Preparation Technology of Wuwei Xiaoke Granules

Shengbin CHEN, Guangyuan XIE, Yulong WEI, Yanqiong HUANG, Xuanyang ZENG, Xiaomin DENG, Mingzheng HUANG

The First Affiliated Hospital of Guangxi University of Chinese Medicine, Nanning 530023, China

Abstract [Objectives] To optimize the extraction and preparation technology of Wuwei Xiaoke granules. [Methods] Taking the extraction rate of extract as the scoring standard, the water extraction technology was optimized by orthogonal test. The influence of the proportion of pharmaceutical excipients on the molding conditions of Wuwei Xiaoke granules was investigated using granule molding rate, solubility, moisture, granularity, water-soluble extract and microorganism examination as evaluation indicators, and the optimal molding technology was optimized. [Results] The extraction technology was soaking in water for 0.5 h and heat extraction twice for 1 h each time: adding 10 times the amount of water in the first time, and adding 8 times the amount of water in the second time. The best molding technology was: extract density 1.13-1.16 (55-60 ℃), extract:soluble starch=1:2, and 0.15% stevioside. [Conclusions] The water extraction technology and granule molding technology optimized by orthogonal test are reliable and stable, with good granular characteristics, easy oral administration and good solubility, which can maximize the comprehensive quality of Wuwei Xiaoke granules, and provide an effective reference for the preparation and production of Wuwei Xiaoke granules.

Key words Wuwei Xiaoke granule, Orthogonal test, Preparation technology

1 Introduction

Wuwei Xiaoke prescription is composed of Radix Ginseng, Radix Rehmanniae Praeparata, Herba Dendrobii, Rhizoma Coptidis and other 10 kinds of drugs. It is a clinical experience prescription for the treatment of type 2 diabetes, proposed by professor Deng Xiaomin from Endocrinology Department of The First Affiliated Hospital of Guangxi University of Chinese Medicine, with "harmonizing yin and yang, filling the five viscera, strengthening the body resistance and lowering blood glucose" as the general treatment principles. Under the guidance of the "five elements" theory in the (Huangdi’s)InternalClassic, Wuwei Xiaoke prescription proposes a treatment method of "adjusting yin and yang" to prevent and treat type 2 diabetes based on the relationship between visceral reinforcing and reducing and the five elements, five flavors and five viscera[1-3]. In the preliminary clinical observation[4-5], it was found that Wuwei Xiaoke prescription had obvious hypoglycemic effect and could effectively improve insulin sensitivity, thereby improving clinical symptoms. Therefore, in order to facilitate patients to preserve, carry and take the prescription, it is developed as granules. In this test, the stable and controllable optimal water extraction technology and granule molding technology was studied via orthogonal test, in order to provide the preliminary data for the preparation technology optimization test and the test basis for subsequent production.

2 Instruments and reagents

2.1 InstrumentsTQ-1.0M3multi-functional extraction thickener (Wuxue Shengchi Machinery Equipment Co., Ltd.); CH-200 trough mixer (Jiangyin Haishun Machinery Equipment Manufacturing Co., Ltd.); YK-160 swing granulator (Jiangyin Haishun Machinery Equipment Manufacturing Co., Ltd.); KZL-180 straightening granulator (Changzhou Lexing Drying Equipment Company); CT-C-II hot air circulation oven (Nanjing Tengyong Dry Heat Equipment Co., Ltd.); DYDK-40C117 automatic granule packaging machine (Tianjin Sanqiao Packaging Machinery Co., Ltd.); AL204 electronic balance [Mettler Toledo (Shanghai) Co., Ltd.].

2.2 ReagentsThe prescription medicinal materials including Radix Ginseng, Radix Rehmanniae Praeparata, Herba Dendrobii, Rhizoma Coptidis, Mume Fructus, Rhizoma Zingiberis, Herba Gynostemmatis Pentaphylli, Pheretima, fried Bombyx Batryticatus, and Glycyrrhizae Radix et Rhizoma were purchased from Guangxi Xianzhu Chinese Medicine Technology Co., Ltd.; soluble starch (batch No.:210401) was purchased from Anhui Shanhe Pharmaceutical Excipients Co., Ltd.; stevioside was purchased from Qufu Shengren Pharmaceutical Co., Ltd. Wuwei Xiaoke granule samples (batch No.:20220110, 20220112, 20220114) were provided by the drug manufacturing room of The First Affiliated Hospital of Guangxi University of Chinese Medicine. The strains used in this test includedStaphylococcusaureusCMCC(B)26003,PseudomonasaeruginosaCMCC(B)10104,BacillussubtilisCMCC(B)63501,CandidaalbicansCMCC(F)98001,AspergillusnigerCMCC(F)98003,EscherichiacoliCMCC(B)44102,SalmonellaparatyphiB CMCC(B)50094 (China Institute for Food and Drug Control).

Trypticase Soy Agar Medium (TSA), Sabouraud Dextrose Agar Medium (SDA), Trypticase Soy Broth Medium (TSB), Sabouraud Dextrose Broth Medium (SDB), McConkey Liquid Medium,etc.were all purchased from Guangdong Huankai Microbial Technology Co., Ltd.

3 Water extraction technology

3.1 Optimization of extraction conditions by orthogonal test

The main factors affecting water extraction are: soaking time (A), extraction solvent amount (B), extraction time (C), extraction times (D). The soaking time was set as 0.5, 1 and 2 h; the amount of extraction solvent was set as 8, 10 and 12 times the amount of water added; the extraction time was 1, 2 and 3 h; and the extraction times were 1, 2 and 3 times. Orthogonal test was conducted according to the L9(34) orthogonal test table. The factor levels are shown in Table 1.

Table 1 Orthogonal test factor levels of water extraction technology conditions

3.2 Extraction methodNine copies of medicinal materials (118 g/copy) were weighed according to the prescription ratio, and 9 tests were carried out according to the corresponding factors in the L9(34) orthogonal test protocol. The extracted liquid of each test was filtered by 80-mesh filter, merged and concentrated to 100 mL.

3.3 Determination of dry extract rateThe dry extract rate was used as the evaluation index to determine the technology. Precisely 20 mL of the above concentrated liquid was moved to an evaporating dish dried to constant weight, evaporated to dryness in a water batch, and dried at 105 ℃ for 3 h. Afterwards, the extract was moved to a dryer, cooled for 0.5 h, and quickly weighed. The results were calculated (Table 2).

Table 2 Data analysis and results of L9 (34) orthogonal test

As shown in Table 3, the influence on the extraction effect successively was D>C>B>A, but the variance analysis results showed that only D had significant differences on the extraction effect among the four factors (P<0.05). Combined with conventional production operation, A1B1C1D2was the preferred combination. Considering the hygroscopic properties of medicinal materials, 10 times the amount of water was added in the first extraction and 8 times the amount of water was added in the second extraction. Therefore, the optimal extraction technology was as follows: the medicinal materials were soaked in water for 0.5 h and heated for extraction twice, 1 h each time: adding 10 times the amount of water in the first time, and adding 8 times the amount of water in the second time.

Table 3 Variance analysis of extraction test

3.4 Verification testIn order to confirm the reliability and stability of the preferred technology conditions, the medicinal materials were weighed and tested according to the preferred technology conditions. The results are shown in Table 4.

Table 4 Technology verification results of water extraction test of medicinal materials

The above test results showed that the total solid yield obtained by protocol A1B1C1D2was basically consistent with the group that had the highest total solid yield obtained by orthogonal test (31.89%), indicating that the optimal technology conditions are reasonable, stable and reliable.

4 Molding technology

4.1 Choice of dosage formThe original Wuwei Xiaoke prescription was mainly prepared as decoction and had been used clinically for many years. However, there were many shortcomings, such as inconvenient to carry, large dosis, easy to mildew, as well as poor stability of liquid preparation. Therefore, solid dosage form, that is, granules, is taken into accounted, which not only is easy to preserve and carry, but also can improve the taste by adding a certain amount of corrigent, thus overcoming the above shortcomings.

4.2 Preparation of granulesThe extracts with different densities (1.13-1.16, 1.19-1.25 and 1.30-1.34 g/mL) were investigated in the preliminary test, and it was found that the extract with a density of 1.13-1.16 g/mL was easier to granulate and had a high molding rate. The medicinal materials were weighed at 5 times the amount of the prescription and extracted by the optimal water extraction technology: the medicinal materials were soaked in 10 times the amount of water for 0.5 h, decocted for 1 h, and filtered; the medicinal residue was decocted in 8 times the amount of water for 1 h, filtered by an 80-mesh filter; the filtrate was merged, and concentrated into the extract of about 1.13-1.16 (55-60 ℃); according to the ratio of extract:soluble starch=1:2, they were mixed with 0.15% stevioside, and prepared into soft materials; the wet granules were dried at 75 ℃, and the granules were organized to obtain the final product.

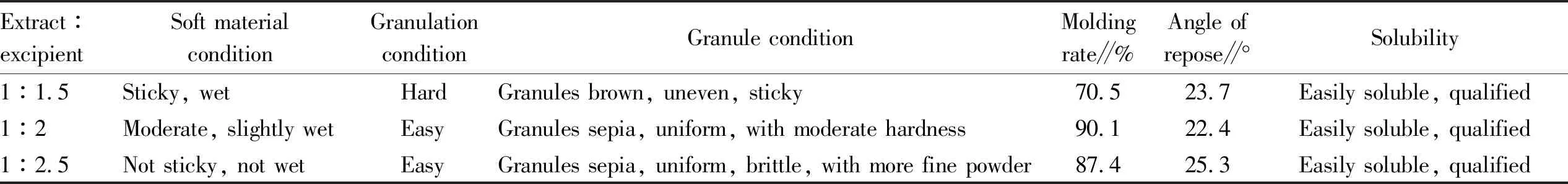

4.2.1Drug-excipient ratio. The extract was divided into 3 equal parts, to investigate different proportions of extract and excipients. As shown in Table 5, with the increase in the amount of excipients, the molding rate increased, and the soft material made of low proportion of excipients had large viscosity and adhesion, resulting in difficulties in granulation. When the drug-excipient ratio was 1:2 and 1:2.5, the soft materials were mixed well, not sticky, easy to granulate, uniform in granule size and high in molding rate. However, considering that a small amount of dosis would be better, the drug-excipient ratio was determined as 1:2 in comprehensive actual use.

Table 5 Optimization results of different drug-excipient ratios

4.2.2Drying temperature. According to the above optimized molding technology conditions, 4 parts of wet granules were taken and dried at 50, 60, 70, 80 ℃ for the same time. The measured molding rates were 81.6%, 82.4%, 90.2% and 89.6%, respectively. The results showed that the granules were sticky, and had more fine powder, low molding rate and high granule moisture content at 50-60 ℃, which did not meet the standards of theChinesePharmacopoeia(2020 edition). When the temperature was 70-80 ℃, the granules were uniform, with high molding rate and qualified moisture. Therefore, the drying temperature of wet granules was selected as 75 ℃.

4.2.3Drying time. After 4 equal parts of wet granules were dried at 75 ℃ for 3, 3.5, 4 and 4.5 h, the moisture content of the granules was determined as 8.42%, 7.76%, 3.72% and 3.05%, respectively. After drying for 0.5 h, the granules were loose, with more crushed powder, and the moisture content did not meet the standards of theChinesePharmacopoeia(2020 edition). After drying for 4.5 h, the granules were too brittle, fragile, and easy to absorb moisture. After drying for 4 h, the granules had good condition, suitable hardness and standard-compliant moisture content, so the drying time of granules was optimized as 4 h.

4.2.4Molding technology verification. Three equal parts of extract were prepared into Wuwei Xiaoke granules according to the above optimum molding conditions: extract:soluble starch=1:2, 0.15% stevioside, granulated with 12-mesh sieve, dried at 75 ℃, and organized granules. According to the above evaluation indexes, the granules were verified. The results showed that the soft material was moderate and was easy to granulate; the granules had uniform size and moderate hardness, and the qualified rate of the granules was 91.3%. After 3 batches of parallel operation, the granules had an average qualified rate of 91.2%, qualified solubility, and good fluidity (angle of repose <40°), indicating that the molding technology is stable and reliable.

5 General inspection of granules

5.1 Appearance inspectionThree batches of prepared granules were sepia with uniform size, consistent color, mild flavor, no adhesion or moisture absorption, which met the standards of theChinesePharmacopoeia(2020 edition).

5.2 Granularity inspectionThe granularity of Wuwei Xiaoke granules was determined according to the Second Method (double sieving method) of General Rule 0982 in theChinesePharmacopoeia(2020 edition). The results showed that the total percentages of granules that could not pass the No. 1 sieve but could pass the No.5 sieve in the 3 batches of Wuwei Xiaoke granules were 0.62%, 0.67% and 0.76%, respectively, with an average value of 0.68%, all less than 15%, which met the standards of theChinesePharmacopoeia(2020 edition).

5.3 Moisture inspectionThe moisture content of Wuwei Xiaoke granules was determined according to the Moisture Determination Method (drying method) of General Rule 0832 in theChinesePharmacopoeia(2020 edition). The results showed that the measured water contents of the three batches of Wuwei Xiaoke granules were 3.07%, 3.56% and 3.28%, respectively, with an average value of 3.30%, all less than 8.0%, which met the standards of theChinesePharmacopoeia(2020 edition).

5.4 Solubility inspectionThe test was carried out according to the solubility requirement of 0104 Granules in the Volume IV of theChinesePharmacopoeia(2020 edition). Precisely 10.00 g of Wuwei Xiaoke granules were taken and added with 200 mL of hot water by stirring for 5 min, and 3 batches of parallel operation were conducted. It was observed that all granules were dissolved, which met the standards of theChinesePharmacopoeia(2020 edition).

5.5 Determination of water-soluble extractsThe water-soluble extracts of Wuwei Xiaoke granules were determined according to the 2201 Cold-maceration for Determination of Extracts of the Volume IV General Rule in theChinesePharmacopoeia(2020 edition). Approximately 4 g of samples were taken and conducted 3 batches of parallel operation. The results were 25.34%, 23.05%, 22.47%, with an average of 23.62%. Considering objective factors such as personnel operation and different instruments and equipment, it is temporarily stipulated that each batch of water-soluble extract of Wuwei Xiaoke granules shall not be less than 20.00%.

5.6 Microbial limit testAccording to the Microbiological Limit Standard for Non-sterile Products (1107) of the Volume IV General Rule in theChinesePharmacopoeia(2020 edition), the preparation should determine the total number of aerobic bacteria, mould and yeast, and examine the control bacteria:EscherichiacoliandSalmonellaspp. And the applicability test of the selected method should be carried out. The results showed that the total number of aerobic bacteria, mould and yeast were all less than 10 cfu/mL, and noE.coliorSalmonellaspp. had been detected, which met the standards of theChinesePharmacopoeia(2020 edition).

6 Scale-up results of pilot production

Wuwei Xiaoke granules were prepared according to the above optimal molding conditions. Three batches of pilot products (theoretical yield 50.0 kg/batch) were operated in parallel. In the process of scale-up production, it showed smooth production, good reproducibility, and qualified quality indicators (Tables 6-8). It can be seen that the formulation technology of this product is stable and controllable, and is suitable for industrial production.

Table 6 Extraction parameters of three batches of Wuwei Xiaoke granules pilot products

Table 7 Preparation parameters of three batches of Wuwei Xiaoke granules pilot products kg

Table 8 Inspection results of three batches of Wuwei Xiaoke granules pilot products

7 Discussion

On the basis of single factor study, the water extraction technology of Wuwei Xiaoke prescription was optimized by orthogonal test. Considering the hygroscopic property and energy-saving cost factors of medicinal materials, the optimal extraction technology was soaked in water for 0.5 h and heat extraction twice for 1 h each time: adding 10 times the amount of water in the first time, and adding 8 times the amount of water in the second time.

Preparing granules by adding soluble starch to the prescription extract can not only enhance the stability of the active ingredients but also improve the hygroscopicity of the extract and reduce the difficulty of granulation. In this study, the difficulty of granulation, granule molding rate, solubility, water content, granularity, water-soluble extract and microbial examination were selected as evaluation indicators. The optimum preparation technology was: extract density 1.13-1.16 (55-60 ℃), extract:soluble starch=1:2, 0.15% stevioside; they were mixed and prepared into soft materials; the wet granules were dried at 75 ℃ for 4 h, and then organized to obtain the final product. The preparation technology is reliable and stable, with good granular characteristics, good solubility and easy preservation, which can maximize the comprehensive quality of Wuwei Xiaoke granules, and provide an effective reference for the preparation and production of Wuwei Xiaoke granules. Moreover, it can provide stable granules for the further study of drug efficacy and quality standard control.

- Medicinal Plant的其它文章

- Progress in the Application of Network Pharmacology in Mongolian Medicine Research

- Anti-tumor Effect of Paclitaxel Enhanced by Psoralen at the Cellular Level

- Preparation Process of Plumbagin Nanomicelle In-situ Gel

- Therapeutic Effect of Daphnetin on Mastitis Induced by Staphylococcus aureus in Mice

- Current Status and Prospects of Drugs for Ischemic Stroke Treatment

- Activity Screening Study on the Anti-tumor Effects of Extracts from Mahoniae caulis