Anomalous strain effect in heteroepitaxial SrRuO3 films on(111)SrTiO3 substrates

Zhenzhen Wang(王珍珍) Weiheng Qi(戚炜恒) Jiachang Bi(毕佳畅) Xinyan Li(李欣岩) Yu Chen(陈雨)Fang Yang(杨芳) Yanwei Cao(曹彦伟) Lin Gu(谷林) Qinghua Zhang(张庆华) Huanhua Wang(王焕华)Jiandi Zhang(张坚地) Jiandong Guo(郭建东) and Xiaoran Liu(刘笑然)

1Beijing National Laboratory for Condensed Matter Physics and Institute of Physics,Chinese Academy of Sciences,Beijing 100190,China

2School of Physical Sciences,University of Chinese Academy of Sciences,Beijing 100049,China

3Institute of High Energy Physics,Chinese Academy of Sciences,Beijing 100049,China

4Ningbo Institute of Materials Technology and Engineering,Chinese Academy of Sciences,Ningbo 315201,China

5Beijing National Center for Electron Microscopy and Laboratory of Advanced Materials,Department of Materials Science and Engineering,Tsinghua University,Beijing 100084,China

6Songshan Lake Materials Laboratory,Dongguan 523808,China

Keywords: perovskite SrRuO3,(111)-oriented thin films,heteroepitaxial strain,octahedral tilt and rotation

1. Introduction

Heteroepitaxy is a powerful avenue for exploring and tailoring novel properties of transition metal oxides with synergistic couplings of various degrees of freedom.[1–5]The asymmetries in lattice, charge, orbital and spin degrees of freedom at the interface between the film and substrate lead to the emergence of latent or hidden phenomena that are inaccessible in bulk materials.[1,6]Heteroepitaxial engineering has been widely utilized in the material families of perovskite oxides(chemical formula ABO3)whose structure is characteristic of the three-dimensional network of corner-sharing BO6octahedra. While the ideal symmetry of ABO3is cubic, adjacent BO6octahedra can rotate and the overall symmetry is lowered as a result of the mismatches between A and B cations,which is determined by the so-called‘tolerance factor’.[7,8]

Scenarios of coupling between perovskite oxide thin films and substrates have been extensively explored for(001)-oriented epitaxy.[9–15]In this situation,since those two orthogonal directions of(001)biaxial strain coincide with the principal axes of the pseudo-cubic unit cell, it has been generally rationalized that the effect of a compressive (tensile) strain would increase (decrease) the out-of-plane lattice parameter,and further enhance(suppress)the octahedral rotations around the out-of-plane axis.[15–20]However,with recent advances in the fabrication of high-quality perovskite oxide epitaxial films along other crystallographic orientations, much less knowledge about the strain effect has been revealed thus far compared with the (001) case. Especially for the case of (111)heteroepitaxy,none of the three tilting axes are parallel or perpendicular to the strain plane,such that the paradigm described above for(001)strain is no longer applicable. Whether or not the epitaxial strain is still preserved, and how it would affect the physical properties of films,remains unclear.[21–24]

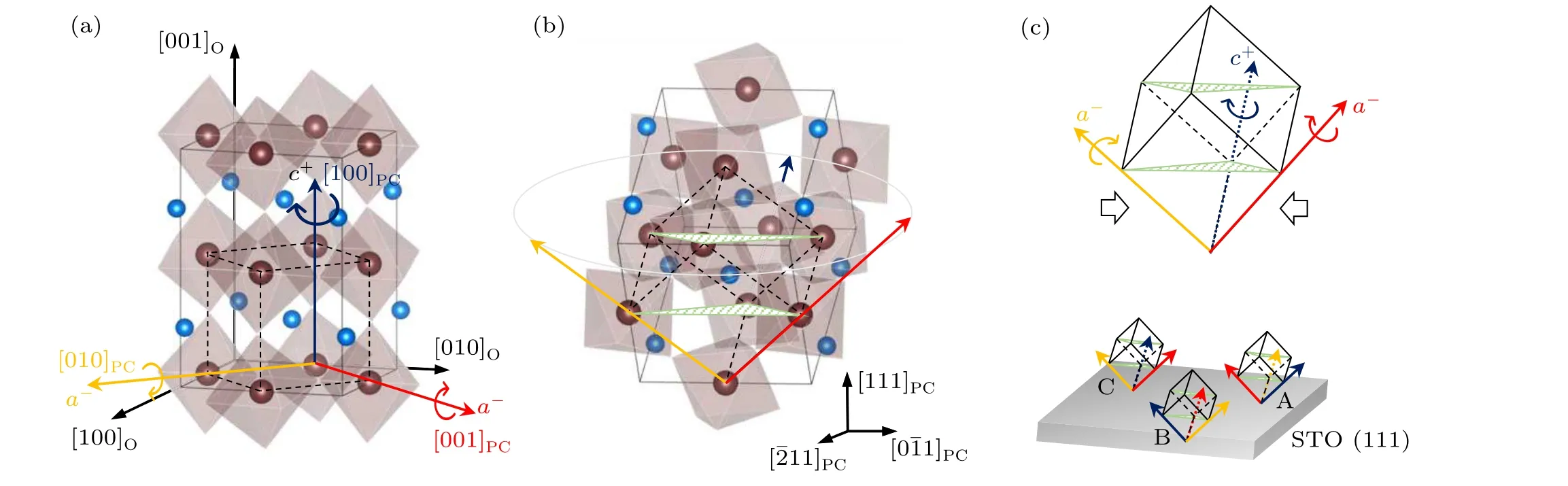

In this work, to address these issues we focus on the 4d transition metal oxide SrRuO3(SRO). As one of the most representative perovskite oxides, heteroepitaxial thin films of(001)-oriented SRO have attracted tremendous research interest for decades.[25]The conventional unit cell of bulk SRO is illustrated in Fig.1(a). SRO possesses an orthorhombicPbnmcrystal structure with the lattice parametersa= 5.5670 ˚A,b= 5.5304 ˚A, andc= 7.8446 ˚A.[25]The RuO6octahedra rotate in the same manner (in-phase) along the pseudo-cubic

[010]PCand [001]PCdirections, and in the opposite manner(anti-phase) along the pseudo-cubic [100]PCdirection, leading to an‘a−a−c+’tilting pattern in Glazer notation[26]and a pseudo-cubic lattice constant of∼3.93 ˚A.High-quality SRO epitaxial thin films have been fabricated on [111]-oriented SrTiO3(STO)substrates. X-ray diffraction(XRD)and reciprocal space mapping (RSM) data demonstrate that the SRO thin film is compressively strained on the substrate with complete coherency. Nevertheless, it is surprising that the outof-plane lattice parameter is rarely varied, at odds with the conventional paradigm. Scanning transmission electron microscopy (STEM) images confirm the coherency and sharpness of the film–substrate interface and shed light on the suppression of thec+tilting inside the film. Synchrotron-based XRD on a series of half-ordering reflections clearly demonstrates the establishment of three equivalent domain structures of SRO on the (111)-oriented STO substrate, each of which hosts thea−a−c+tilting pattern with significant suppression of thec+tilting angle compared with bulk SRO.These experimental findings highlight a peculiar paradigm for the accommodation of(111)strain,and pave a new route towards turning the properties of oxide thin films via strain engineering along other crystallographic directions.

Fig.1. (a)Schematic illustration of the orthorhombic(O)conventional unit cell and the pseudo-cubic(PC)unit cell of SRO.The three axes of RuO6 tilting are along the pseudocubic〈100〉directions.(b)Transformation of the structure in the case of a(111)PC epitaxial relationship.The(111)planes are highlighted using shadowed green lines. (c)SRO under(111)compressive strain. Three equivalent domain structures(A,B,and C)can be epitaxially stabilized on the STO(111)surface.

2. Methods

The general relationship between (001)- and (111)-oriented epitaxial SRO thin films is illustrated in Figs. 1(a)and 1(b).High-quality SRO thin films were fabricated on STO(111)substrates by means of pulsed laser deposition equipped with reflection high-energy electron diffraction. The films were deposited at a substrate temperature of∼730◦C under an oxygen partial pressure of∼10 Pa. A ceramic SRO target with the proper chemical stoichiometry was ablated by a KrF excimer laser at a pulse frequency of 2 Hz(λ=248 nm,laser fluence∼2 J·cm−2). After deposition, the films were annealed at the growth condition for 10 min and cooled down to room temperature. XRD and RSM data were recorded using a Rigaku SmartLab diffractometer. All the indices mentioned in this work are defined in cubic(or pseudo-cubic)notation unless otherwise stated. High-resolution cross-sectional STEM images were taken in the high-angle annular dark-field(HAADF) mode. The sample was cut and projected on the(11¯2)PCplane. Synchrotron-based XRD experiments were performed at beamline 1W1A of the Beijing Synchrotron Radiation Facility. The photon energy was fixed at 8.05 keV during the measurements. Alignment and scans were recorded using the reciprocal lattice unit(r.l.u.) of the STO substrate.

3. Results and discussion

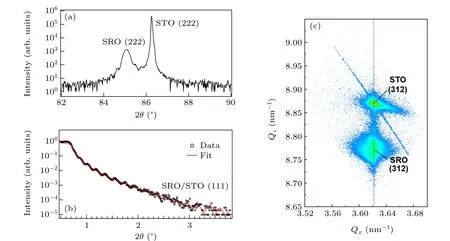

The XRD 2θ–ωsymmetric scans along the{111}planes of SRO film exhibit sharp (222) peaks on the left side of the STO (222) reflection, as shown in Fig. 2(a). The calculated spacing of the{111}planes isd111∼2.27 ˚A, practically the same as that of bulk SRO.[27]The film thickness is∼40 nm,as demonstrated from the x-ray reflectivity scans with fitting(Fig.2(b)),which is consistent with the counting of the pulse numbers during the deposition. Figure 2(c) shows the RSM scans around the STO(312)reflection in an attempt to reveal the in-plane lattice constant and status of the strain of films.As indicated by the black vertical line,it is surprising that the∼40 nm thick SRO film still has the same in-plane componentQxas the STO substrate,corroborating that the SRO film is fully strained to the substrate. The measuredQzvalue of the SRO film is∼8.78 nm−1, corresponding to an out-of-plane spacing of∼2.27 ˚A, in good agreement with the value extracted from XRD symmetric scans. These data immediately challenge the conventional picture of strain accommodation,

where a compressive strain would stretch the out-of-plane lattice spacing. The combined results of XRD and RSM suggest an anomalous heteroepitaxial strain effect in 40 nm thick SRO on a STO(111)substrate.

Fig.2. (a)XRD 2θ–ω scans and(b)x-ray reflectivity(XRR)of SRO film grown on a STO(111)substrate. The thickness of the SRO/STO(111)film is ∼40 nm according to the XRR fitting. (c)Reciprocal space mapping scans near the STO(312)reflection.

To further characterize the tilting pattern of RuO6octahedra and to obtain real-space microscopic information about the film structure,we performed atomic-resolution aberrationcorrected STEM imaging on the (111) SRO sample. Figure 3(a) shows the HAADF-STEM image obtained with the electron beams incident along the [11¯2] direction, which clearly demonstrates the high quality and uniformity of our SRO film with full coherency. Note that only the Sr, Ru and Ti atoms are visible in the HAADF mode as the intensity of atoms is proportional toZ2(Zbeing the atomic number). In order to reach an accurate estimation about the positions of atoms,the STEM image was replotted using CalAtom software.[28]Figure 3(b) shows a representative image of the resultant mapping on a zoomed area as outlined by the red rectangle in Fig.3(a). The corresponding schematic structure of bulk SRO(space groupPbnm)is displayed in Fig.3(c)projected along the [11¯2] direction, which is consistent with the STEM images. The right pattern of Fig.3(c)shows the ideal tilt of the Sr sublattice along the[111]direction in bulk SRO,indicating that the structural characteristics of orthorhombic SRO possessing thea−a−c+rotation pattern can be ascribed to the tilting of the Sr sublattice. Accordingly,thec+octahedral tilt is indicated as the relative Sr–Sr displacement(δSr),as depicted in Fig.3(b). We carried out quantitative analyses onδSrby extracting their values from the HAADF images along the [111] direction, as shown in Fig. 3(d). Note that the data for each unit cell were obtained by statistically averaging over 10 adjacent rows. TheδSron the substrate side is practically zero,which agrees well with the cubic symmetry of STO(i.e.,no tilt). On the side of the SRO film,the expected value ofδSrin its bulk due toc+octahedral tilt is marked by two dotted lines. As seen,while there is a finite magnitude of tilt in the Sr sublattice,it is much smaller than the theoretical value. These analyses provide strong evidence for the significant suppression ofc+rotation in our SRO film under compressive (111)strain.

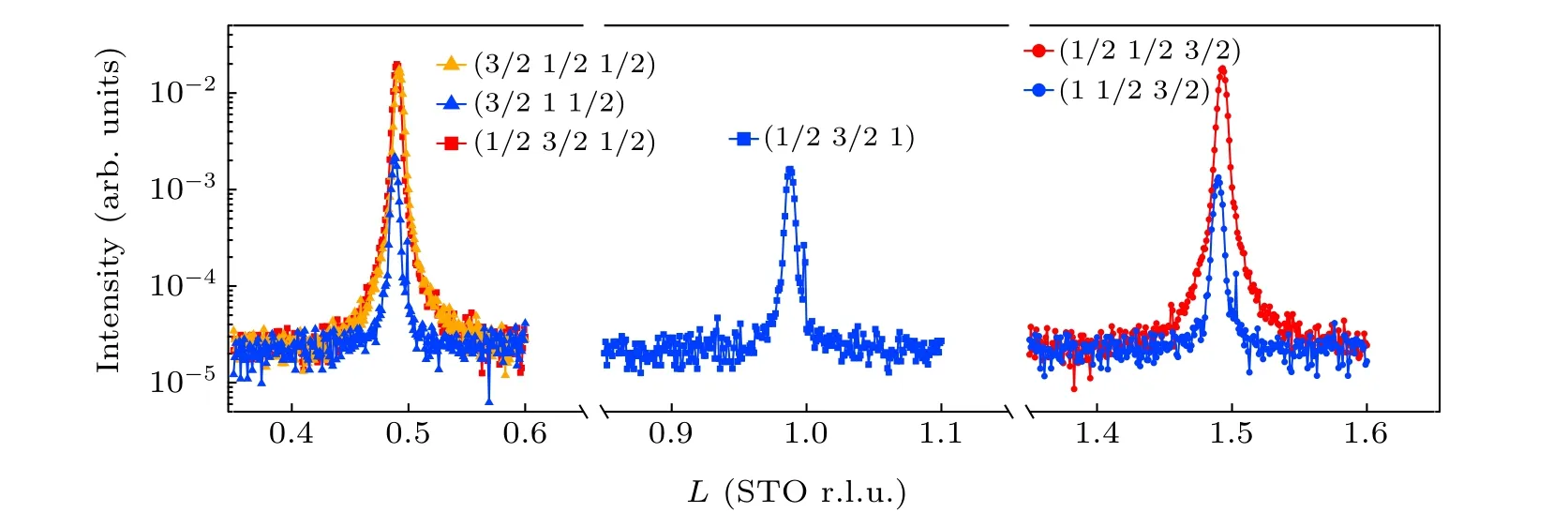

More comprehensive investigations about the tilting pattern of RuO6octahedra in our (111) compressively strained SRO thin films were carried out by probing a series of half-order Bragg reflections using synchrotron-based XRD. Specifically, for SRO with thea−a−c+tilting pattern,{odd/2 odd/2 odd/2}-type reflections (odd refers to an odd integer) withk/=l(h/=l) are produced due to anti-phase tilting around thea(b) rotation axis; whereas{odd/2 odd/2 even/2}-type reflections(even refers to an even integer)withh/=kare produced due to in-phase tilting around thec-axis.[26]This is indeed demonstrated through the observations of the (1/2 3/2 1/2), (3/2 1/2 1/2), and (1/2 3/2 1)reflections, as shown in Fig. 4. However, it is striking that other reflections with indices of{even/2 odd/2 odd/2}and{odd/2 even/2 odd/2}, for example the (1 1/2 3/2) and (3/2 1 1/2) peaks, are also present, indicating the existence of inphase tilting around theaandbrotation axes as well.In particular,it is noteworthy that the intensities of these peaks,which are in principle proportional to the square of the corresponding tilting angles,are practically the same for the three half-order reflections containing one even index. Similarly, those three‘odd–odd–odd’style half-order peaks also exhibit a very close magnitude of intensities. These phenomena are plausibly interpreted as a result of hexagonal symmetry of the STO(111)surface, which triggers the formation of three equivalent domain structures in the SRO epitaxial thin films,depending on the specific selection of the in-phase tilting axis out of the three〈100〉directions.

Another point worth noting is that, based on the relationships between the intensities of the half-order reflections and the tilting angles in thea−a−c+tilting pattern,I(c+) ∝(hik −kih)γ2;I(a−) ∝((kil −lik)α+(hil −lih)α+(hik −kih)γ)2.[26]As a result,the intensity of (1/2 3/2 1) is proportional toγ2while the intensity of (1/2 3/2 1/2) is proportional to (α −γ)2. For bulk SRO with an anti-phase tilting angleα ∼9.9◦and an in-phase tilting angleγ ∼10.2◦,the intensity of(1/2 3/2 1)is expected about three orders of magnitude higher than that of (1/2 3/2 1/2). However, as seen in Fig. 4, the intensity of (1/2 3/2 1)is even lower than that of (1/2 3/2 1/2) for the SRO thin film on the (111) STO substrate, indicating that the degree of the in-phase tilting angle is significantly suppressed. These results reveal an intriguing paradigm that the effect of biaxial strain in the(111)plane is accommodated via the modification of a peculiar octahedral tilting, rather than the conventional way of stretching or compressing the out-of-plane spacing as typically seen in the(001)situation.

Fig. 3. (a) High-resolution high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image of SRO film. The HAADF-STEM images were obtained along the [11¯2] zone axis. (b) An example of the replotted STEM image using CalAtom software. (c)Schematic diagrams of orthorhombic bulk SRO(space group Pbnm). The tilt of the individual Sr sublattice is shown on the right of(c). (d)The plot of experimentally measured δSr from the substrate to the surface of the SRO film. The error bars represent standard deviation.

Fig.4. Synchrotron-based XRD HKL-coupled scans on a series of half-ordering reflections of the SRO epitaxial film grown on(111)STO substrate.The measurements were taken at 300 K with an incident photon energy of 8.05 keV (λ =1.5438 ˚A). Data are plotted in STO r.l.u. such that the peaks of the film deviate slightly from the exact half-ordering indices.

4. Conclusion

In summary,we have investigated the effect of(111)heteroepitaxial strain on high-quality SRO thin films on STO(111) substrates. We discovered an anomalous scenario of film–substrate coupling, where the compressive strain is accommodated not via stretching of the out-of-plane lattice spacing as expected in the conventional scenario but via the significant suppression of the degree of a peculiar octahedral rotation. These findings can potentially open new avenues for changing the physical properties of films via strain engineering.

Acknowledgments

Project supported by the National Key Research and Development Program of China(Grant No.2017YFA0303600),the National Natural Science Foundation of China (Grant No. 11974409), and the Strategic Priority Research Program (B) of the Chinese Academy of Sciences (Grant No.XDB33000000).

- Chinese Physics B的其它文章

- Editorial:Celebrating the 30 Wonderful Year Journey of Chinese Physics B

- Attosecond spectroscopy for filming the ultrafast movies of atoms,molecules and solids

- Advances of phononics in 20122022

- A sport and a pastime: Model design and computation in quantum many-body systems

- Molecular beam epitaxy growth of quantum devices

- Single-molecular methodologies for the physical biology of protein machines