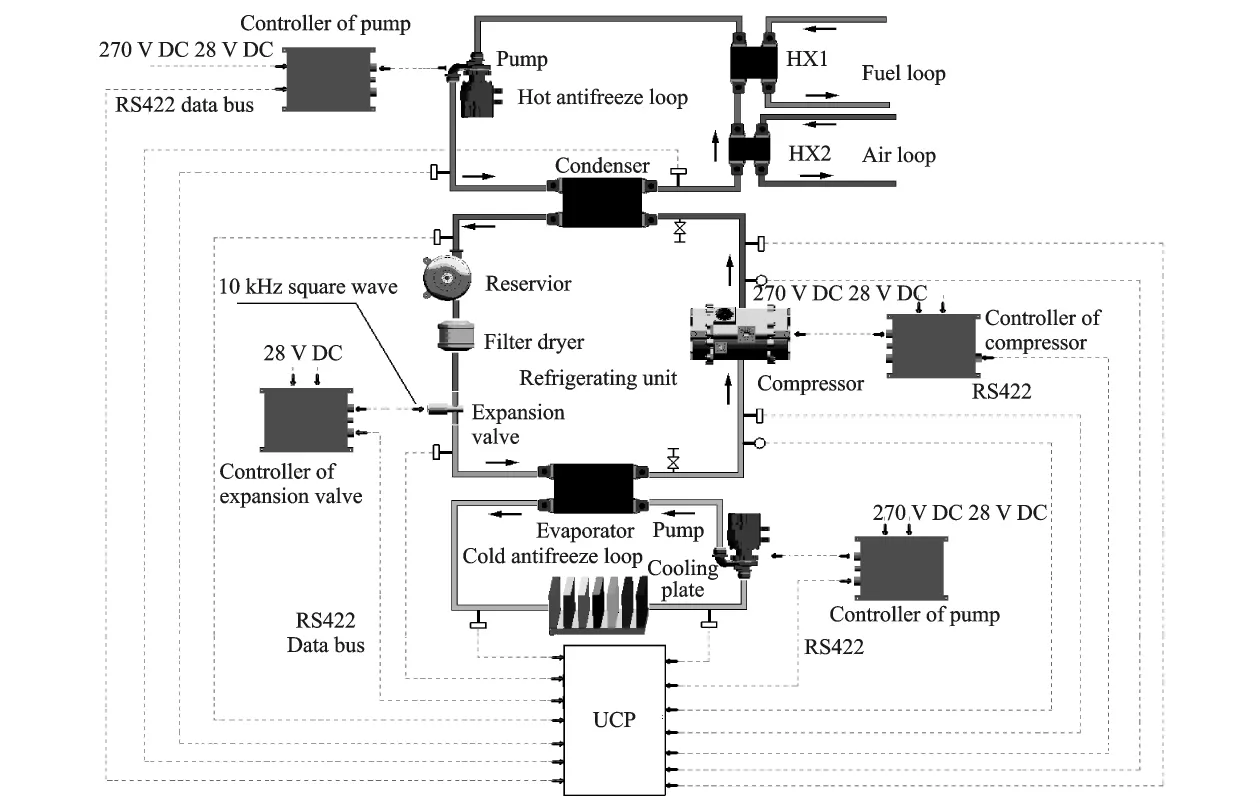

VCRS consists of hot antifreeze loop,cold antifreeze loop and refrigerating unit.The experiment principle is shown as follows.

Fig.1 Schematic diagram of VCRS

As shown in Fig.1,the refrigerating unit of the system consists of evaporator,expansion valve,condenser and the compressor as the simplest design.The hot antifreeze loop connected with the condenser is responsible for transporting the heat released by the condenser.The cold antifreeze loop joined with the evaporator is to refrigerate the equipments with cooling requirements.The hot antifreeze loop connected with the condenser includes heat exchangers and a pump.The heat exchangers realize heat transfer process by the fuel and the engine bleed air.The pump is controlled by apump controller.The cold antifreeze loop supplies chilled antifreeze liquid to the cooling plate.The cooling plate is in charge of cooling process which removes the heat released by the electronics or other equipments.In this loop,apump is employed to circulate chilled water through the evaporator and the cooling plate.

2 EXPERIMENTAL PROCEDURE

Experiments are conducted by using the experimental apparatus in Fig.2.The experimental setup is located in Nanjing,China.Fig.2 (a)is an overview of the experimental system,including the refrigerant unit,the hot antifreeze loop and the cold antifreeze loop.In each unit/loop,some multi-transducer and valves are deployed.The valves adjust the opening according to the temperature or pressure signal,so the temperature or pressure can be controlled in some level through these closed control group.Fig.2 (b)gives some details about the components used in the experiment.

In the experiment,the experimental performance evaluation of VCRS is carried out based on the data derived from tests.There are multitransducers deployed in the bench system to obtain different parameters during the experiment.For example,the temperature transducers are located in the inlet and the outlet of the antifreeze liquid of the cold antifreeze loop to obtain the inlet/outlet temperature;the galvanometer and the voltmeter are equipped to measure the current and voltage of the compressor.Through all the parameters obtained from the experiment test,we can analyze the impact of these parameters on the system refrigeration capacity,the compressor consumption and the energy,efficiency,and ratio(EER).EER is a measure of the system efficiency.Since the pump of the system always works on the same condition and its consumption is constant,EER is the ratio of the system refrigeration capacity to the compressor consumption,neglecting the impact of the pump.

Fig.2 Experimental apparatus

In the application of the airborne VCRS,the condenser pressure,the refrigerant mass flow rate and the compressor rotation are the may regulating parameters,so the experiments are conducted under the following operating conditions:

(1)Operating condition 1

Compressor speed,evaporation pressure,refrigerant mass flow rate,antifreeze liquid flow rate of hot antifreeze loop,lab environment temperature and pressure are constant.Change the condensing pressure to obtain its relations with the parameters of compressor power consumption,the refrigeration capacity and EER.

(2)Operating condition 2

Compressor speed,evaporation pressure,anti-freeze liquid flow rate of hot antifreeze loop,antifreeze liquid flow rate of cold antifreeze loop,lab environment temperature and pressure are constant.Change the condensing pressure to obtain the relations of the compressor power consumption,the refrigeration capacity,the refrigerant mass flow rate and EER with the condensing pressure.

(3)Operating condition 3

Condensing pressure,antifreeze liquid flow rate of hot antifreeze loop,antifreeze liquid flow rate of cold antifreeze loop,lab environment temperature and pressure are constant.Refrigeration capacity is around 41kW.The compressor speed input is various.Obtain the relations between the condensing pressure and the performance parameters,including the evaporation pressure,the refrigerant mass flow rate,the refrigerant mass flow rate and EER.

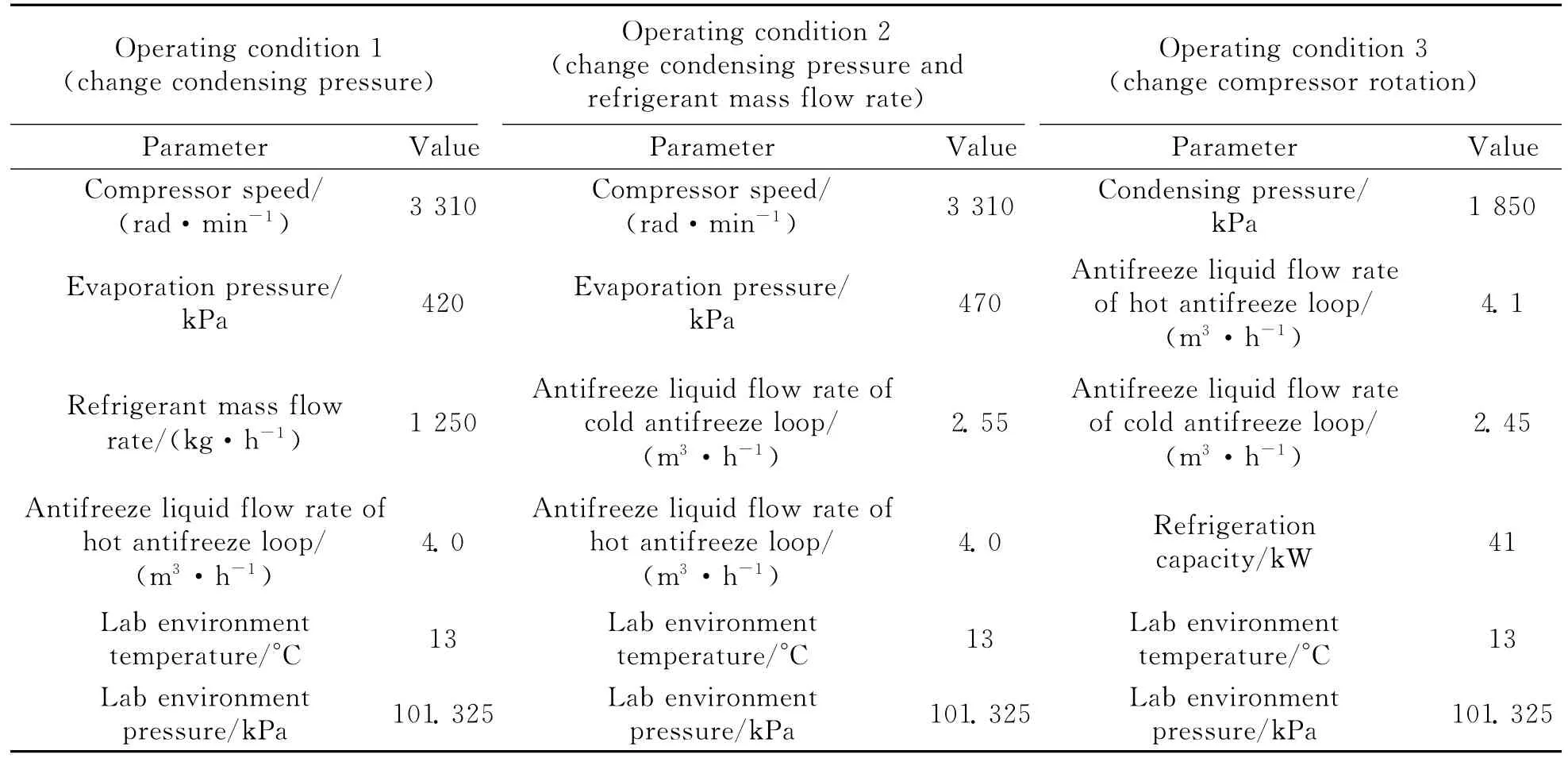

The details of the three operating conditions are shown in Table 1.

Table 1 Operatingcondition information

3 RESULT AND DISCUSSION

In this experiment,some parameters can be tested directly and some indices should be calculated.The compressor power consumption is obtained by voltage and current.Refrigeration capacity is obtained as the products of mass flow rate of the refrigerant,specific heat and temperature difference across respective component.EER is estimated by measuring the rotio of the system refrigeration capacity to compressor power consumption.Calculations are also conducted based on the VCRS measurements by evaluating the performance indices under different operating conditions.

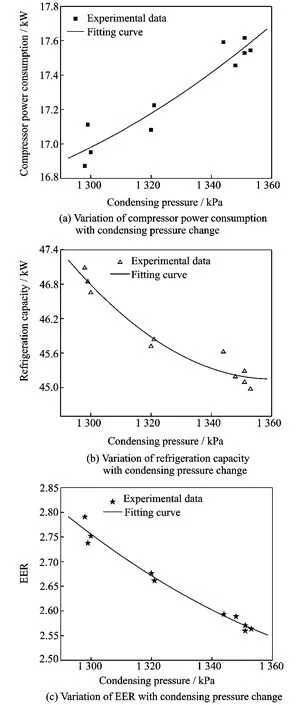

Fig.3indicates how compressor power consumption,refrigeration capacity and EER vary with the change of condensing pressure of VRCS under operating condition 1.

From Fig.3,it can be observed that,the compressor power consumption increase with the growth of the condensing pressure,the refrigeration capacity and EER of VCRS decrease with the growth of the condensing pressure.This fact suggests that when the compressor inlet pressure is constant,the compression power consumption gains with the increase of the condensing pressure.The refrigeration capacity of the unit volume decreases,while the refrigerant mass flow rate of the system is invariant.And these cause the refrigeration capacity descends and the compressor power consumption increases,which results in the decline of EER.

Fig.3 Thermodynamic evolution of compressor power consumption,refrigeration capacity and EER depending on condensing pressure under condition 1

The relations between the condensing pressure,and the compressor power consumption,re-frigeration capacity,refrigerant mass flow rate,EER ratio of VCRS,respectively,under operating condition 2,are shown in Fig.4.

Fig.4 Thermodynamic evolution of compressor power consumption,refrigeration capacity,refrigerant mass flow rate and EER depending on condensing pressure under condition 2

As shown in Fig.4,increasing condensing pressure under operating condition 2leads to the increase of the refrigerant mass flow rate of VCRS from 1 325to 1 385kg/h,the decrease of EER,and the increase of the compressor power consumption and refrigeration capacity.It is further observed that the refrigerant mass flow rate gains are larger than that of the refrigeration capacity.This fact suggests that the refrigeration capacity of unit volume decreases,and the compressor power consumption gains are larger than that of the refrigeration capacity,which leads to the decrease of EER of the system.Fig.4discerns the variation of EER with the change of condenser pressure.

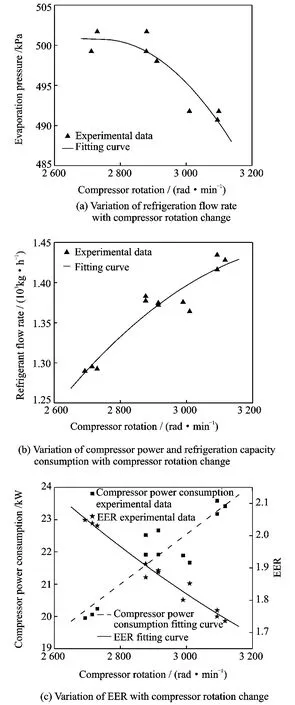

Fig.5illustrates the effect of compressor rotation on refrigerating compressor power consumption,refrigeration capacity,refrigerant mass flow rate and EER under operating condi-tion 3.

Fig.5 Thermodynamic evolution of compressor power consumption,refrigeration capacity,refrigerant mass flow rate and EER depending on compressor rotation under condition 3

From Fig.5,it is noted that the evaporation pressure gains with the decrease of the compressor rotation when the refrigeration capacity is constant.It is also observed that the refrigerant mass flow rate varies between 1 290and 1 420 kg/h with the variation of the compressor rotation.Obviously,when the refrigeration capacity is constant,with the increase of the compressor,the evaporation pressure decreases,and the refrigerant mass flow rate increases,leading to the decrease of refrigeration capacity of unit volume,so EER decreases with the increase of the compressor rotation.

4 CONCLUSIONS

The factors influencing the VCRS performance,such as evaporation pressure,condensing pressure,refrigerant mass flow rate and compressor rotation,are investigated experimentally.It is proved through the experimental tests that VCRS is feasible to be applied in modern airborne with high electronic cooling requirements.Main conclusions are as follows:

(1)When the compressor speed,evaporation pressure,refrigerant mass flow rate,antifreeze liquid flow rate of the hot antifreeze loop are constant,only changing the condensing pressure and appropriately reducing the condensing pressure will lead to the increase of system refrigeration capacity and the decrease of compressor power consumption.

(2)If keep the compressor speed,evaporation pressure,antifreeze liquid flow rate of the hot antifreeze loop constant,change the condensing pressure,and alter the refrigerant mass flow rate to be inconstant,the refrigerant mass flow rate and the system refrigeration capacity will increase with the increase of condensing pressure.And the compressor consumption will increase more.

(3)If keep the system refrigeration capacity constant,and set the condensing pressure,the antifreeze liquid flow rate of hot antifreeze loop,the antifreeze liquid flow rate of cold antifreeze loop fixed,while only change the compressor speed,we can see that the bigger the compressor rotation is,the more the system refrigeration capacity and the compressor consumption are and the lower EER is.The compressor consumption is more sensitive than the system refrigeration capacity when the compressor is changed.

Above all,if the system refrigerant mass flow rate and the compressor rotation are fixed and only change the condensing pressure,lowering the condensing pressure will be better for the whole system;if keep the refrigerant mass flow rate and the condensing pressure constant and adjust the compressor rotation,higher compressor rotation will be good for the system refrigeration capacity and bad for EER;if just keep the compressor rotation constant,the system refrigeration mass flow rate will vary with the change of the condensing pressure,and higher condensing pressure will be good for the system refrigeration capacity and bad for EER.

[1] Severson M H,Squier S E.Cooling of aircraft electronic heat loads[P].USA:US5701055,1997-12-30.

[2] Dossat R J,Horan T J.Principles of refrigeration[M].New Jersey:Prentice Hall,2002:56-67.

[3] Huddle J,Chow L,Lei S,et al.Advantages of spray cooling for a diode laser module[C]//Power System Conference.San Diego,CA:SAE,2000.

[4] Ramalingam M,Mahefkey T,Donovan B.Fuel saving analysis and weapon platform thermal management options in a tactical aircraft[C]//Proceedings of 2003ASME International Mechanical Engineering Congress and Exposition.Washington DC:ASME,2003:246-254.

[5] Hale C,Hopkins K,Boyack C,et al.High heat flux dissipation for DEW applications[C]//SAE Transac-tions.NY:Society of Automotive Engineers,2004:2071-2086.

[6] Dorantes R,Lallemand A.Prediction of performance of a jet cooling system operating with pure refrigerants or non-azeotropic mixtures[J].Int J Refrigeration,1995,18(1):21-30.

[7] Khan J R,Zubair S M.Thermodynamic optimization of finite time vapor compression refrigeration systems[J].Energy Conversion and Management,2001,42(12):1457-1475.

[8] Yan X D,Song B Y,Yao M,et al.Experimental investigation on the heat transfer characteristic of twophase flow in an onboard vapor[J].Refrigeration and Air Conditioning,2008,22(6):8-11.

[9] Murthy S,Joshi Y,Nakayama W.Orientation independent two-phase heat spreaders for space constrained applications[J].Microelectronics,2003,34(12):1187-1193.

[10]Reyes M,Alonso D,Arias J R,et al.Experimental and theoretical study of a vapor chamber based heat spreader for avionics applications[J].Applied Thermal Engineering,2012,37(1):51-59.

[11]Kilicarslan A.An experimental investigation of a different type vapor compression cascade refrigeration system[J].Applied Thermal Engineering,2004,24(17/18):2611-2626.

[12]Abdullah A A A.Effect of evaporator temperature on vapor compression refrigeration system[J].Alexandria Engineering Journal,2011,50(4):283-290.

[13]Selvaraju A,Mani A.Experimental investigation on R134avapor injector refrigeration system[J].International Journal of Refrigeration,2006,29(7):1160-1166.

[14]Rigola J,Raush G,Perez-Segarra S D,et al.Numerical simulation and experimental validation of vapor compression refrigeration systems special emphasis on CO2trans-critical cycles[J].International Journal of Refrigeration,2005,28(8):1225-1237.

[15]Tunc I,Mehmet A.Light weight high performance thermal management with advanced heat sinks and extended surfaces[J].IEEE Transactions on Components and Packaging Technologies,2010,33(1):161-166.

Transactions of Nanjing University of Aeronautics and Astronautics2013年1期

Transactions of Nanjing University of Aeronautics and Astronautics2013年1期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- AIRCRAFT CONCEPT EVALUATION AND EFFECTIVENESS-BASED DECISION-MAKING

- SPH-BASED NUMERICAL ANALYSIS FOR GRANULAR MATERIAL MODEL OF SAND AND REGOLITH

- PREDICTION OF SURFACE ROUGHNESS FOR END MILLING TITANIUM ALLOY USING MODIFIED PARTICLE SWARM OPTIMIZATION LS-SVM

- SOFT IMAGE SEGMENTATION BASED ON CENTER-FREE FUZZY CLUSTERING

- SPATIAL REGULARIZATION OF CANONICAL CORRELATION ANALYSIS FOR LOW-RESOLUTION FACE RECOGNITION

- NOVEL HIGH-SPEED FPGA-BASED FFT PROCESSOR