基于组成特性的肉骨粉种属鉴别标志性变量挖掘

高 冰,王梦妍,姚玉梅,高 菲,韩鲁佳,刘 贤

基于组成特性的肉骨粉种属鉴别标志性变量挖掘

高 冰,王梦妍,姚玉梅,高 菲,韩鲁佳,刘 贤※

(中国农业大学工学院,北京 100083)

为了全面表征不同种属肉骨粉的组成特性,并进一步挖掘肉骨粉种属鉴别标志性变量,研究基于166个来源可靠的不同种属肉骨粉样本(猪、鸡、牛、羊源),从基本组分、元素组成、脂肪酸组成和氨基酸组成4个方面全面获取物料组成特性信息。对比分析不同种属肉骨粉的69个组成变量,其中31个组成变量在种属间差异性显著(<0.05)。主成分分析(Principal Component Analysis,PCA)结合偏最小二乘判别分析(Partial Least Square-Discriminant Analysis,PLS-DA)对肉骨粉种属间特异性进行探索性分析。结果表明,元素组成和脂肪酸组成可以为猪、鸡、牛、羊肉骨粉提供特异性组成标志变量;氨基酸组成是反刍动物肉骨粉的特异性组成标志变量来源。综合PLS-DA和单因素方差分析结果,以VIP值大于1,<0.05为指标,研究获取了不同种属肉骨粉之间的特异性组成标志变量,分别为:C10∶0、C18∶0、C18∶2n6c(猪肉骨粉);Ca、K、Zn、C18∶0、C18∶2n6c(鸡肉骨粉);Sr、C14∶1、C17∶0、C17∶1、C18∶0、C18∶2n6t(牛肉骨粉);H、Mg、Sr、C10∶0、C16∶0、C17∶0、C17∶1、C18∶0(羊肉骨粉);Sr、Ba、C14∶1、C17∶0、C15∶0、C17∶1、C18∶0、C18∶2n6t、C18∶2n6c、丝氨酸(反刍动物肉骨粉);K、Zn、C18∶0、C18∶2n6c(哺乳动物肉骨粉)。该研究可以为肉骨粉种属鉴别方法及其多元应用机理分析提供数据支持,并可以为肉骨粉多元应用细化至不同种属提供理论基础。

主成分分析;脂肪酸;氨基酸;肉骨粉;不同种属;组成特性;对比分析;变量挖掘

0 引 言

肉骨粉是由畜禽屠宰废弃物加工成的动物蛋白产品,曾作为重要的蛋白饲料在养殖领域广泛使用[1]。在疯牛病(牛脑海绵状病)爆发前,对于肉骨粉的研究主要为其作为饲料的特性研究[2-3]。反刍动物饲用同源肉骨粉是传播疯牛病的主要途径[4],因此,为了从源头上控制朊病毒(疯牛病的病原体)的传播,世界各国纷纷制定了法律法规对饲用肉骨粉进行管控[5]。为了防止同源相食,合理地利用肉骨粉资源,肉骨粉种属鉴别研究具有一定的意义。

在肉骨粉严格管控期间,相关研究集中在肉骨粉的无害化处理,主要利用肉骨粉的热解、燃烧特性[6-7]及其残渣的吸附特性[8]。近几十年来,肉骨粉作为一种生物质资源,在材料[9-11]、燃料[12-14]、肥料[15-16]、饲料[17-18]、催化剂[19]、厌氧发酵[20-21]、吸附剂[22-25]等领域得到广泛研究与利用。

肉骨粉组成特性复杂,不同的组成有不同的利用途径[26],例如肉骨粉用作肥料、吸附剂和催化剂主要利用其元素组成中的钙和磷;材料、饲料和厌氧发酵主要利用肉骨粉的脂质和氨基酸组成。肉骨粉种属鉴别相关指纹图谱研究表明不同种属肉骨粉在化学组成上具有特异性与差异性[27-30]。有研究对肉骨粉的元素和氨基酸组成进行了表征分析[31-34],肉骨粉组成特性的表征可以为肉骨粉组成的工程利用数据与理论基础,但是并未在不同种属层面进行对比分析。因此,不同种属肉骨粉组成特性表征研究是必要的。

本研究全面表征肉骨粉的组成特性,对比种属间的差异性,并结合化学计量学方法,挖掘肉骨粉种属间具有标志性的组成变量。该研究可以为肉骨粉种属鉴别方法及其多元应用机理分析提供数据支持,并可以为肉骨粉多元应用细化至不同种属提供理论基础。

1 材料与方法

1.1 肉骨粉样本的收集与制备

1.2 基本组分测定

测定全部166个肉骨粉样本的基本组分,其中:含水率根据GB/T 6435—2014测定,称取5 g样本置于干燥皿内,在(103±2)℃的干燥箱中烘干至恒质量;粗灰分的含量根据GB/T 6438—2007测定,称取1 g样本置于坩埚中,在550 ℃的马弗炉中灼烧3 h;粗蛋白的含量根据GB/T 6432—94,并通过凯氏定氮仪(KjeltecTM 2300,丹麦FOSS公司)测定;粗脂肪的含量根据GB/T 6433—2006,并通过全自动脂肪抽提仪(SoxtecTM 2050,丹麦FOSS公司)测定。

1.3 元素检测

肉骨粉基质复杂,骨成分与非骨成分的元素组成差异较大[34],为了挖掘肉骨粉种属间元素组成差异,采用欧盟标准方法(EC/51/2013)制备提取肉骨粉中骨颗粒,测定14种主要元素(C、H、O、N、S、Ca、P、Na、Mg、K、Fe、Zn、Sr、Ba)。每个骨颗粒样本进行2次平行测定,分析样本数量总计37个(猪源样本14个、鸡源样本9个、牛源样本9个、羊源样本5个)。样本的C、H、N、S元素含量可直接通过元素分析仪(Vario Macro,德国Elemental公司)测定,且按标准方法(ASTM E1755-01,2007)测定样本灰分含量后,通过差减法计算获得O元素含量[30];Ca、Na、Mg、K、Fe、Zn、Sr、Ba元素含量在样本经微波消解后,通过电感耦合等离子体质谱仪(ICP-MS 7500,美国Agilient公司)测定;P元素含量通过连续流动分析仪(AutoAnalyzer3,德国Bran+Luebbe公司)测定。

1.4 脂肪酸检测

肉骨粉样本的脂质成分使用全自动脂肪测定仪(SoxtecTM 2050,丹麦FOSS公司)提取,并置于4℃冰箱,保存备用。脂质样本经皂化、甲酯化、脱水后,得到脂肪酸甲酯,通过气相色谱仪(GC-2014C,日本岛津公司)进行脂肪酸种类及含量测定。分析样本数量总计77个(猪源样本21个、鸡源样本22个、牛源样本17个、羊源样本17个)。实验室测定仪器为气相色谱,参数如下:采用氢离子火焰检测器(FID,日本岛津公司);石英毛细管柱(RT-2560,Restek公司)长度100 m,内径0.25 mm,膜厚0.2m。色谱分析条件如下[36]:进样量1L,进样口温度为225 ℃;分流比为10:1;初始温度100 ℃,保持2 min,以4 ℃/min速率升温至160 ℃,以2 ℃/min的速率升温至190 ℃,保持15 min,以2 ℃/min的速率升温至200 ℃,以3 ℃/min的速率升温至230 ℃,保持25 min;检测温度250 ℃,载气为氮气(纯度为99.999%),氢气流速为40 mL/min,氮气流速为12 mL/min,空气流速为400 mL/min,尾吹流速为60 mL/min。每个样本做3次平行测定。脂肪酸甲酯混合标准品(47885-U)购买于美国Sigma-Aldrich公司。

1.5 氨基酸检测

色氨酸利用分光光度计按照GB/T 15400—94进行测定;胱氨酸和蛋氨酸用L8900氨基酸分析仪(日本日立公司)按照GB/T 15399—94进行测定;天冬氨酸、苏氨酸、丝氨酸、谷氨酸、甘氨酸、丙氨酸、缬氨酸、异亮氨酸、亮氨酸、酪氨酸、苯丙氨酸、赖氨酸、组氨酸、精氨酸和脯氨酸利用L8900氨基酸分析仪(日本日立公司)按照GB/T 18246—2000进行测定;分析样本数量总计25个(猪源样本13个、鸡源样本6个、牛源样本4个、羊源样本2个)。

1.6 统计分析方法

研究使用SPSS20.0单因素方差分析法(中的Duncan多重检验法对不同种属肉骨粉组成差异进行统计学分析。置信水平设置为95%(<0.05)。采用主成分分析(Principal Component Analysis,PCA)[37]和偏最小二乘判别分析(Partial Least Square-Discriminant Analysis,PLS-DA)[38]基于组成变量信息对肉骨粉种属间特异性进行探索性分析与定性判别分析。采用Kennard-Stone算法进行校正集和预测集的划分,75%的样本用来建立校正模型,25%的样本用来模型验证。其中,PLS-DA模型的灵敏度(Sensitivity)、特异度(Specificity)越接近于1,分类误差越接近于0,说明肉骨粉种属间特异性越强[39],变量投影重要性得分(Variables Important In Projection,VIP)大于1的变量被视为导致肉骨粉种属间差异的主要变量[40]。2种方法均使用工具包PLS toolbox 8.0,在Matlab中实现。灵敏度和特异度计算公式如下

Sensitivity=TP/(TP+FN)(1)

Specificity=TN/(TN+FP)(2)

其中TP为真阳性的样本个数;TN为真阴性的样本个数;FP为假阳性的样本个数;FN为假阴性的样本个数。

另外,基于不同组成特性的PCA和PLS-DA分析所用样本不一致,因此本研究仅在脂肪酸、氨基酸和元素3个组成层面分别进行种属鉴别变量的挖掘,未进行不同组成特性变量的融合与对比分析。

《兰纳克》是一次寻根之旅,是一个民族主义者和小说家表达对本民族命运关切的特有方式,同时它也是一个政治讽喻,以魔幻现实主义的方式呈现了内受经济衰退困扰、外逢强权政府压制的苏格兰社会状况,它更是整个西方工业社会的写照,揭示了现代城市生活各种状况的根源。在这部具有强烈“反乌托邦”色彩的小说中,格雷以讽刺的手法表达了对个人命运的关切和对社会政治经济的不满,批判了整个西方的政治意识形态。

2 结果与分析

2.1 基本组分分析

不同种属肉骨粉的含水率、粗蛋白、粗灰分和粗脂肪含量如表1所示。不同种属肉骨粉的基础特性存在明显差异。肉骨粉样本的含水率相似,其中,鸡肉骨粉的粗蛋白含量较高(<0.05);哺乳动物(牛、羊、猪)肉骨粉与非哺乳动物(鸡)肉骨粉相比,其粗灰分含量显著提高(<0.05),这可能是因为哺乳动物肉骨粉中含有较多的骨成分;不同种属肉骨粉之间粗脂肪含量也存在明显差异(<0.05)。

2.2 元素组成分析

如表1所示,不同种属肉骨粉骨颗粒之间有10种元素(C、N、H、Ca、Na、K、Mg、Zn、Sr、Ba)存在显著性差异(<0.05):C元素在非反刍动物(猪、鸡)肉骨粉骨颗粒中的含量显著高于反刍动物(牛、羊)样本(<0.05),Sr、Ba元素在反刍动物肉骨粉骨颗粒中的含量显著高于非反刍动物样本(<0.05);K、Zn元素鸡肉骨粉骨颗粒中含量显著高(<0.05);与猪肉骨粉骨颗粒相比,Ca、Na元素在鸡肉骨粉骨颗粒中显著低(<0.05);与牛源样本相比,Mg、Sr元素在羊肉骨粉骨颗粒中含量显著高(<0.05),而N和H元素含量显著低(<0.05)。

2.3 脂肪酸组成分析

脂肪酸C4:0、C11:0、C15:1、C24:0、C20:5n3和C24:1n9在不同种属肉骨粉中均未检测到;C14:0、C17:0、C18:0、C18:1n9t的含量在反刍动物(牛、羊)肉骨粉中要高于非反刍动物(猪、鸡)肉骨粉中的含量,而C18:1n9c和C18:2n6c的含量则低于非反刍动物(猪、鸡)肉骨粉中的含量;脂肪酸C13:0、C18:2n6t在反刍动物肉骨粉中检出,在非反刍动物肉骨粉中并未检出;C22:1n9、C20:3n3在非反刍动物肉骨粉中检出,在反刍动物肉骨粉中并未检出;羊肉骨粉中C10:0、C14:1、C17:0、C18:0、C18:2n6t和C18:3n3的含量显著不同于其在牛肉骨粉中的含量(<0.05);C21:0和C22:0在猪肉骨粉中检出,而在鸡肉骨粉中未检出;C18:3n6、C22:2n6和C22:6n3在鸡肉骨粉中检出,而在猪肉骨粉中未检出;C10:0、C18:0和C20:0在猪肉骨粉中的含量显著区高于其在鸡肉骨粉中的含量(<0.05),猪肉骨粉中C18:2n6c的含量显著低于鸡肉骨粉;C18:2n6c在鸡肉骨粉中的含量要显著高于其在猪肉骨粉中的含量(<0.05);多不饱和脂肪酸在反刍动物肉骨粉(牛、羊)中的含量差异显著低于非反刍动物肉骨粉(猪、鸡)(<0.05)。

2.4 游离氨基酸组成分析

分析表1可知,除了游离丝氨酸浓度在反刍动物肉骨粉和非反刍肉骨粉之间存在显著差异(<0.05),其余17种游离氨基酸浓度均无显著性差异(>0.05)。牛羊肉骨粉间不显著差异可能是由于样本量较小导致,因此,本研究主要得到了反刍与非反刍肉骨粉的氨基酸组成差异,并进一步挖掘了反刍与非反刍肉骨粉之间的特异性氨基酸组成变量。

2.5 基于组成信息的不同种属肉骨粉主成分分析

图1a是基于元素组成信息的主成分分析结果。第一、二、三主成分分别占总变异数的32.04%、17.34%和10.12%。猪、鸡肉骨粉样本分布范围较广,且在第一主成分上与牛、羊肉骨粉有较好的区分;牛肉骨粉和羊肉骨粉样本相互重叠且分布较集中;猪肉骨粉和鸡肉骨粉有少量样本重叠,在第二主成分上有较好的区分。这说明在元素组成信息中具有挖掘肉骨粉种属间特异性的潜力。

基于脂肪酸组成信息的主成分分析结果如图1b所示,第一、二、三主成分分别占总变异数的26.33%、9.62%和8.39%。反刍动物(牛、羊)肉骨粉样本和非反刍动物(猪、鸡)肉骨粉样本分别落在第二主成分的正和负方向上,区分明显;猪、鸡肉骨粉样本在第三主成分上有少量重叠,区分较为明显。这说明不同种属肉骨粉的脂肪酸组成信息存在差异,具有挖掘种属特异性的潜力。

基于氨基酸组成信息的主成分分析结果如图1c所示,第一、二、四主成分分别占总变异数的37.24%、17.85%和6.01%。非反刍动物(猪、鸡)肉骨粉样本和反刍动物(牛、羊)肉骨粉样本在第一主成分上有明显的区分;猪、鸡肉骨粉样本分布范围广,在第四主成分上有较好的区分;牛、羊肉骨粉样本之间距离较近,这可能由样本量较少导致。可见,反刍动物肉骨粉(牛、羊)和非反刍动物肉骨粉(猪、鸡)在氨基酸组成信息上存在一定的特异性,该差异可能主要是由于丝氨酸的含量差异引起(<0.05)。

图1 基于不同种属肉骨粉组成信息的主成分分析

2.6 基于组成信息的肉骨粉种属偏最小二乘判别分析

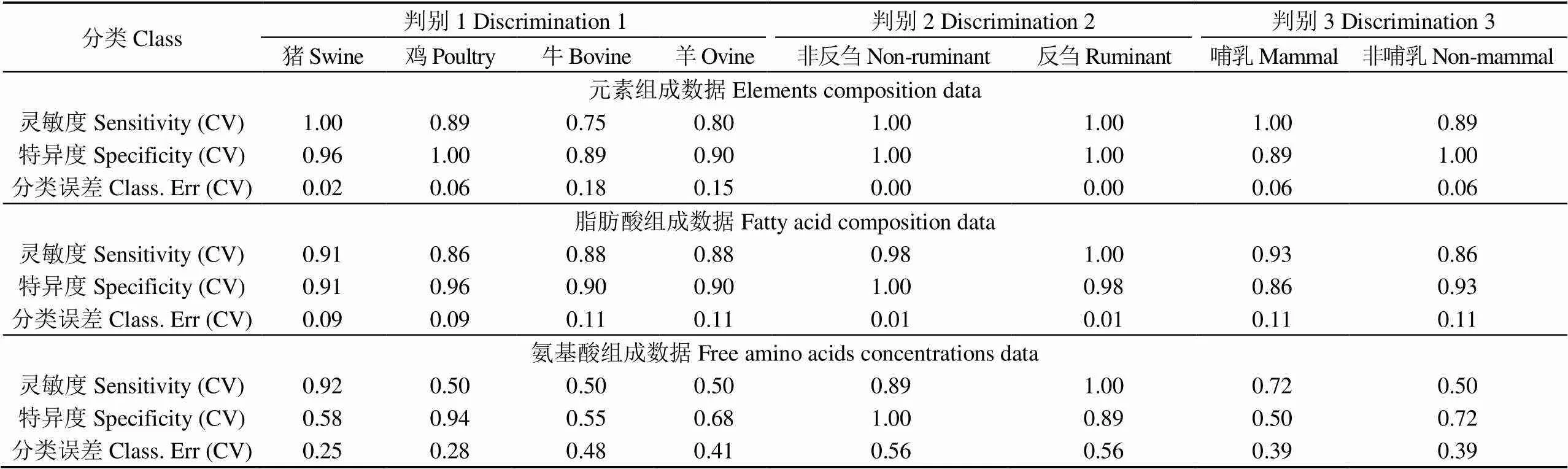

进一步对肉骨粉组成信息进行PLS-DA判别分析,其结果见表2(灵敏度和特异度均大于0.80的判别分析结果被突出显示)。基于脂肪酸组成和元素组成信息的模型在判别1、判别2和判别3中均取得了良好的判别结果;基于氨基酸组成信息可以较好地判别反刍动物肉骨粉和非反刍肉骨粉。这进一步说明了不同种属肉骨粉组分之间存在特异性。

2.7 肉骨粉种属间具有标志性的组成变量挖掘

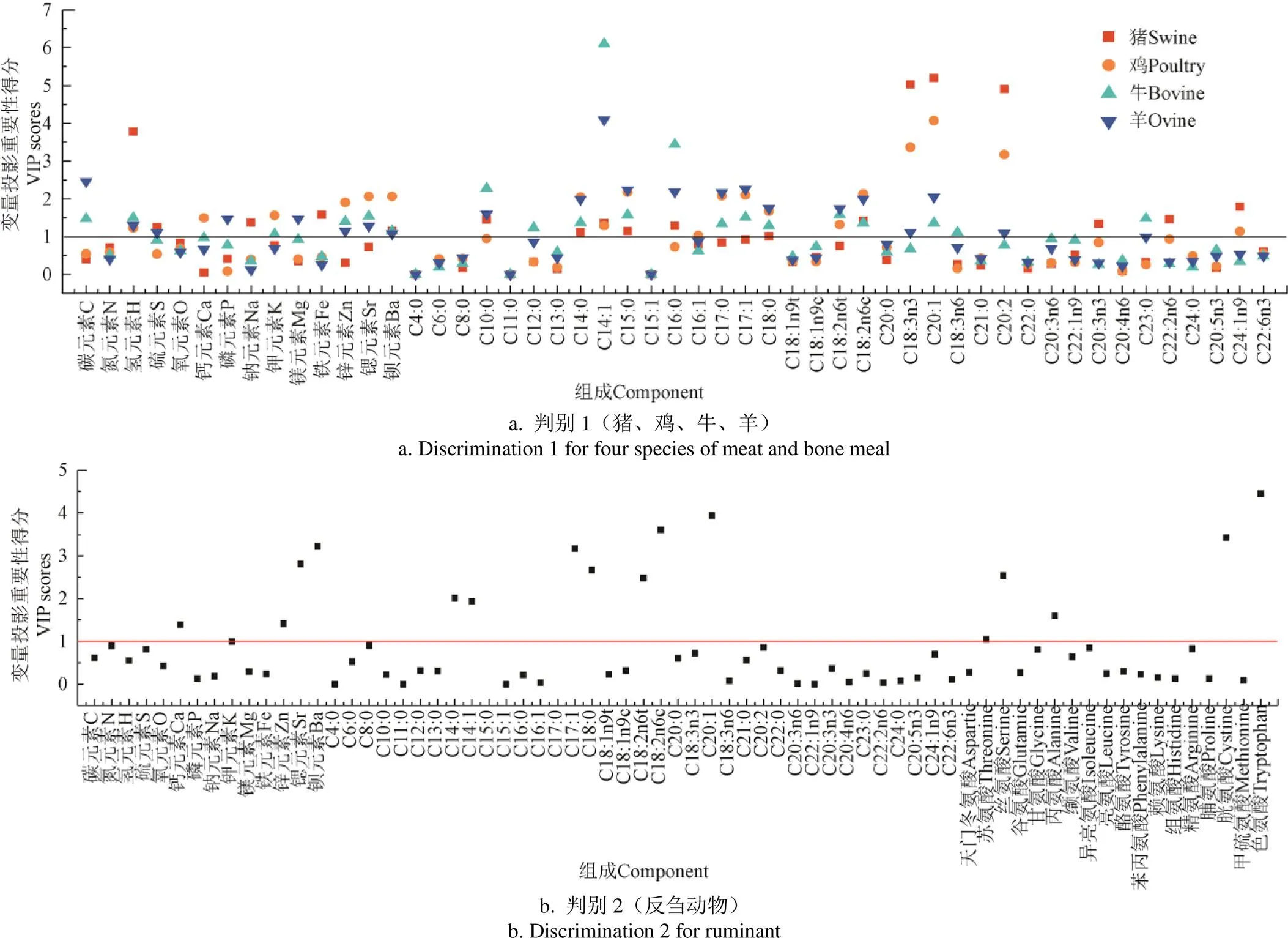

基于PLS-DA和单因素方差分析对不同种属肉骨粉的潜在标志物进行挖掘。3种PLS-DA判别分析的VIP值如图2所示。对于判别1(猪、鸡、牛和羊),VIP值大于1的组成变量数量分别为16个(猪)、18个(鸡)、18个(牛)和18个(羊);判别2(反刍动物和非反刍动物)中VIP值大于1的组成变量数为18个;判别3(哺乳动物和非哺乳动物)中,VIP值大于1的组成变量数为17个。其中同时满足VIP大于1和<0.05的变量数分别为3个(判别1,猪)、5个(判别1,鸡)、6个(判别1,牛)、8个(判别1,羊)、10个(判别2)、6个(判别3)。具体挖掘的不同种属肉骨粉特异性组成变量见表3。

表1 不同种属肉骨粉组成特性差异分析

注:同一变量不同种属平均值标记字母不同,其差异显著(<0.05);nd为未检出;trace表示平均含量低于0.005%。

Note: Different mark letters in same variable show significant difference of different species (<0.05); nd refers to not detected; trace shows the content is lower than 0.005%.

表2 不同种属肉骨粉PLS-DA判别分析

注:CV 为交互验证;Class. Err为分类误差。

Note: CV refers to cross validation; Class. Err refers to classification error.

表3 肉骨粉种属间具有标志性的组成变量

注:含量列参数的单位与表1相同。

Note: units of the parameters in content column are the same as those in Table 1.

3 结 论

研究结果表明,不同种属肉骨粉物料特性在基本组分、元素组成、脂肪酸组成和氨基酸组成上均存在差异。PLS-DA结合单因素方差分析,表明脂肪酸组成和元素组成均可以对不同种属肉骨粉进行判别分析;氨基酸组成可以判别分析反刍和非反刍肉骨粉。进一步挖掘获得了不同种属肉骨粉之间的特异性组成标志变量:

1)猪肉骨粉的特异性组成标志变量为C10:0、C18:0、C18:2n6c;

2)鸡肉骨粉的特异性组成标志变量为Ca、K、Zn、C18:0、C18:2n6c;

3)牛肉骨粉的特异性组成标志变量为Sr、C14:1、C17:0、C17:1、C18:0、C18:2n6t;

4)羊肉骨粉的特异性组成标志变量为H、Mg、Sr、C10:0、C16:0、C17:0、C17:1、C18:0;

5)Sr、Ba、C14:1、C17:0、C15:0、C17:1、C18:0、C18:2n6t、C18:2n6c、丝氨酸可作为反刍和非反刍动物肉骨粉之间的特异性组成标志变量;

6)K、Zn、C18:0、C18:2n6c可作为哺乳和非哺乳动物肉骨粉之间的特异性组成标志变量。

本研究全面地获取了不同组成特性数据,结合化学计量学方法鉴别不同种属肉骨粉的可行性,并建立了系列种属鉴别模型;进一步在不同组成特性层面,对肉骨粉种属鉴别标志性变量进行了挖掘。研究结果可以为基于光谱的肉骨粉种属鉴别机理分析提供数据支持,并可以为肉骨粉的多元工程应用细化至不同种属提供理论基础。

[1]Hendriks W H, Butts C A, Thomas D V, et al. Nutritional quality and variation of meat and bone meal[J]. Asian-Australasian Journal of Animal Sciences, 2002, 15(10): 1507-1516.

[2]Choppe W, Kratzer F H. Methods for evaluating the feeding quality of meat-and-bone meals[J]. Poultry Science, 1963, 42(3): 642-646.

[3]Kratzer F H, Davis P N. The feeding value of meat and bone meal protein[J]. Poultry Science, 1959, 38(6): 1389-1393.

[4]Nathanson N, Wilesmith J W, Griot Christian. Bovine spongiform encephalopathy (BSE): causes and consequences of a common source epidemic[J]. American Journal of Epidemiology, 1997, 145: 959-969.

[5]van Raamsdonk L W D, Prins T W, Meijer N, et al. Bridging legal requirements and analytical methods: a review of monitoring opportunities of animal proteins in feed[J]. Food Additives & Contaminants: Part A, 2019, 36(1): 46-73.

[6]Cascarosa , Gea G, Arauzo J. Thermochemical processing of meat and bone meal[J]. Renewable and Sustainable Energy Reviews, 2012, 16(1): 942-957.

[7]Beck J, Brandenstein J, Unterberger S, et al. Effects of sewage sludge and meat and bone meal Co-combustion on SCR catalysts[J]. Applied Catalysis B: Environmental, 2004, 49(1): 15-25.

[8]Mouchet F, Cren S, Cunienq C, et al. Assessment of lead ecotoxicity in water using the amphibian larvae (Xenopus laevis) and preliminary study of its immobilization in meat and bone meal combustion residues[J]. BioMetals, 2006, 20(2): 113.

[9]Lee J, Won M, Song K. Physical properties and antimicrobial activities of porcine meat and bone meal protein films containing coriander oil[J]. LWT - Food Science and Technology, 2015, 63(1): 700-705.

[10]Essandoh M, Garcia R A, Nieman C M, et al. Influence of methylation on the effectiveness of meat and bone meal protein as a bioflocculant[J]. Food and Bioproducts Processing, 2020, 122: 55-61.

[11]Piazza G J, Garcia R A. Meat & bone meal extract and gelatin as renewable flocculants[J]. Bioresource Technology, 2010, 101(2): 781-787.

[12]Vamvuka D, Papas M, Alloimonos N, et al. Evaluation of meat and bone meal as a secondary fuel with olive by-products in a fluidized bed unit. performance and environmental impact of ashes[J]. Energy & Fuels, 2017, 31(7): 7214-7222.

[13]Ariyaratne W K H, Malagalage A, Melaaen M C, et al. CFD modelling of meat and bone meal combustion in a cement rotary kiln – Investigation of fuel particle size and fuel feeding position impacts[J]. Chemical Engineering Science, 2015, 123: 596-608.

[14]Soni C G, Wang Z, Dalai A K, et al. Hydrogen production via gasification of meat and bone meal in two-stage fixed bed reactor system[J]. Fuel, 2009, 88(5): 920-925.

[15]Staroń P, Kowalski Z, Staroń A, et al. Thermal conversion of granules from feathers, meat and bone meal and poultry litter to ash with fertilizing properties[J]. Agricultural and Food Science, 2017, 26(3): 173-180.

[16]Liu X, Selonen V, Steffen K, et al. Meat and bone meal as a novel biostimulation agent in hydrocarbon contaminated soils[J]. Chemosphere, 2019, 225: 574-578.

[17]Al-Masri M. Productive performance of broiler chicks fed diets containing irradiated meat-bone meal[J]. Bioresource Technology, 2003, 90: 317-322.

[18]Zanu H K, Keerqin C, Kheravii S K, et al. Influence of meat and bone meal, phytase, and antibiotics on broiler chickens challenged with subclinical necrotic enteritis: 1. growth performance, intestinal pH, apparent ileal digestibility, cecal microbiota, and tibial mineralization[J]. Poultry Science, 2020, 99(3): 1540-1550.

[19]Wang S, Yuan H, Wang Y, et al. Transesterification of vegetable oil on low cost and efficient meat and bone meal biochar catalysts[J]. Energy Conversion and Management, 2017, 150: 214-221.

[20]Wu G, Healy M G, Zhan X. Effect of the solid content on anaerobic digestion of meat and bone meal[J]. Bioresource Technology, 2009, 100(19): 4326-4331.

[21]Andriamanohiarisoamanana F J, Saikawa A, Kan T, et al. Semi-continuous anaerobic co-digestion of dairy manure, meat and bone meal and crude glycerol: Process performance and digestate valorization[J]. Renewable Energy, 2018, 128: 1-8.

[22]Wang M, Liu Y, Yao Y, et al. Comparative evaluation of bone chars derived from bovine parts: Physicochemical properties and copper sorption behavior[J]. Science of The Total Environment, 2020, 700: 1-6.

[23]Makara A, Kowalski Z, Saeid A. Treatment of wastewater from production of meat-bone meal[J]. Open Chemistry, 2015, 13: 1275-1285.

[24]Coutand M, Deydier E, Cyr M, et al. Evaluation of laboratory and industrial meat and bone meal combustion residue as cadmium immobilizing material for remediation of polluted aqueous solutions: “Chemical and ecotoxicological studies”[J]. Journal of Hazardous Materials, 2009, 166(2): 945-953.

[25]Leng L, Zhang J, Xu S, et al. Meat & bone meal (MBM) incineration ash for phosphate removal from wastewater and afterward phosphorus recovery[J]. Journal of Cleaner Production, 2019, 238: 117960.

[26]Garcia R, Piazza G. Application of the elusieve process to the classification of meat and bone meal particles[J]. Applied Engineering in Agriculture, 2015, 31: 165-170.

[27]Han Y, Wang X, Liu Y, et al. A novel FTIR discrimination based on genomic DNA for species-specific analysis of meat and bone meal[J]. Food Chemistry, 2019, 294: 526-532.

[28]Gao F, Xu L, Zhang Y, et al. Analytical Raman spectroscopic study for discriminant analysis of different animal-derived feedstuff: Understanding the high correlation between Raman spectroscopy and lipid characteristics[J]. Food Chemistry, 2018, 240: 989-996.

[29]Gao F, Zhou S, Han L, et al. A novel FT-IR spectroscopic method based on lipid characteristics for qualitative and quantitative analysis of animal-derived feedstuff adulterated with ruminant ingredients[J]. Food Chemistry, 2017, 237: 342-349.

[30]Wang M, Han L, Yang Z, et al. Species discrimination of terrestrial processed animal proteins by laser-induced breakdown spectroscopy (LIBS) based on elemental characteristics[J]. Biotechnologie, Agronomie, Société et Environnement, 2019, 23(3): 137-146.

[31]Buckley M, Penkman K E H, Wess T J, et al. Protein and mineral characterisation of rendered meat and bone meal[J]. Food Chemistry, 2012, 134(3): 1267-1278.

[32]Parsons C M, Castanon F, Han Y. Protein and amino acid quality of meat and bone meal[J]. Poultry Science, 1997, 76(2): 361-368.

[33]Hendriks W H, Cottam Y H, Morel P C H, et al. Source of the variation in meat and bone meal nutritional quality[J]. Asian-Australasian Journal of Animal Sciences, 2004, 17(1): 94-101.

[34]Garcia R A, Rosentrater K A. Concentration of key elements in North American meat & bone meal[J]. Biomass and Bioenergy, 2008, 32(9): 887-891.

[35]Ockerman H, Hansen C. Animal By-product Processing and Utilization[M]. Boca Raton: CRC Press, 1999.

[36]Pu Q, Han L, Liu X. A new approach for species discrimination of different processed animal proteins based on fat characteristics[J]. European Journal of Lipid Science & Technology, 2016, 118(4): 576-583.

[37]殷勇,赵玉珍,于慧春. 基于多种变量分析方法鉴别食醋种类电子鼻信号特征筛选[J]. 农业工程学报,2018,34(15):290-297. Yin Yong, Zhao Yuzhen, Yu Huichun. Feature selection of electronic nose signal for vinegar discrimination based on multivariable analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(15): 290-297. (in Chinese with English abstract)

[38]滑金杰,王华杰,王近近,等. 采用PLS-DA分析毛火方式对工夫红茶品质的影响[J]. 农业工程学报,2020,36(8):260-270. Hua Jinjie, Wang Huajie, Wang Jinjin, et al. Influences of first-drying methods on the quality of Congou black tea using partial least squares-discrimination analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(8): 260-270. (in Chinese with English abstract)

[39]刘贤,徐凌芝,高冰,等. 红外光谱的陆生动物油脂中反刍动物成分鉴别分析[J]. 光谱学与光谱分析,2019,39(10):3189-3192. Liu Xian, Xu Lingzhi, Gao Bing, et al. Discriminant analysis of ruminant constituents in terrestrial fat and oil by infrared spectroscopy[J]. Spectroscopy and Spectral Analysis, 2019, 39(10): 3189-3192. (in Chinese with English abstract)

[40]Liu H, Guo X, Zhao Q, et al. Lipidomics analysis for identifying the geographical origin and lactation stage of goat milk[J]. Food Chemistry, 2019, 309: 1- 6.

Markers mining for species discrimination based on component characteristics of meat and bone meal

Gao Bing, Wang Mengyan, Yao Yumei, Gao Fei, Han Lujia, Liu Xian※

(,,100083,)

This study aims to comprehensively characterize the composition of meat and bone meal, and further to identify the specific variables of various species using a data mining method. Based on the component characteristics data, a comprehensive comparison and markers mining study were carried out for the meat and bone meal that produced by various species. 166 samples of meat and bone meal were produced from various species (55 swine, 43 poultry, 36 bovine, and 32 ovine) in different factories of China. Composition characteristics in the samples of meat and bone meal were detected from four aspects, including the proximate component, element, fatty acid, and amino acid composition. The results of proximate component show that there was a complex variation in the samples of meat and bone meal, leading to the difference in four species was not considered statistically significance. An one-way Anova variance analysis was conducted for the composition data of element, fatty acid, and amino acid. 69 component variables were compared, incuding 14 variables from element composition, 37 variables from fatty acid composition, 18 variables from amino acid composition, in the meat and bone meal from different species. Consequently, there were significant differences among species (<0.05) for 31 component variables, including 10 variables from element composition, 20 variables from fatty acid composition, 1 variable from amino acid composition. It infers that the component characteristics of meat and bone meal varied significantly in different species, particularly on the specific component variables. A Principal Component Analysis (PCA) combined with the Partial Least Square Discrimination Analysis (PLS-DA) was used to explore the species specificity of meat and bone meal. The results showed that the composition variables of element and fatty acid can serve as markers to idnetify the swine, poultry, bovine, as well as ovine meat and bone meal. The composition variables of amino acid were mainly marker sources of ruminant and non-ruminant meat and bone meal. Comprehensively characterization using the PLS-DA and one-way Anova variance analysis demonstrated that, taking the VIP value greater than 1, while< 0.05 as the united indicator, the specific variables were achieved in the meat and bone meal for the species of: 1) swine were C10:0, C18:0 and C18:2n6c, 2) poultry were Ca, K, Zn, C18:0 and C18:2n6c, 3) bovine were Sr, C14:1, C17:0, C17:1, C18:0 and C18:2n6t, 4) ovine were H, Mg, Sr, C10:0, C16:0, C17:0, C17:1 and C18:0, 5) ruminant and non-ruminant were Sr, Ba, C14:1, C17:0, C15:0, C17:1, C18:0, C18:2n6t, C18:2n6c and serine, and 6) mammal and non-mammal were K, Zn, C18:0 and C18:2n6c. These selected specific variables can provide: a sound theoretical basis for the multi-application of meat and bone meal from different species. The finding can also offer sinificant data support for the mechanism analysis and further application of meat and bone meal, particularly on the species identification method.

Principal Component Analysis; fatty acid; amino acid; meat and bone meal; different species; component characteristics; comparison analysis; markers mining

高冰,王梦妍,姚玉梅,等. 基于组成特性的肉骨粉种属鉴别标志性变量挖掘[J]. 农业工程学报,2020,36(18):275-282.doi:10.11975/j.issn.1002-6819.2020.18.032 http://www.tcsae.org

Gao Bing, Wang Mengyan, Yao Yumei, et al. Markers mining for species discrimination based on component characteristics of meat and bone meal[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(18): 275-282. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.18.032 http://www.tcsae.org

2020-05-26

2020-09-10

国家重点研发计划项目(2017YFE0115400)和现代农业(奶牛)产业技术体系建设专项资金项目(CARS-36)

高冰,博士生,主要从事生物质资源与利用研究。Email:gaobing@cau.edu.cn

刘贤,副教授,博士生导师,主要从事生物质资源与利用研究。Email:lx@cau.edu.cn

10.11975/j.issn.1002-6819.2020.18.032

X713;S879.9

A

1002-6819(2020)-18-0275-08