Performance analysis of ammonia-water absorption/compression combined refrigeration cycle

Bao Shuaiyang Du Kai Cai Xingchen Niu Xiaofeng Wu Yunlong

(1School of Energy and Environment, Southeast University, Nanjing 210096, China)(2College of Urban Construction and Safety Engineering, Nanjing University of Technology, Nanjing 211816, China)

Performance analysis of ammonia-water absorption/compression combined refrigeration cycle

Bao Shuaiyang1Du Kai1Cai Xingchen1Niu Xiaofeng2Wu Yunlong1

(1School of Energy and Environment, Southeast University, Nanjing 210096, China)(2College of Urban Construction and Safety Engineering, Nanjing University of Technology, Nanjing 211816, China)

In view of different compressor adding ways in the ammonia-water absorption/compression combined refrigeration (AWA/CCR) cycle, combining the Schulz state equation of the ammonia-water solution, the theoretical analysis and calculations on two combination ways, by adding the compressor in the high-pressure area and in the low-pressure area, are conducted, respectively. The effects of several factors, including the evaporation temperatureTe, heat-source temperatureTh, as well as the cooling water temperatureTw, on the equivalent heat consumption in compressionqCW, heat consumption in absorptionqGand the system coefficient of performance (COP) are analyzed under the two combination configurations. The results show that the effect of the equivalent heat consumption in compression on the COP is less than that of the heat consumption in absorption. Besides, the compressor set in the high-pressure area uses more energy than that in the low-pressure area. Moreover, the compressor in the low-pressure area is superior to that in the high-pressure area with respect to the COP. Under the given intermediate pressure, there is an optimum heat-source temperature corresponding to the maximum COP of the AWA/CCR cycle.

ammonia-water absorption; compression refrigeration; combined refrigeration cycle; coefficient of performance (COP)

The ammonia-water absorption refrigeration system is driven by heat. This system has many advantages, such as comprehensive utilization of low grade thermal energy, less power consumption, strong adaptability to energy and environmentally friendly features[1]. In recent years, thanks to increasing global awareness of environmental protection and energy saving, ammonia-water absorption refrigerators have re-attracted researchers’ attention. However, due to the low COP, huge size and other drawbacks of ammonia-water absorption refrigerators, its applications and development are restricted[2]. Therefore, many researches on how to improve the performance of the ammonia-water absorption refrigeration system have been conducted[3-6].

The low temperature that an ammonia-water absorption refrigeration cycle can generate is influenced by many factors, such as the selection of process, the heat-source temperatureThand the cooling water temperatureTw[7]. When temperatures of heat-source and cooling water are fixed, the lowest evaporation temperatureTethat a single stage ammonia-water absorption refrigeration cycle can reach is limited. With the decrease in evaporation temperature, the deflation ratio of the system becomes smaller, and the unit performance turns worse sharply. Finally, when the deflation ratio is smaller than 0, the absorption refrigeration cycle cannot operate normally. To ensure the normal operation, the heat-source temperature must be raised, which is contradictory to the intention of effective utilization of low grade heat source by absorption refrigeration. Some researchers have studied the performance and the detailed configuration of such a combined refrigeration cycle. In Ref.[8], the compressor was added in the high-pressure area of the ammonia-water absorption refrigeration cycle (between the generator and the condenser). It is found that the combined system has advantages both in absorption and compression cycle, and the novel combined system is more suitable for obtaining low temperature with low-grade waste heat. Besides, heat consumption and power consumption can be reduced greatly. By adding a roots blower to the low-pressure area (between the evaporator and the absorber), Du and Dong[9]found that the COP and the refrigerating capacity of the combined refrigeration cycle increase significantly and lower refrigeration temperature is obtainable as compared to the single-stage ammonia-water absorption refrigeration. Zhao et al.[10]proposed to add the compressor in the low-pressure area and the results show that under the same evaporation temperature, the heat-source temperature can be reduced significantly in the ammonia-water absorption/compression combined refrigeration cycle. Cai et al.[11]presented that the temperature of driving heat-source can be reduced by adding a compressor to the low-pressure area in the double-effect ammonia-water absorption refrigerator. When the evaporation temperature is -20 ℃, the thermal coefficient is 20% higher than that of the single-stage cycle. Ramesh et al.[4,12]proposed a new cycle named GAXAC (generator-absorber-exchange absorption compression) by adding a compressor in the low-pressure area of the GAX (generator-absorber heat exchange) cycle, and it was found that the COP of the GAXAC cycle can be increased by 30%.

Previous studies have established that the compressor-assisted absorption refrigeration cycle can reach a wider deflation ratio, a lower circulation ratio, and a higher COP as compared with the conventional cycle. However, different combining ways lead to different operation characteristics in the cycle. It is still uncertain which absorption/compression combining way has better thermodynamic performance by adding the compressor in the high-pressure area or in the low-pressure area. In the current study, in order to obtain a detailed and instructive comparison between these two ways, the theoretical analysis and calculations of the ammonia-water absorption/compression combined refrigeration (AWA/CCR) system with the two combining configurations are performed, respectively. The effect of several factors, including the evaporation temperatureTe, heat-source temperatureThas well as the cooling water temperatureTw, on the equivalent heat consumption in compressionqCW, heat consumption in absorptionqGand the system COP are analyzed in the two combination configurations.

1 Characteristics of AWA/CCR System with Different Combining Configurations

As shown in Fig.1, both configurations are two-stage process systems with a compressor being added in the single-stage ammonia-water absorption refrigeration system. One stage is the absorption type, and the other is the compression type. The difference between the systems lies in the position of the installation of the compressor. If the compressor is installed on the pipeline link to the inlet of the absorber, as shown in Fig.1(a), the compression process will be performed at the low-pressure stage and the absorption process will be at the high-pressure stage, which is called the low-pressure compression process (LP for short). By contrast, when the compressor is installed on the pipeline link to the inlet of the condenser, as shown in Fig.1(b), the process of such configuration is called the high-pressure compression process (HP for short)[13].

In the low-pressure compression process, due to supercharging by the compressor, the absorption pressure of the cycle increases. Under a fixed temperature of cooling water, the concentration of the aqueous solution of ammonia increases after absorption, and the deflation ratio of solution circulation increases, resulting in the decrease in heat consumption of the whole cycle. However, setting the compressor in the low-pressure area also has neg-ative effects: the specific volume of the refrigerant vapor at the inlet of the compressor will be larger under a low pressure, so a compressor with a large volume will be required. Moreover, both the compression ratio and power consumption rise when the refrigeration temperature goes down. In the high-pressure compression process, the pressure of generator reduces due to the partial pressure of the compressor. Therefore, the concentration of the aqueous solution of ammonia decreases after generation while the deflation ratio of solution circulation increases, which finally leads to a drop in the heat consumption of the absorption cycle. In addition, since the specific volume of refrigerant vapor at the inlet of the compressor is relatively small, the corresponding volume of the compressor can be smaller. Furthermore, the decrease in evaporating temperature may not affect the power consumption directly. In general, under both combining configurations, the deflation ratio of solution increases, and the performance of the whole system improves. However, each configuration has its advantages and disadvantages, the power consumption of the compressor and heat consumption of the generator should be considered together when making analysis. Thus, the comparison of the thermodynamic performance between the two configurations can be obtained appropriately.

G—generator;Ex—solution heat exchanger;P—ammonia pump A—absorber;CW—compressor;E—evaporator;C—condenser S—supercooler

Fig.1 Schematic diagram of the ammonia-water absorption/compression combined refrigeration cycle.(a) Low-pressure stage; (b) High-pressure stage

2 Thermodynamic Calculation

The thermodynamic calculation of the AWA/CCR cycle is based on the following three principles: the Schulz[14]state equation of the ammonia-water solution, the mass conservation equation and the energy conservation equation. To simplify the calculation, we assume that

1) The high and low-pressure compression processes are in thermal equilibrium and steady-flow state;

2) The solution which flows out from the generator/absorber and the refrigerant which flows out from the condenser/evaporator are in saturated state;

3) The pressure drop of fluid in pipeline and equipment is negligible;

4) The pinch point temperature difference in heat exchangers is 5 ℃;

5) The heat utilization ratio of the solution heat exchanger is 0.95;

6) The distillation efficiencyλis assumed to be 0.8 and the outlet state of the generator (point 5) is pure ammonia;

7) The compression efficiency of the compressor is 0.7;

8) The thermo-electric conversion efficiencyηis 0.35[15].

In order to simplify calculation, all the calculations are based on a 1 kg/s generation rate of rectification column, that is, all the results obtained in this paper correspond to per unit mass of refrigerant ammonia. The temperature, pressure and enthalpy of each state point as shown in Fig.1 can be obtained by setting the material balance equation, the energy balance equation and the phase equilibrium equation of every piece of equipment in the system. Accordingly, the unit heat load in the equipment and the power consumption of the compressor can be calculated as follows.

The evaporator heat load per unit mass is

qE=h8-h6a

(1)

whereqEis the evaporator heat load per unit mass;h8andh6aare the specific enthalpy of state point 8 and 6a, respectively.

The reflux condenser heat load per unit mass is

(2)

The generator heat load per unit mass is

qG=h5-h2+f(h2-h1a)+qRC

(3)

whereqGis the generator heat load per unit mass;fis the circulation ratio of the absorption cycle;h1aandh2are the specific enthalpy of state point 1a and 2, respectively.

The compressor power consumption per unit mass is

(4)

wherewis the compressor power consumption per unit mass;PinandPoutare the pressures of the inlet and outlet of the compressor, respectively;vinis the specific volume at the inlet of the compressor;kis the compression index of ammonia.

In order to make the evaluation of the power consumption more reasonable, the index of thermo-electric conversion efficiency is adopted in this study, which is used to convert the unit power consumption of the compressor to the equivalent unit heat consumption:

(5)

whereqCWis the equivalent unit heat consumption of the compressor, andηis the thermo-electric conversion efficiency.

Therefore, the total primary energy consumption of the AWA/CCR cycle per unit mass is

qT=qG+qCW

(6)

whereqTis the total primary energy consumption of the AWA/CCR cycle per unit mass.

After obtaining the unit heat load of all the devices, the COP of the AWA/CCR cycle can be defined as

(7)

3 Results and Discussion

Since the pressure drop of fluid in pipeline and equipment is ignored, there are only three pressure types in the AWA/CCR cycle: the condensing pressurePc, the intermediate pressurePmand the evaporation pressurePe. Among these three pressure types, both the condensing pressurePcand the evaporating pressurePeare determined by the operation conditions, while the intermediate pressurePmis an adjustable parameter, as in the two-stage compression refrigeration system. For the convenience of analysis,Pmis determined by the method, which is similar to that used in the two-stage compression refrigeration system. That is, the compression ratio in the high-pressure stage is equal to that in the low-pressure stage:

(8)

whereβis the compression ratio.

Therefore, according to Eq.(8),Pmis determined as

(9)

In the low-pressure compression process,Pmrefers to the discharge pressure of the compressor, which is equal to the absorption pressure in the absorber. At the same time, it represents the suction pressure of the compressor in the high-pressure compression process, namely, the generation pressure in the generator. As discussed in Section 1, compared to the single stage ammonia-water absorption refrigeration cycle, the deflation ratio of the solution is extended and the circulation ratio is decreased. So the heat consumption of the the AWA/CCR system is decreased. However, due to the addition of the compressor, the power consumption of the system increases. Besides, the power consumption of the compressor varies with the change of the intermediate pressure, and the heat consumption in absorption is also affected by the intermediate pressure. Therefore, in order to make the power consumption of the compressor identical to the heat consumption in terms of the quality of energy, the power consumption of the compressor is converted to the equivalent heat consumption as shown in Eq.(5). Finally, the performance of the AWA/CCR cycle is analyzed from the perspective of the system primary energy consumption.

3.1 Effect of evaporation temperatureTe

Since the unique corresponding relationship of the evaporation pressurePeof the refrigerant and the evaporating temperatureTe, different evaporation temperatures may lead to different intermediate pressures, as calculated by Eq.(9). The effects of the evaporation temperature on the variables that reflect the performance of the two processes, such as the equivalent heat consumption of compressorqCW, the heat consumption of generatorqG, total primary energy consumptionqT, circulation ratiof, actual reflux ratio of rectification columnRand COP, are shown in Figs.2 to 4. The calculation in the figures is on the condition that the heat source temperatureThand cooling water temperatureTware 140 and 32 ℃, respectively.

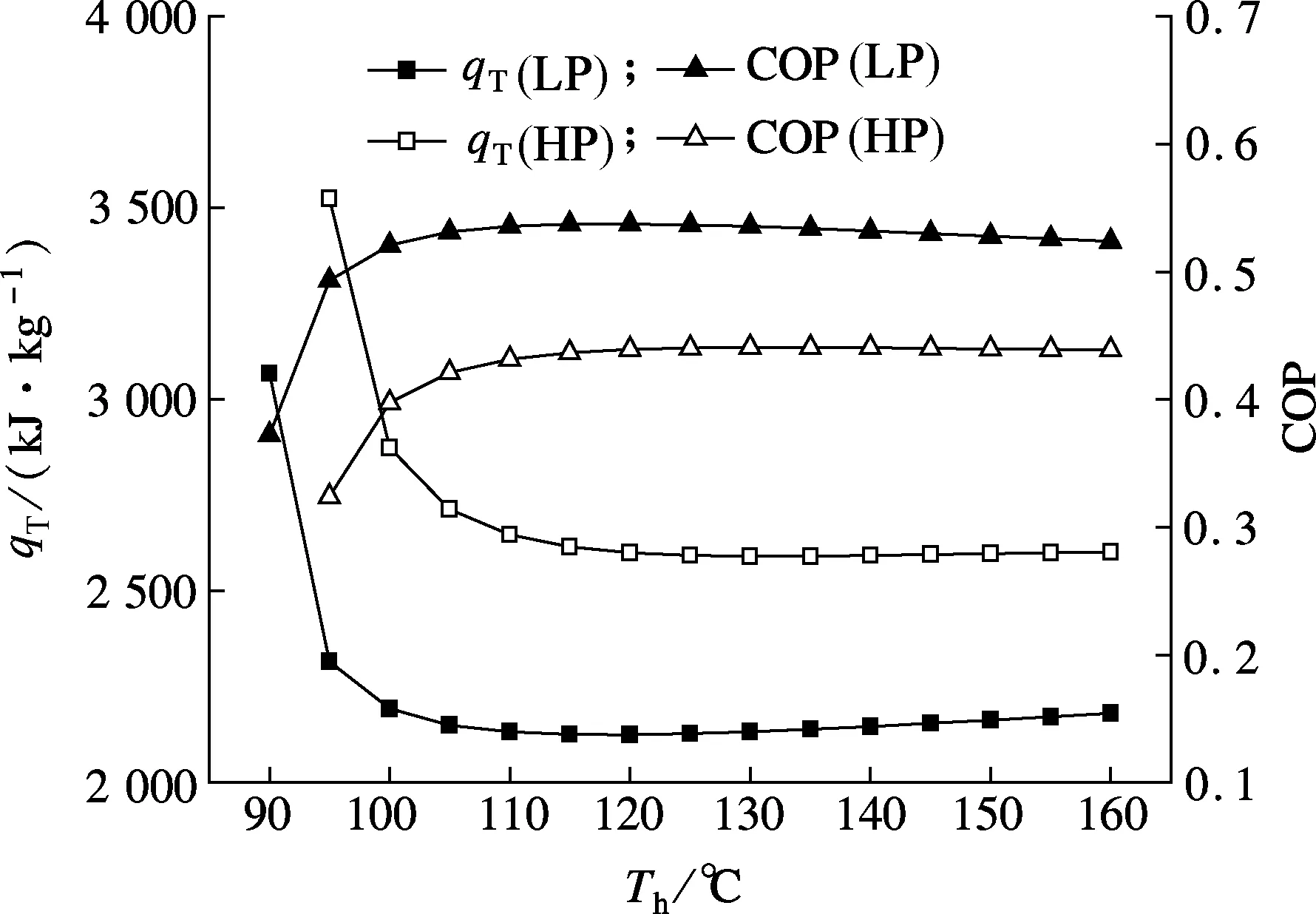

Fig.2 qTand COP changing withTein high- and low-pressure compression processes (Th=140℃,Tw=32℃)

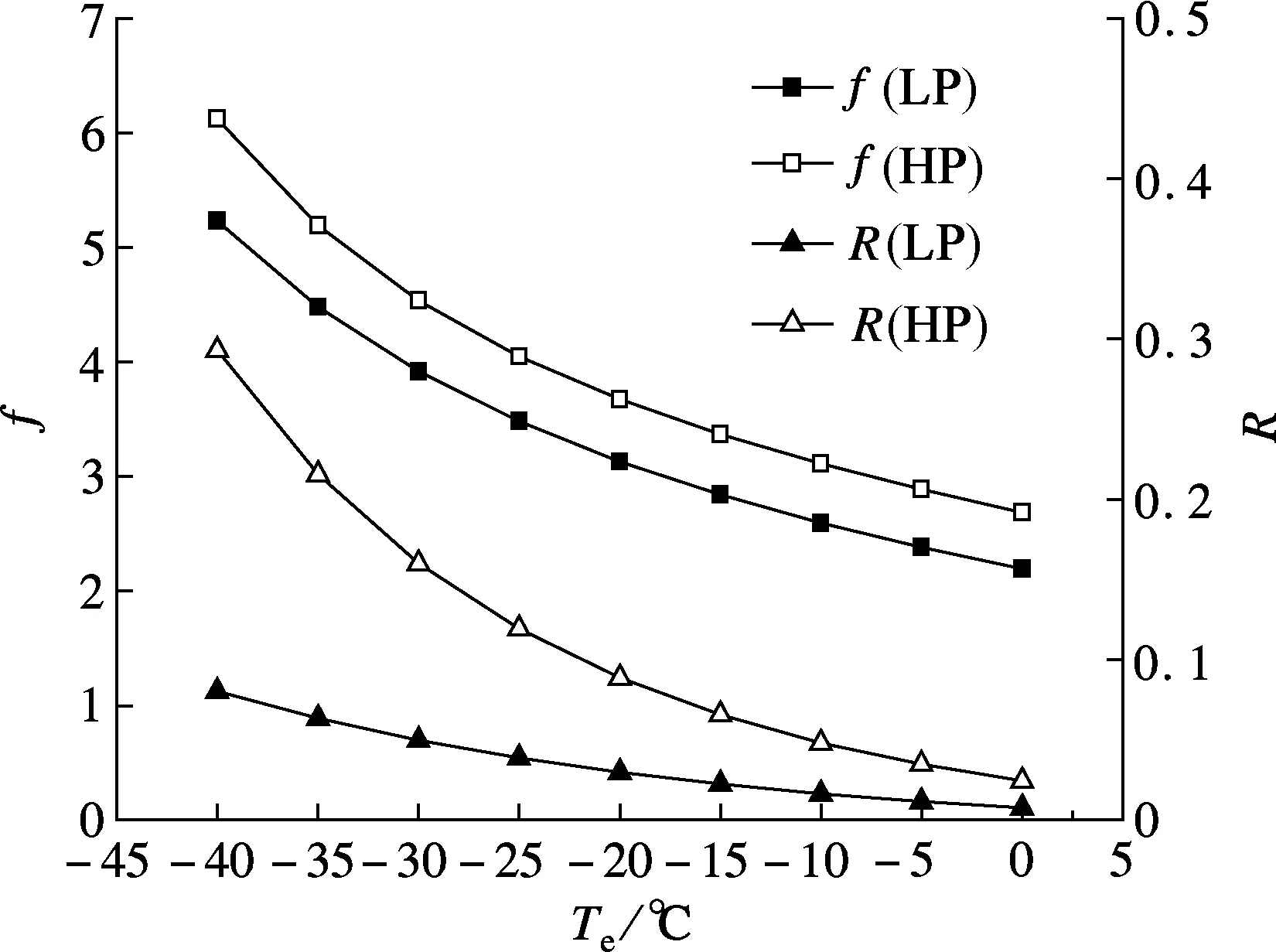

Fig.3 fandRchanging withTein high- and low-pressure compression processes (Th=140℃,Tw=32℃)

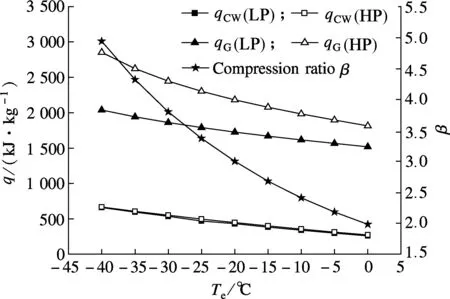

Fig.4 qCW,qGandβchanging withTein high- and low-pressure compression processes (Th=140℃,Tw=32℃)

As the compression ratioβof the two processes is identical, the difference in equivalent heat consumption is not so much when the two processes are under the same operating condition. As shown in Fig.4, the compression ratioβof the AWA/CCR cycle decreases gradually with the increase in evaporation temperatureTe, and then the equivalent heat consumption of the compressorqCWin both processes decreases. By Eqs.(2) and (3), it can be found that the unit heat consumption of the generator depends on the circulation ratiofand the actual reflux ratio of rectification columnR. Fig.3 shows that the circulation ratio in the absorption cycle and the actual reflux ratio of the rectification column decrease in both processes when the evaporation temperature increases, and they are greater in the high-pressure compression process than in the low-pressure one. Moreover, the increase in the evaporation temperature also leads to the narrowing difference in actual reflux ratio between the two processes. Therefore, the heat consumption of the generator in the absorption cycle decreases along with the rise of the evaporation temperature, and compared with the low-pressure compression process, the high-pressure one consumes more heat.

Based on the analysis above and Fig.2, when the equivalent heat consumption of the compressor and the heat consumption in the absorption cycle are considered together, the total primary energy consumption of two processes decreases with the evaporation temperature increasing, and the total primary energy consumption in the high-pressure compression process is greater than that of the low-pressure one. Furthermore, the lower the evaporation temperature, the larger the difference between them will be. Thus, the COP in the high-pressure compression process is always smaller than that in the low-pressure one under the above conditions.

In addition, as shown in Fig.4, when the evaporation temperatureTeis -20℃, the heat consumption in the absorption cycle is five times higher than the compressor equivalent heat consumption in the low-pressure compression process, while in the high-pressure compression process, such value of difference reaches about 5.9. Therefore, the heat consumption in an absorption cycle plays a more important role in affecting the COP of the AWA/CCR cycle compared with the equivalent heat consumption of the compressor.

3.2 Effect of heat-source temperatureTh

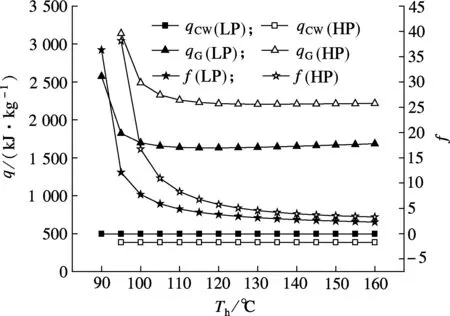

When the evaporation temperatureTeis -20℃ and the cooling water temperatureTwis 32℃, the intermediate pressurePmcalculated by Eq.(9) is 0.52 MPa. Under these designing conditions, Fig.5 and Fig.6 show the effect of the heat-source temperature on the related variables of the two processes, including the equivalent heat consumption of the compressorqCW, the heat consumption of the generatorqG, the total primary energy consumptionqT, the circulation ratiofand the COP.

As shown in Fig.6, when the intermediate pressurePmmaintains constant, the heat-source temperatureThhas little influence on the equivalent heat consumption of the compressor. The reason is that the change of heat source temperature only affects the solution concentration in the absorption cycle while exerting no effect on the inlet and outlet variables of the compressor. When the heat-source temperature is below 110 ℃, the heat consumption in an absorption cycle gradually increases in both processes due to the decrease of heat-source temperature, and when the temperature drops below a certain value, the heat consumption in an absorption cycle increases sharply. If the heat-source temperature drops further, the cycle cannot work properly theoretically. This is because the deflation ratio of the solution in an absorption cycle decreases with the decrease of heat-source temperature, as shown in Fig.6, which leads to a rapid increase in the circulation ratio.

When the heat-source temperature is lower than a certain value, the deflation ratio turns to be zero. Therefore, when the system works on the conditions shown in Fig.6, the minimum temperature of the driving heat source cannot be lower than 90℃ in the low-pressure compression process, whereas it cannot be lower than 95℃ in the high-pressure compression process. For the single-stage ammonia-water absorption refrigeration, the calculated minimum temperature of the driving heat source is 135 ℃.When the heat-source temperature is higher than 110℃, the heat consumption in an absorption cycle remains almost constant with very slight increase when the heat-source temperature increases. This is because with the increase of heat-source temperature, more water is evaporated from the solution, which results in a slow increase in the rectifying load. In addition, as shown in Fig.6, the high-pressure compression process has a higher circulation ratio and it apparently needs more heat. Therefore, compared with the high-pressure compression process, the low-pressure one has a more broadly heat-source temperature range.

Fig.5 qTand COP changing withThin high- and low-pressure compression processes (Te=-20 ℃,Tw=32 ℃,Pm=0.52 MPa)

Fig.6 f,qCWandqGchanging withThin high- and low-pressure compression processes(Te=-20 ℃,Tw=32 ℃,Pm=0.52 MPa)

When the compressor equivalent heat consumption and heat consumption of the generator are considered together, as shown in Fig.5, the COP of the two processes initially increases to a certain value and then decreases slowly with the increase of heat-source temperature. Therefore, an optimum heat-source temperature exits in each process, at which the system can obtain the maximum COP.

3.3 Effect of cooling water temperatureTw

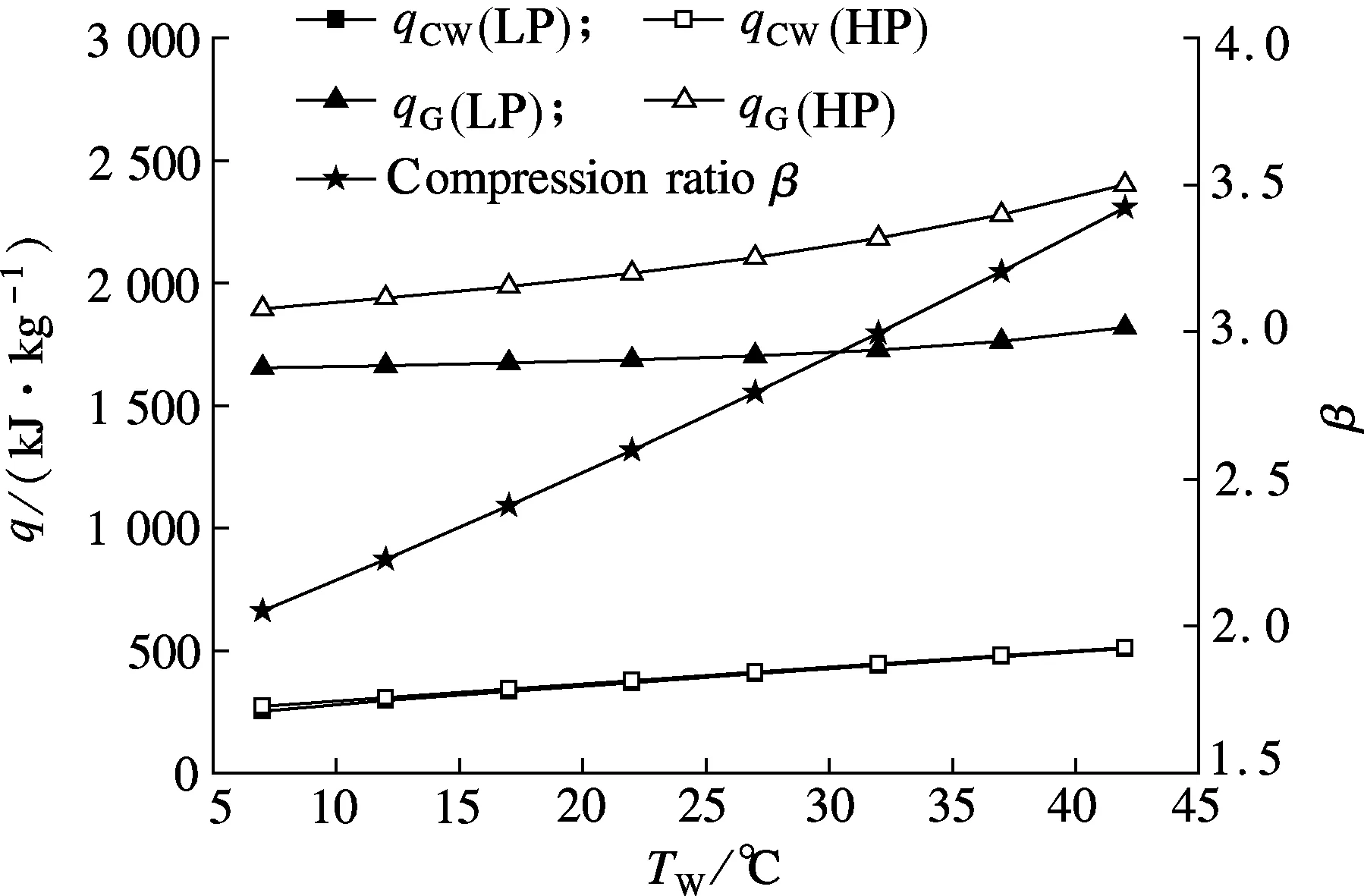

Figs.7 to 9 show the impact of the temperature of cooling water on the system performance, which is obtained under the condition that the evaporation temperatureTeis -20 ℃ and the heat-source temperatureThis 140℃.

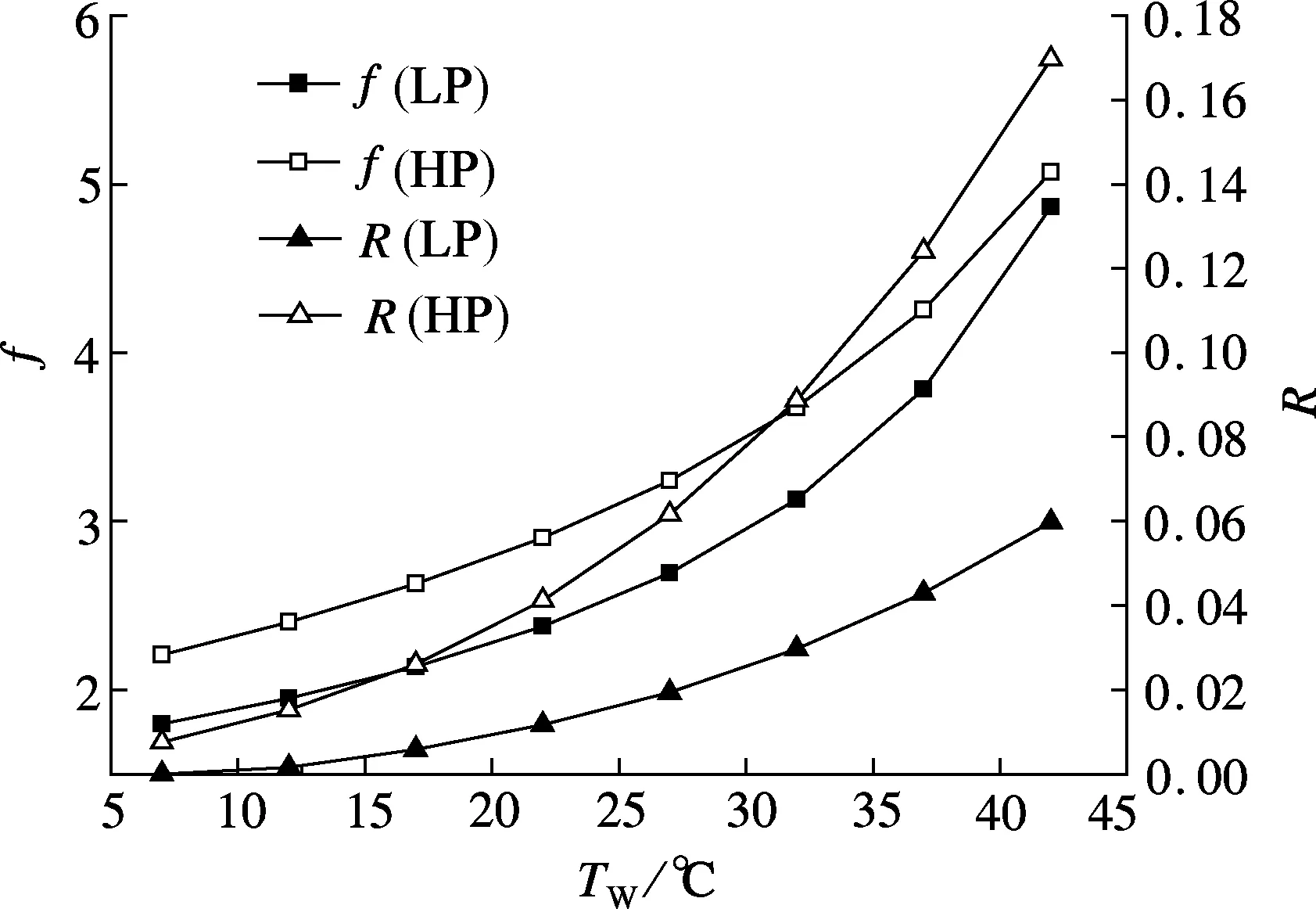

As shown in Fig.8, with the increase in the cooling water temperature, the circulation ratiofand the actual reflux ratio of rectification columnRincrease in both processes, and both of them are greater in the high-pressure compression process than in the low-pressure one. The reason can be explained as follows: with the increase in the cooling water temperature, the condensation effect in the condenser degrades, and thus the condensation pressurePcincreases, which results in the increase of intermediate pressurePm. In addition, the increase in the cooling water temperature can also lead to the decrease of the solution concentration after absorption in the absorption cycle. In the low-pressure compression process, higher condensing pressure directly results in higher solution concentration after generation in an absorption cycle. While in the high-pressure compression process, higher condensing pressure leads to higher intermediate pressure, which can result in a higher solution concentration indirectly after generation, and then the deflation ratio decreases and the circulation ratio increases consequently.

Fig.7 qTand COP changing withTwin high- and low-pressure compression processes (Te=-20℃,Th=140℃)

Fig.8 fandRchanging withTwin high- and low-pressure compression processes (Te=-20℃,Th=140℃)

Fig.9 qCW,qGandβchanging withTwin high- and low-pressure compression processes (Te=-20℃,Th=140℃)

According to Eqs.(2) and (3), the heat consumption of the generator in the high-pressure compression process is higher than that in the low-pressure one. Moreover, it increases when the cooling water temperature rises. Under the same working condition, the high- and low-pressure compression processes have the identical compression ratio, and thus the compressor equivalent heat consumptions of two processes are almost the same. Fig.9 shows that the compression ratioβof the cycle increases with the increase of cooling water temperature, and the compressor equivalent heat consumption increases in both processes. When both the equivalent heat consumption of the compressor and the heat consumption of the generator are taken into consideration, the total primary energy required in the low-pressure process is less, just as shown in Fig.7. Besides, the COP in both processes decreases when the cooling water temperature increases, and it is higher in the low-pressure process.

In addition, from Fig.4, Fig.6 and Fig.9, it can be seen that, under the given conditions, the equivalent heat consumptionsqCWof the high- and low-pressure compression processes are nearly the same. The heat consumptionqhin the absorption cycle is more influential on thermodynamic performance than the equivalent heat consumption of the compressor.

4 Conclusions

1) Heat consumptionqhplays a more important role on thermodynamic performance than the equivalent heat consumption of compressorqCWdoes in the AWA/CCR cycle. There are not so many differences in the compressor equivalent heat consumptionqCWbetween the high- and low-pressure processes under the same operation conditions. Compared with the high-pressure compression process, the low-pressure one seems to be more suitable for the conditions of low evaporation temperature, slightly higher cooling water temperature and much lower grade heat, which expands the applications of ammonia-water absorption refrigeration.

2) Under the intermediate pressure adopted in this paper, the COP of the AWA/CCR cycle increases along with the increase of the evaporating temperatureTe, while it decreases with the increase of the cooling water temperatureTw. Moreover, the COP increases with the increase in heat-source temperatureThfirst, but the effect of heat-source temperature on the system performance weakens gradually, and then the COP has a tendency of decline when the heat-source temperatureThis over a certain value.

3) The high-pressure compression process consumes more primary energy than the low-pressure one does under the same design conditions; therefore, the COP of low-pressure compression process is greater than that of the high-pressure compression process.

[1]Xu S M. The research progress of absorption refrigeration cycle and refrigerants (I): high COP of absorption refrigeration (heat pump) cycle[J].FluidMachinery, 1999, 27(2):57-61. (in Chinese)

[2]Habib K, Saha B B, Chakraborty A, et al. Performance evaluation of combined adsorption refrigeration cycles[J].InternationalJournalofRefrigeration, 2011,34(1):129-137.

[3]Hong D, Tang L, He Y, et al. A novel absorption refrigeration cycle[J].AppliedThermalEngineering, 2010, 30(14):2045-2050.

[4]Ramesh K A, Udayakumar M. Simulation studies on GAX absorption compression cooler[J].EnergyConversionandManagement, 2007, 48(9): 2604-2610.

[5]Jawahar C P, Saravana R. Generator absorber heat exchange based absorption cycle—a review[J].RenewableandSustainableEnergyReviews, 2010, 14(8):2372-2382.

[6]Demirkaya G, Padilla R V, Goswami D Y, et al. Analysis of a combined power and cooling cycle for low grade heat sources[J].InternationalJournalofEnergyResearch, 2011, 35(13):1145-1157.

[7]Du K, Liao J M. Performance analysis of ammonia-water absorption refrigeration GAX cycle[J].JournalofSoutheastUniversity:NaturalScienceEdition, 2005, 35(5):766-768. (in Chinese)

[8]Bao H L, Yang S W. Research on ammonia-water absorption/compression refrigeration system[J].FluidEngineering, 1987(6):57-61. (in Chinese)

[9]Du K, Dong J X. Research on boost absorption of ammonia-water absorption refrigeration system[J].FluidMachinery, 2000, 28(8): 54-55. (in Chinese)

[10]Zhao Z C, Zhang X D. Thermal performance analysis of ammonia absorption/compression refrigeration cycle driven by low temperature waste heat[J].ChemicalIndustryandEngineeringProgress, 2009, 28(S1):459-462. (in Chinese)

[11]Cai X C, Du K, Li Y J. Performance analysis of boosted two-stage ammonia-water absorption refrigeration system[J].JournalofChemicalIndustryandEngineering, 2012, 63(S2):170-175. (in Chinese)

[12]Ramesh K A, Udayakumar M, Saravanan R. Heat transfer studies on a GAXA (generator-absorber-exchange absorption compressor) cooler[J].AppliedEnergy, 2009, 86(10):2056-2064.

[13]Yang S W. The basic theory and design of ammonia-water absorption refrigeration cycle: performance and process[J].FluidEngineering, 1990(3): 56-63. (in Chinese)

[14]Schulz S C G. Equations of state for the system ammonia-water for use with computers[C]//Proceedingsofthe13thInternationalCongressofRefrigeration. Washington DC, USA, 1971:431-436.

[15]Wang Y J, Ou R H, Chen H X. Boosting double effect absorption refrigeration circle using heat and mass transfer separation absorber[J].FluidMachinery, 2007, 35(5):75-78. (in Chinese)

氨水吸收/压缩复合制冷循环性能分析

鲍帅阳1杜 垲1蔡星辰1牛晓峰2武云龙1

(1东南大学能源与环境学院, 南京 210096) (2南京工业大学城市建设与安全工程学院, 南京 211816)

针对氨水吸收/压缩复合制冷循环的方式不同,结合Schulz氨水溶液状态方程,分别对压缩机处于系统高压区和低压区2种不同的组合方式进行了理论分析计算.分析了在给定中间压力下,蒸发温度Te、热源温度Th和冷却水温度Tw对2种组合方式下压缩机当量热耗量qCW、热源耗热量qG和循环性能系数COP的影响.结果表明:压缩机当量热耗量对循环性能系数的影响要低于热源耗热量的影响;压缩机处于系统高压区时循环的一次用能量要明显高于压缩机处于系统的低压区;压缩机处于系统低压区时循环性能要优于压缩机处于系统的高压区.当中间压力给定时,存在一个最佳热源温度,使得氨水吸收/压缩复合制冷循环的性能系数取得最大值.

氨水吸收式;压缩式制冷;复合制冷循环;性能系数

TB616

The National Natural Science Foundation of China (No.51176029).

:Bao Shuaiyang, Du Kai, Cai Xingchen, et al.Performance analysis of ammonia-water absorption/compression combined refrigeration cycle[J].Journal of Southeast University (English Edition),2014,30(1):60-67.

10.3969/j.issn.1003-7985.2014.01.012

10.3969/j.issn.1003-7985.2014.01.012

Received 2013-08-19.

Biographies:Bao Shuaiyang(1990—),male,graduate; Du Kai(corresponding author), male, doctor, professor, du-kai@seu.edu.cn.

Journal of Southeast University(English Edition)2014年1期

Journal of Southeast University(English Edition)2014年1期

- Journal of Southeast University(English Edition)的其它文章

- Speech emotion recognitionusing semi-supervised discriminant analysis

- Shape retrieval using multi-level included anglefunctions-based Fourier descriptor

- Optimization of cross-coupling reaction for synthesis of antitumor drug vismodegib

- Flexural behaviors of FRP strengthened corroded RC beams

- Notes on well-posedness for the b-family equation

- Icon memory research under different time pressures and icon quantities based on event-related potential