Prediction of residual tensile strength of glass fiber reinforced polymer bars in harsh alkaline concrete environment using fuzzy metaheuristic models

Mudssir Iqbl ,Khlid Elbz ,Dxu Zhng ,Lili Hu Fzl E.Jll

a State Key Laboratory of Ocean Engineering, Shanghai Key Laboratory for Digital Maintenance of Buildings and Infrastructure, School of Naval Architecture,Ocean & Civil Engineering, Shanghai Jiao Tong University, Shanghai 200240, China

b Department of Civil Engineering, University of Engineering and Technology Peshawar, Pakistan

c MOE Key Laboratory of Intelligent Manufacturing Technology, Department of Civil and Environmental Engineering, College of Engineering, Shantou University, Shantou, Guangdong 515063, China

d Department of Civil Engineering, Higher Future Institute of Engineering and Technology, Mansoura, Egypt

Keywords:Gfrp Seawater sea sand concrete Durability Metaheuristic Anfis-pso,anfis-ga ANFIS-SVM

ABSTRACT The long-term durability of glass fiber reinforced polymer (GFRP) bars in harsh alkaline environments is of great importance in engineering,which is reflected by the environmental reduction factor in various structural codes.The calculation of this factor requires robust models to predict the residual tensile strength of GFRP bars.Therefore,three robust metaheuristic algorithms,namely particle swarm optimization (PSO),genetic algorithm (GA),and support vector machine (SVM),were deployed in this study for achieving the best hyperparameters in the adaptive neuro-fuzzy inference system (ANFIS) in order to obtain more accurate prediction model.Various optimized models were developed to predict the tensile strength retention (TSR) of degraded GFRP rebars in typical alkaline environments (e.g.,seawater sea sand concrete (SWSSC) environment in this study).The study also proposed more reliable model to predict the TSR of GFRP bars exposed to alkaline environmental conditions under accelerating laboratory aging.A total number of 715 experimental laboratory samples were collected in a form of extensive database to be trained.K-fold cross-validation was used to assess the reliability of the developed models by dividing the dataset into five equal folds.In order to analyze the efficiency of the metaheuristic algorithms,multiple statistical tests were performed.It was concluded that the ANFIS-SVM-based model is robust and accurate in predicting the TSR of conditioned GFRP bars.In the meantime,the ANFIS-PSO model also yielded reasonable results concerning the prediction of the tensile strength of GFRP bars in alkaline concrete environment.The sensitivity analysis revealed GFRP bar size,volume fraction of fibers,and pH of solution were the most influential parameters of TSR.

1.Introduction

Steel-reinforced concrete structures deteriorate mainly due to steel corrosion,which leads to significant economic damage resulting from frequent maintenance and repairs [1].The problem of steel corrosion is intensified in off-shore structures such as oil drilling platforms,floating docks,and seaports [2,3].Glass fiberreinforced polymer (GFRP) bars are widely used in civil engineering structures,as these bars exhibit good fatigue behavior,high strength-to-weight ratio,great corrosion resistance and convenient constructions [4,5].When the GFRP bars are exposed to severe environmental conditions,such as marine and alkaline environments,their long term behevior is of significant concern.

The United Nations reported that the global population could reach approximately 9.7 billion by 2050,thus posing a huge impact on the development of infrastructure and the bulk use of construction materials.Therefore,the mounting demand for infrastructure has headed towards seawater and sea sand concrete (SWSSC) as an alternative to fresh water and natural aggregates [6,7].The actual environment of moist SWSSC concrete is alkaline in nature,and its pH ranges from 10.5 to 13 [8,9].Among various exposure environments,a moist alkaline environment is considered one of the most aggressive factors in the degradation of mechanical properties of GFRP bars [10,11].The free hydroxyl (OH-) ions that diffuse through concrete pore solution tend to attack the GFRP bars.As a result,the surrounding moist alkaline environment of the GFRP bars aggravates hydrolysis,leaching,and etching that causes deterioration of the mechanical properties of the GFRP bars [12,13].

Previous researchers reported that the mechanical properties such as tensile strength [14],bond strength [15],and inter-laminar shear strength [16] of GFRP bars degrade in a variety of harsh environments [17,16,18],which are important durability metrics of the GFRP.Additionally,the degradation of GFRP rebars is a long-term phenomenon;therefore,accelerating aging techniques are used to initially assess their short-term performance [14,19].However,for measuring the long-term performance,accelerating aging results can be obtained by using the eminent Arrhenius relation [20,18],Huang and Aboutaha model [21,22] and Dejke and Tepfers [ 23,24 ]approach.The environmental degradation of tensile strength of GFRP during its long-term exposure is given in the form of an environmental reduction factor (CE),in different international codes such as CSA-S806 [25],CNR [26],ACI [27],NS3473 [28] and JSCE[29].Previously,the performance of tensile strength was investigated inside an alkaline environment using the accelerating aging method,which requires extensive testing in the laboratory under control conditions for longer duration (up to six months)[13,14,30–38].Micelli et al.[34] investigated GFRP coupons after conditioning in alkaline solution having pH=12.6 for 718 h and found a maximum tensile strength loss of 18%.Moreover,Micelli,Aiello [35] confirmed E-glass fibers to be more sensitive to alkaline environment as compared to aramid and carbon fibers.Benmokrane et al.[33] investigated the effect of different bar sizes on moisture absorption and residual tensile strength.It was concluded from those studies that degradation of tensile strength of GFRP bars depends on several factors,which include pH of conditioning environment [14,12],exposure temperature [10],sustained stress level [39,40],moisture content of surrounding concrete [20,30],type of resin [17,32],bar diameter [33,36] and conditioning duration [31].Iqbal et al.[41] recently found that,for GFRP bars with a specific type of glass fibers and resin matrix,the tensile strength retention (TSR) is a function of six main production parameters,including;diameter of the bar (db),the volume fraction of fibers (Vf),conditioning parameters,pH of the solution,temperature (temp)and conditioning duration (T).Benmokrane et al.[33] investigated that moisture absorption rises with an increase in the size of rebar.ASTM (2008) [42] presents a standard test method for moisture absorption up to 24 hrs at 23 °C,beyond which the further change in the moisture absorption is significant.Moreover,absorption of moisture is greatly dependent upon temperature,diameter of the bar,as well as duration of conditioning,which subsequently affects the retention of tensile strength.Hence,the authors argue that the effect of moisture uptake is indirectly incorporated.Suffi-cient literature is available on the accelerating aging of GFRP bars in simulated concentrated alkaline solutions.The earlier studies reported two types of accelerating aging approaches,i.e.,bare bars[12,43,19,32,31] and concrete embedded bars [12,16,40,20,13],aged in concentrated alkaline solution under elevated temperatures.

With the recent development in artificial intelligence (AI) techniques [44,45],intelligent models have been formulated in many studies to assess the performance of Fiber-reinforced Polymers(FRPs) and composites [ 46-50,41,51 ].Naderpour et al.[52] developed a neural network model to predict the shear resistance of FRP bars in concrete.Adaptive neuro-fuzzy inference system(ANFIS) is a widely-used AI technique to solve civil engineering problems [53,54].Several researchers proposed metaheuristic algorithms to optimize the already developed fuzzy inference system(FIS) [55,56].Metaheuristic optimization algorithms are widely employed techniques for the development of efficient hybrid models[57].Integration of ANFIS model with genetic algorithms (GA) [58],particle swarm optimization (PSO) [59],ant colony optimization[60],shuffled frog-leaping algorithms [56],gray wolf optimization[61],firefly algorithms (FA) [62],support vector machine (SVM)[ 63,64 ],differential evolution [65],and imperialist competitive algorithms (ICA) [66] have been deployed successfully for the optimization of FIS.AI models optimized with these algorithms make the predictions more accurate due to their non-linear capability and yield models that can be used to avoid extensive laboratory testing in the future.It has been observed that there are very limited studies concerning intelligent models incorporating AI for predicting the TSR of post-conditioned GFRP bars.The long-term tensile reflection of the performance of GFRP rebars,environmental reduction factor (i.e.,C E) can be determined after the accelerating aging results for the machine learning model are available.Iqbal et al.[41] developed three AI models,i.e.,Gene Expression Programming (GEP),Artificial Neural Network (ANN),and ANFIS models to predict the TSR of GFRP bars in concrete environments.All three models exhibited close agreement between experimental and predicted results [67,68].For the sake of attaining higher accuracy,it is believed that these developed models can be further be optimized using advanced optimization algorithms.

Since the durability investigation of GFRP rebars in the harsh environment depends on various factors [69] found that It is a highly non-linear problem.The integration of AI models with optimizing algorithms has been proved to enhance the accuracy of the developed models [70–73].Therefore,the current study focuses on developing an FIS structure after integration with variety of algorithms,such as,PSO,GA,and SVM,to investigate the most effi-cient optimization technique for the reliable prediction of the TSR of aged GFRP bars.The developed model is reliable and can be extrapolated more precisely in order to investigate the environmental reduction factor.The remaining paper is organized as follows.Firstly,a brief introduction to the prediction and optimization approach is presented in Section 2.It is followed by the description of development of the optimized models and evaluation criteria in Section 3.The subsequent section describes the results and discussion.Lastly,Section 5 presents the conclusions of this study pertaining to the prediction of TSR of conditioned GFRP bars.

2.Materials and method

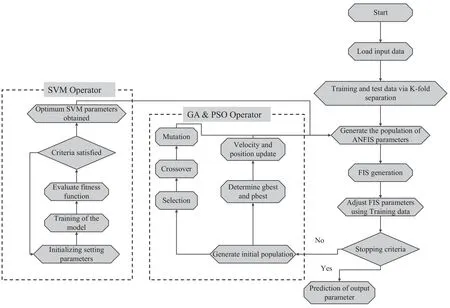

Fig.1 depicts the graphical methodology explaining various activities for predicting and optimizing the TSR of the conditioned GFRP bars.

Fig.1. Graphical methodology for the developed models.

Firstly,the parameters affecting the degradation of GFRP bars in alkaline environment as identified by Iqbal et al.[41] were collected from the previous literature.The fuzzy metaheuristic ensembles were developed deploying an extensive experimental database comprising 715 tested specimens (resulting from 151 data points) under different accelerated conditioning environments.The data employed for developing fuzzy-metaheuristic models is adopted from Iqbal et al.[74] and Iqbal et al.[69].The properties of GFRP bars used in this study are according to ASTM D7957/D7957M-17 [75].The details of the data used in the development of models are given in supplementary data.It is important to note that the GFRP bars collected for the literature have a range of 8mm-16 mm diameter sizes.The range of volume fraction of E-glass fibers is between 0.48–0.75.Moreover,the extreme values of the pH of the conditioning solution suggest that the developed model can be used for a broader range of alkaline environments.The results of a few accelerating aging specimens conditioned for the longer duration exceeding one year were omitted from the study to reduce the data skewness.The statistical function (standard deviation,SD=18.03) for the input parameter i.e.,the temperature presents a wider range of accelerating aging temperatures.The developed models are considered suitable for the ranges of input variables as described from the statistical viewpoint.

In addition,the dataset was randomly partitioned into 80% training and 20% testing data [Please add a reference for the ratio].Secondly,three fuzzy metaheuristics algorithms (i.e.,PSO,GA and SVM),were deployed to propose the fuzzy models for optimizing the TSR.Thirdly,an appropriate structure of the respective metaheuristic model was determined after several trials and errors.Finally,the accuracy of models was evaluated using different statistical metrics.

2.1.Adaptive neuro-fuzzy inference system (ANFIS)

ANFIS is a blend of fuzzy inference systems and neural networks that was initially introduced by Jang [76].The fuzzy inference system (FIS) of ANFIS can establish complex mapping relations.This enables FIS suitable for experiencing fuzzy knowledge.The inputs and target variables are connected using learning and training data in the case of the conventional neural network.In contrast,ANFIS cannot comprehend the logical thinking of the human mind.It extracts the hidden rules in the data [77].The structure of ANFIS is a five-layered adaptive network Fig.2) that comprises membership functions for each input which indicates fuzzification in its first layer.This layer is responsible for converting input values into fuzzy sets.The results in this step are produced employing various membership functions,for instance,trapezoidal,triangular,bell,and Gaussian function represented by Eqs.(1) to((4) [78],wherea,b,c,d,andσare the preinstalled parameters of the MFs.It is followed by a rule layer that calculates the firing strength of each rule.The subsequent layer normalizes the firing strengths.Whereas,the fourth layer,consisting of Takagi-Sugeno fuzzy interface system,is used for the defuzzification of outputs.The final layer computes the sum of outputs of the fourth layer of a neuro-fuzzy system in the form of overall output.

Fig.2. A typical five-layered ANFIS Architecture [79].

2.2.Particle swarm optimization (PSO)

The concept of swarm intelligence in the issues related to artificial intelligence was developed consequent to the inspiration from cognitive psychology,neurosciences,behavioral sciences,and social ethology [80].PSO is mainly used for optimization problems because the conventional framework of artificial intelligence neglects the basic contribution of sociality [81].It is an intelligent algorithm that was first proposed based on the behavior of swarms in certain ecological systems [ 82,45 ].Each individual of the population is represented as a particle,represented in the form of a point,in D -dimensional space.These particles have position vectors and velocity vectors which are governed by their evolutionary state in a particular search space.Consider that,D is a dimensional number,particleiholds the position vector Pi=(pi1,pi2,pi3,….piD)and Velocity vector Vi=(vi1,vi2,vi3,…viD).The particle position vectors are updated in search of an optimal solution by the rule during the learning iteration of PSO,as given in Eq.(5).In Eq.(5),Videnotes the velocity vector of particle,tandt+1represent two consecutive iterations.The velocity vector is updated by rule given in Eq.(6),such that the inertial component prevents the particle from changing its position drastically,social component tends to occupy the best position of the whole swarm and the cognitive component contributes to return the particle to its previously best position.Wherepbestidenotes the personal best position searched byithparticle,andgbestiis the global best position searched by the swarm so far.The optimum values for acceleration coefficientsc1andc2,random numbersr1andr2in the range of [0,1],and the inertial weight (w) depend on multiple iterations for a specific problem.

2.3.Genetic algorithm (GA)

It was initially developed by De Jong [83] subsequent to the inspiration from the Darwinian theory of evolution [ 45,66 ].It is also a population-based algorithm working on the principle of the survival of the fittest.GA comprises genes and chromosomes;each parameter represents a gene,where every solution is linked to a chromosome.This algorithm assesses the fitness condition of each individual in the population employing an objective function which is also termed as a fitness function.The solution is randomly chosen based on the selection procedure,just as the roulette wheel mechanism [84].The stochastic behavior of GA makes its reliability questionable.However,it is noteworthy that its process includes maintaining the best solution in each generation and employing them to improve other solutions.Sampson [85] used crossover,mutation,recombination,and selection for the first time in artificial systems.These operators help optimize the solution such that crossover contributes to exploiting the area between two-parent solutions.The mutation allows other solutions towards the global optimum.GA can deal with various optimizations,depending on the type of fitness function,whether static,change with time,continuous or discontinuous,and linear or non-linear.Furthermore,it starts with a random population of solutions for addressing a particular problem.The working of GA can be illustrated in the following main points [86] ;

1 Random population is generated based on Gaussian random distribution to enhance the diversity of the population.The population encompasses genes and chromosomes simulating variables and solutions.In this step,population (variable and solutions) are spread around the search space.

2 Natural selection,which is the beauty of this algorithm,is initiated in the 2nd step.The fittest individual has a high probability of getting the food.Based on the fitness function of individuals,they are assigned weighted probabilities based on which they are selected to produce the next generation.

3 Naturally,the chromosome in the genes of males and females are combined to produce a new chromosome.This way,the individuals selected termed as parent solutions in the above step are used to create next-generation (children solutions).The new generation is produced based on swapping the chromosomes of the parent solution by single or double cross-over point.

4 Finally,the mutation is used to alter genes after creating the next generation to maintain the diversity of the population.In this study,the uniform cross-over,the roulette wheel selection,and bit string mutation operators were used for the development of a hybrid ANFIS-GA model.

2.4.Support vector machine (SVM)

Support vector (SV) algorithm was initially developed by Vapnik [87] and Vapnik [88],which is a non-linear extension of the generalized Portrait algorithm.Two primary types of SVM include support vector regression (SVR) and support vector classification(SVC) [ 89,45 ].This algorithm aims to find a hyperplane classifying the data points in multidimensional space.The input data set is mapped to a high dimensional feature space to address the SVM problem by introducing a non-linear mapping function [90].Consequently,non-linear relationships between input data and output data are formulated in the form of hyperplane using a linear functionf(x) and are given by Eq.(7).f(x) denotes the predicted value;ϕ(x) is a non-linear mapping function;wandbare coefficients calculated by optimizing empirical risk as shown in Eq.(8).L∈(y,f(x)) is the∊-insensitive loss function.SVR function is finally represented as Eq.(9).,αiare Lagrange multipliers andK(xi,x) is kernel function (Gaussian is a commonly used kernel function).

It is important to mention that the SVM learns both linear (simple) and nonlinear (complex) mapping functions.ω,b,xandφ(x) are the weight vector,scalar bias or threshold,input data or training sample,and high-dimensional feature spaces that are nonlinearly mapped from the input space x,respectively.ωandbcan be calculated by minimizing the regularised risk functions.

3.Optimization models

3.1.Developing soft computing techniques

Several membership functions (MFs) were included in each input parameter of ANFIS such that every individual MF maximizes somewhere.However,no specific formulae generally exist to predict the numbers and type of MF [91] ;therefore,a trial and error hypothesis was used to select the MFs.Furthermore,the metaheuristic optimizations (i.e.,PSO,GA and SVM),were employed here to enhance the precision and accuracy of the developed ANFIS model and further improve the training process by optimizing the position of MFs.First,the data comprising inputs and outputs was arranged for K fold cross-validation (K-FCV) stage.Next,the parameters were randomly initialized to develop the ANFIS structure.Simultaneously,the fuzzy c-mean (FCM) clustering technique was employed during the formulation of ANFIS model to build a FIS and optimize the result.Consequently,PSO,GA and SVM were used to update the premise and consequent parameters.

The initial population was generated in the case of ANFIS-GA algorithm,and the genetic operators were arranged to devise the parameters and various rules required to generate the ANFIS model.The algorithm was based on backpropagation and the least square method,which helps to train the FIS according to the fitness function.The respective error between the designated values and FIS prediction was measured afterward.Then,the genetic operators were applied to produce the new population if the optimum criteria were not achieved.The schematics are depicted in Fig.3.

Fig.3. Flowchart of fuzzy metaheuristic models.

The optimum ANFIS parameters,in the case of ANFIS-PSO,were selected based on a variety of parametric studies.It depends on key parameters such as maximum numbers of particles,maximum iterations,damping ratio,inertial weight,cognitive and social acceleration to estimate each dimension of the particle.The initial population was generated after the selection of parameters.Once the particles are initialized in the PSO algorithm,they adjust their position and velocity in the space to achieve convergence (Fig.3).After optimizing the model,the fitness function was evaluated,and the most appropriate parameters were selected for developing the ANFIS model [92].

Similarly,in the ANFIS-SVM hybrid model,the SVM randomly divides the data into training and testing data while the setting parameters are initialized randomly.The model was evaluated using fitness function,and once it was optimized,the best parameters were selected for the FIS generation (Fig.3)

3.2.Performance evaluation

The performance of the developed hybrid models was evaluated using commonly used statistical indices.In addition,the coefficient of determination (R2) and root mean square error (RMSE) functions were used,as suggested by multitude of researchers in previous prediction models [ 68,93,94,41 ].The R2value of 1.0 and RMSE of 0 reflect the perfect level of accuracy,thus the value of R2greater than 0.8 implies a good predicting result [95–97].The mathematical relations for these statistical indices are given in the form of Eqs.(10) and (11),whereYexpis experimental value;YPreis predicted value by the model;Ymis the mean of y data;and n is the total number of data.

4.Results and discussions

The TSR of conditioned GFRP bars was predicted through various ensemble machine-learning techniques.The reliability of the developed models depends on the ratio of data points to the selected input parameters whose minimum value must be larger than 5 [95].The current models were developed using 715 tested specimens with 5 input parameters;hence this ratio (≈30) is far beyond the minimum requirements.For preparing the dataset,the normalization process was first performed wherein the output and input parameters were normalized in a predefined range.In order to simplify the modeling,Eq.(12) was used to normalize the data before the training of the models in a range of [0,1],where Yn,Ymax,and Yminare normalized,maximum and minimum data for each parameter,respectively.

In this study,the data was divided into training data,and testing data sets,i.e.,80% of the total data to establish the model and 20% to test the developed model [91] To verify the network performance,K-fold cross-validation method was applied.In this regard,the subsequent learning and validation stages were repeated using the K-fold cross-validation.All data was divided into five subsets(S1,S2,S3,S4,and S5).Then,the data (S2 to S5) were utilized as the learning data,and the (S1) data were used for cross-validation.This operation is repeated to cover all the data,and the final crossvalidation is done by averaging the cross-verification performance of the K models.The experimental results of this work were performed on an Intel(R)CoreTMi7–4790 CPU and 8 GB RAM using Matlab software.

4.1.ANFIS modeling

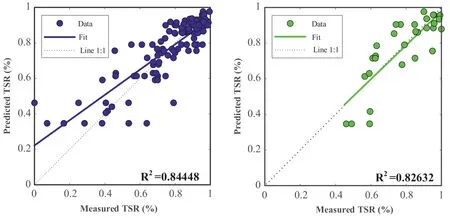

To employ the ANFIS model,it is necessary to select the type and number of MFs and iteration numbers beforehand.Based on the literature,there are no explicit formulas for forecasting the MFs [91].Therefore,the MFs are determined through the process of trial and error.Moreover,the optimal parameters are attained from the Gaussian membership function.Fig.4 shows the relation between the training and testing dataset for predicting the TSR of the GFRP bars.From Fig.4,for the measured and the predicted TSR,the value of R2is 0.8448 and 0.82632 for training and testing data,respectively,which are all above 0.80.

Fig.4. Relation between measured and forecasted tensile strength values using the ANFIS technique;(a) training set,and (b) testing set.

4.2.Optimizing proposed hybrid models

MATLAB 2019b environment was employed to optimize the TSR with the help of hybrid AI models [98–100].During the predictive network preparation,three fuzzy metaheuristic algorithms were used for optimization.PSO,GA,and SVM were integrated with the traditional ANFIS method.The major role of techniques based on population is to optimize the performance of the conventional ANFIS model throughout the analysis and set hyperparameters for optimization.In the current study,the three algorithms train the ANFIS parameters and determine their optimal values.The potentially effective five parameters (i.e.,db,Vf,pH,temp and T) were set as input variables [41],whereas the TSR was kept as the output parameter.Several trials were conducted to select the influential values of parameters used in the training of the GA model.Based on these trials,crossover and the mutation rates were selected as 0.7 and 0.01,respectively.

The hyperparameters of PSO were adopted according to the parametric studies for developing the ANFIS-PSO technique.The PSO contributes such that the ensemble model predict the relationship more accurately.Hence,the ensemble model can achieve higher accuracy for the no-linear relations,thereby ameliorating the TSR results.Note that the damping inertia weight (ωdamp),initial inertia weight (ωmin),social coefficient (SC),and acceleration rate (Ar) are the main parameters of the PSO.The optimum values of PSO were achieved using the trails and errors method.Hence,Wdamp,Wmin,SC,and Ar,were set as 0.98,0.5,2,and 1,respectively.

Similarly,several attempts were performed to select the parameters for the SVM for developing ANFIS-SVM hybrid model.For the sake of optimization,the well-known Gaussian radial basis function (RBF) was used as the kernel function.The regression results for the training and testing phases are presented in Fig.5.The regression is calculated as the slope of values between the measured and predicted TSR.From Fig.5,all three models accomplished good predictions of TSR.Furthermore,the developed models exhibited higher accuracy in defining the relationship of TSR and the stated influential factors (i.e.,the training dataset) in contrast to estimating the TSR for any unseen data (i.e.,the testing dataset).The slope of the regression line between the measured (x-axis) and predicted(y-axis) closer to one represents the higher accuracy of the model[94,68,41,79,101,93].

Fig.5. Relation between the experimental and forecasted tensile strength values for training and testing datasets;(a) ANFIS-PSO,(b) ANFIS-GA,and (c) ANFIS-SVM techniques,respectively.

Fig.6 shows the correlation among the experimental and predicted tensile strength for all the datasets to introduce a visual sense for the developed models.All of the developed models have relatively good performance in predicting TSR values.

Fig.6. A comparison between the experimental and predicted TSR for all datasets;(a) ANFIS-PSO,(b) ANFIS-GA,and (c) ANFIS-SVM.

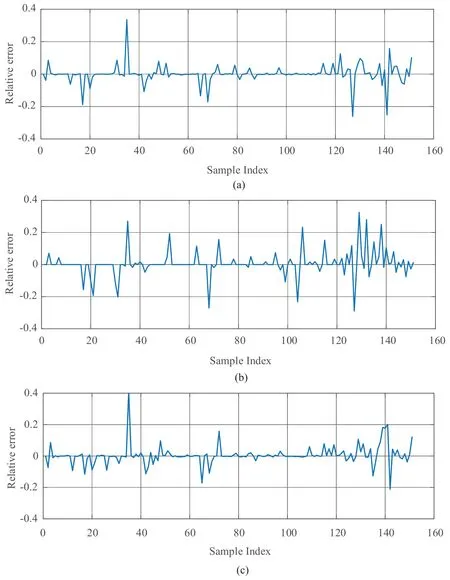

4.3.Error analysis

Fig.7 shows the error analysis for the developed models;the relative error of forecasting outputs for all ensemble-heuristic models is plotted against the measured data of tensile strength.The relative error of the developed models can be observed as mainly concentrated around zero error,thus proving a robust agreement among experimentally measured TSR values and the predicted values.Additionally,the forecasted dataset obtained from ANFIS-PSO and ANFIS-SVM techniques can more accurately track the experimental dataset than ANFIS-GA.Fig.8 shows the assessment results of the generated models compared with those of ANFIS model.ANFIS-PSO,ANFIS-GA,and ANFIS-SVM yielded R2and RMSE of (0.878,0.076),(0.844.0.082),and (0.907.0.075),respectively for the testing datasets.Hence,the hybrid ANFIS-SVM algorithm has the lowest RMSE=0.075 and the highest R2=0.907,while the ANFIS model has RMSE=0.124 and R2=0.826.Because of lower RMSE and higher values of R2,the ANFIS-SVM algorithm outperforms the other models in terms of performance.

Fig.7. Relative error for all datasets;(a) ANFIS-PSO,(b) ANFIS-GA,and (c) ANFIS-SVM.

Fig.8. Comparison of performance indices for different models;(a coefficient of determination,and (b) root mean square error.

4.4.Sensitivity analysis

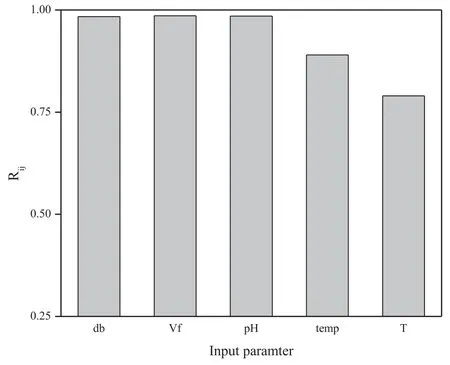

Sensitivity analysis is carried out to explore the general ability of the proposed methods.The sensitivity analysis is performed to estimate the influence of each input variable on the output.Generally,increasing the number of input variables helps provide more information and a preferable model;however,few input variables may contribute very little and act as noise for the algorithm.Yang,Zhang [102] Eq.(13) was applied to show the effect of diameter of the bar (db),fiber volume fraction (Vf),pH value (pH),Temperature (temp),and duration (T) on TSR [97].The symbolsmiandmjdenote the input and output parameters,andnis the number of data points.A simulated dataset was created such that only one of the input parameters was kept changing.Simultaneously,the other ones remained at their average values,and 10 simulated data points were taken for each variation,as shown in Table 1.

The value ofRijranges between 0 and 1,which shows the strength of the relation betwwen every input variable and the output.Fig.9 manifests the results ofRijcalculated for the developed models.It can be seen that the diameter of GFRP bar,volume fraction of E-glass fibers,and pH of the conditioning solution are more effective than other two parameter on TSR.This suggests that the diameter of the bar and volume fraction,are the most essential attributes to be considered in the design of FRP reinforced concrete structures.

Fig.9.Influence of each input parameter on the output.

5.Conclusions

The durability of GFRP bars in harsh environmental conditions has been a challenging issue in structural engineering.For this purpose,previous research explored accelerating laboratory aging of GFRP bars in harsh environments to investigate its short-term performance.The long-term durability is extrapolated using few empirical relations,subsequent to accelerating aging.The environmental reduction factor is used in various codes to reflect the longterm performance of GFRP bars in harsh environments,which is based on TSR of conditioned specimens.To avoid laboratory aging before durability evaluation,this study presents the formulation of three robust metaheuristic models for predicting TSR using PSO,GA,and SVM that is integrated with ANFIS.In this way,the computational efficiency and feature exploitation of the ANFIS approach was optimized using the three heuristic algorithms.Furthermore,the network performance results are presented in different ways to estimate the best-fit predictive network.The following conclusions can be drawn:

1.The three developed models (i.e.,ANFIS-PSO,ANFIS-GA,ANFISSVM) are reliable methods to estimate the TSR of conditioned GFRP bars.A value of R2greater than 0.84 for both the training and testing data reflects the close agreement between the experimental and predicted values.

2.For testing data of ANFIS model,its R2equals to 0.826.The values of R2for the test data of optimized model manifested 0.878,0.844,and 0.907 for ANFIS-PSO,ANFIS-GA,and ANFISSVM,respectively,which reveals the good optimization capability of these three models.

3.The comparison of the results showed that the weights and features determined by the SVM construct a more promising ANFIS model compared to GA and PSO.The developed model can be readily applied to predict the long-term durability of the GFRP bars in a concrete environment.Moreover,these models can also be used to extrapolate the environmental reduction factors more precisely,employing Huang and Abutaha model and Arrhenius relation,among others.

4.The sensitivity analysis of the developed hybrid models showed that the diameter of the bar,volume fraction of fibers,and pH of the surrounding solution are the most influential parameters of TSR.For example,the diameter of GFRP bar has a considerable role in the durability of GFRP reinforced structures.

Declaration of Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The authors would like to acknowledge the resources provided by Shanghai Jiao Tong University that supported the literature study and the data collection.Nevertheless,The authors are grateful for the financial aid from the National Natural Science Foundation of China (12072192,U1831105) and the Natural Science Foundation of Shanghai (20ZR1429500).

Supplementary materials

Supplementary material associated with this article can be found,in the online version,at doi: 10.1016/j.joes.2022.03.011.

Journal of Ocean Engineering and Science2023年5期

Journal of Ocean Engineering and Science2023年5期

- Journal of Ocean Engineering and Science的其它文章

- New solitary waves and exact solutions for the fifth-order nonlinear wave equation using two integration techniques

- Numerical treatment of temporal-fractional porous medium model occurring in fractured media

- Optimal Kalman-like filter for a class of nonlinear stochastic systems

- Dynamic quantitative risk assessment of LNG bunkering SIMOPs based on Bayesian network

- New soliton wave solutions of a (2+1)-dimensional Sawada-Kotera equation

- Review of enhancement for ocean thermal energy conversion system