Skyrmion transport driven by pure voltage generated strain gradient

Shan Qiu(邱珊) Jia-Hao Liu(刘嘉豪) Ya-Bo Chen(陈亚博) Yun-Ping Zhao(赵云平)Bo Wei(危波) and Liang Fang(方粮)

1Institute for Quantum Information&State Key Laboratory of High Performance Computing,College of Computer,National University of Defense Technology,Changsha 410073,China

2Hunan University of Humanities Science and Technology,Loudi 417000,China

The magnetic skyrmion transport driven by pure voltage-induced strain gradient is proposed and studied via micromagnetic simulation. Through combining the skyrmion with multiferroic heterojunction,a voltage-induced uniaxial strain gradient is adjusted to move skyrmions. In the system,a pair of short-circuited trapezoidal top electrodes can generate the symmetric strain. Due to the symmetry of strain,the magnetic skyrmion can be driven with a linear motion in the middle of the nanostrip without deviation. We calculate the strain distribution generated by the trapezoidal top electrodes pair,and further investigate the influence of the strain intensity as well as the strain gradient on the skyrmion velocity. Our findings provide a stable and low-energy regulation method for skyrmion transport.

Keywords: skyrmion,strain gradient,multiferroic heterojunction,spintronics

1. Introduction

Magnetic skyrmions are topologically protected quasiparticle spin structures.[1–5]Due to their small size[6]and low driven energy consumption, skyrmions are considered a strong competitor in the next generation of spintronic devices,such as information storage,[7]artificial synapses,[8]and nanooscillators.[9]Towards future applications,successful manipulation of skyrmions is the key. Previous work have shown that skyrmions could be generated and manipulated by using different methods, including external magnetic field,[10,11]temperature gradient,[12,13]microwave,[14]spin wave,[15–17]spinpolarized current,[18–22]and electric field,[23,24]etc.Among them, the spin-polarized current is the most widely used method in driving the skyrmion. However, the skyrmion Hall effect is inevitable during the skyrmion motion driven by the spin–orbit torque, which makes the skyrmion deviate to a certain boundary of the nanostrip, and finally, get annihilated.[25,26]

In recent years,the electric field-generated strain has been experimentally proved to be an effective switching magnetic structure method.[27–30]The strain in the multiferroic heterojunction, which is a ferromagnetic/piezoelectric double-layer composite structure,can be generated by applying a voltage to the piezoelectric layer,and then acts on the ferromagnetic material layer by the inverse magnetostriction effect to control the ferromagnetic layer’s magneto-dynamic characteristics.[31–35]Based on this strategy,some groups have successfully realized the electrical manipulation of magnetic skyrmion creation and annihilation in experiments.[36–38]In particular, the skyrmion transport was also demonstrated using electric fieldgenerated strain gradients. Currently, Liuet al.[39]demonstrated that strain gradient could adjust the skyrmion transverse velocity as the magnetic skyrmion was driven by the in-plane current in a nanotrack.Yaneset al.[40]proposed the skyrmion motion via a strain gradient generated by the voltage between electrodes on a piezoelectric layer. However,this method inevitably results in the limitation of the transmission distance of skyrmions.

Here we report a skyrmion transports method driven by voltage-generated strain gradient without the assistance of current or magnetic field. The nanostrip is constructed between a pair of short-circuited trapezoidal top electrodes on the piezoelectric layer. The bottom electrode under the piezoelectric layer is grounded.Through finite element simulation,we show that applying a voltage between the top electrodes and the bottom electrode on both sides of the piezoelectric layer can generate a strain gradient on the nanostrip. Due to the symmetry of the strain,the skyrmion can be stabilized on the linear trajectory of motion,avoiding the skyrmion-Hall-effect transport deflection. In addition,we calculate the effects of strain intensity and strain gradient on skyrmion transport speed. Our discovery bridges a new way for ultra-low energy voltage regulation in the multiferroic heterojunction and reliable skyrmion transport.

2. Model and device structure

When a ball is subjected to a symmetrical force, it will maintain a stable state. But when the force at both ends produces a gradient,the ball will be“squeezed”to the side where the force is smaller,as shown in Fig.1(a). Based on the inspiration of this phenomenon,we analogize it to skyrmion transport regulation. As shown in Fig. 1(b), when skyrmions in the nanostrip are subjected to a symmetrical force in the vertical direction of motion,they can remain stable on the straight line of motion, avoiding the skyrmion Hall effect. When a force gradient is generated in the direction of movement, the skyrmion will be “squeezed” to the side where the force is smaller,resulting in a directed linear motion.

Fig. 1. (a) Ball motion driven by pressure gradient. (b) Skyrmion motion driven by pressure gradient. (c)Skyrmion transport system with strain gradient generated by the voltage.

Figure 1(c) is the skyrmion transport system with strain gradient generated by the voltage. The piezoelectric layer material is PZT(Pb(Zr,Ti)O3),[41]and the bottom Au electrode is grounded. A pair of trapezoidal short-circuited Au top electrodes are constructed on the surface of the piezoelectric layer,and a Pt/Co/Ta three-layers nanostrip is grown between the top electrodes. The Pt/Co/Ta trilayer stack with asymmetric interfaces[42–44]superimposes the interfacial DMI,stabilizing N´eel type skyrmions.Applying a voltage between the top electrodes and the bottom electrode will generate an in-plane uniaxial strain in the direction which is perpendicular to the long axis of the Pt/Co/Ta nanostrip.[45,46]Since there is a distance gradient between the two trapezoidal top electrodes, the generated strain will also form a strain gradient on the Pt/Co/Ta nanostrip, thereby promoting the movement of skyrmion in the nanostrip.

3. Results and discussion

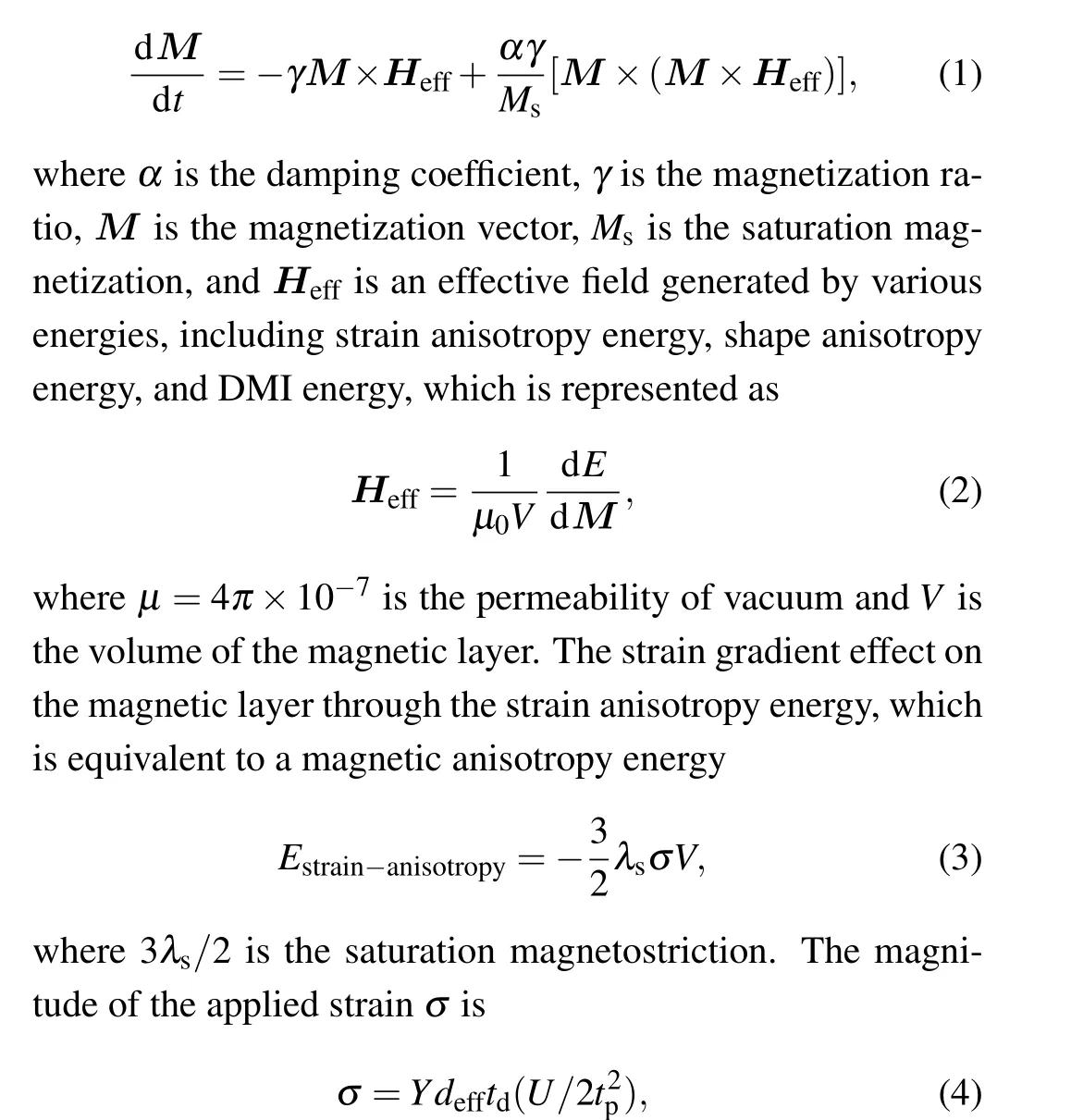

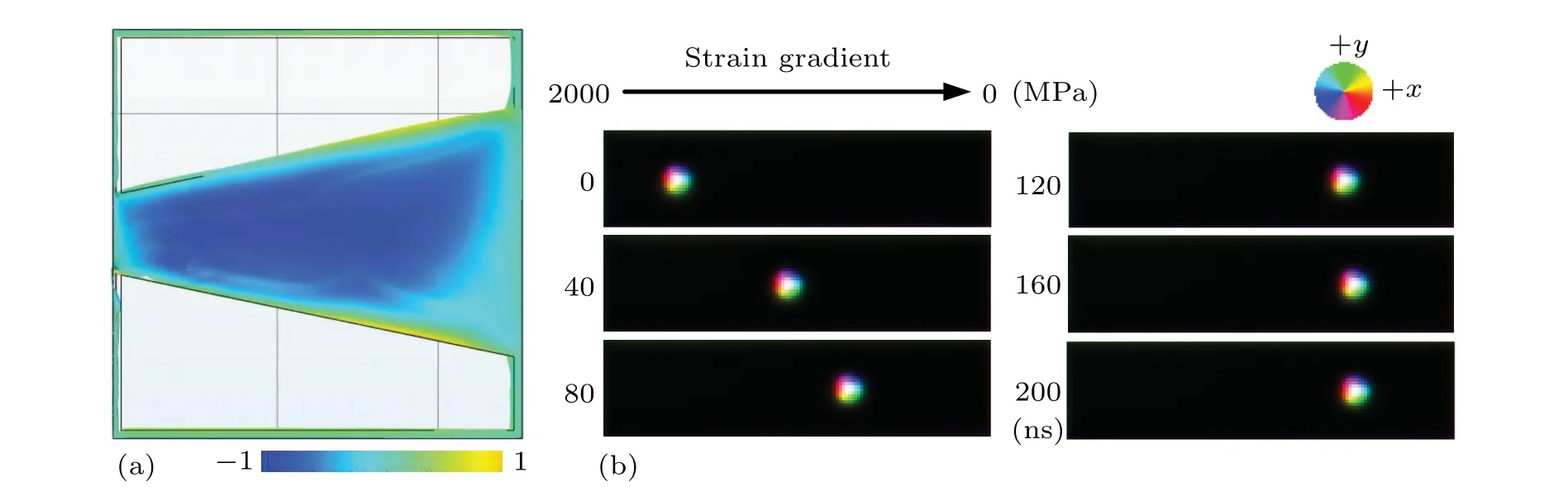

We first use COMSOL software to calculate the uniaxial strain distribution on the surface of the piezoelectric layer.The normalized uniaxial strain intensity distributions are simulated by finite element calculation using COMSOL Multiphysics software. We use‘linear elastic materials’and‘piezoelectric materials’in the“solid mechanics”module to simulate the piezoelectric layer and apply the voltage through the“electrostatic”module.Subsequently,the voltage action on strain is coupled through‘piezoelectric effect’in“multi-physical field”module. Finally, the strain distribution is obtained by constructing free tetrahedral mesh and steady-state solver. The calculation result is shown in Fig. 2(a). The color shows the normalized uniaxial strain intensity distribution. According to the report by Cuiet al.,when the top electrode spacing is 1 to 2 times the thickness of the piezoelectric layer, the generated local strain reaches the maximum.[47]The size of the square piezoelectric layer in the simulation is 5 mm×5 mm and the thickness is 0.5 mm. The length of the trapezoidal top electrodes is 4.9 mm, the short side is 0.9 mm, the long side is 1.9 mm, and the thickness is 100 nm. The distance between the two trapezoid electrodes gradually increases from 1 mm to 3 mm. The bottom electrode has the same size as the piezoelectric layer,and the thickness is 200 nm. A voltage of 400 V is applied between the top electrode and the bottom electrode.When the system is stable, as shown in Fig. 2(a), an obvious uniaxial strain gradient will be generated between the trapezoidal electrodes. Where the top electrode spacing is shorter,the uniaxial strain generated is larger. Therefore, setting different trapezoids can control the rate of strain drop.Skyrmions can even be limited in a strain potential well by setting the top electrodes,if required.

Through the calculation in Fig. 2(a), we determine that the trapezoidal top electrodes can produce a uniaxial strain gradient between the two electrodes. Next, we use the micromagnetic simulation software Mumax3[48]to simulate the N´eel-type skyrmion motion in the Pt/Co/Ta nanostrip driven by solving the Landu–Lifshitz–Gilbert equation[49]

whereYis the Young’s modulus,Uis the applied voltage,tdis the distance between the two top electrodes, andtpis the thickness of the piezoelectric layer.deffis the piezoelectric coefficient,which is given as

wherev=0.3 is Poisson’s ratio. In the simulation,the size of the Pt/Co/Ta nanostrip is 256 nm× 50 nm, the thickness of the Co layer is 1 nm, the grid size is 2 nm× 2 nm× 1 nm,the damping coefficientα=0.1,the saturation magnetostrictionλs=-2×10-5,the saturation magnetizationMs=5.8×105A/m,and the exchange constantA=1.5×10-11J/m. All strain directions are perpendicular to the skyrmion movement direction,that is,the long axis of the nanostrip.

Fig.2. (a)Uniaxial strain distribution on the surface of the piezoelectric layer generated by trapezoidal top electrodes. The color shows the normalized uniaxial strain calculated by COMSOL software. (b) The Ne´el-type skyrmion motion driven by the strain gradient. The magnetization in different directions is indicated by HSL color.

Figure 2(b)shows the N´eel type skyrmion motion driven by the strain gradient. The HSL color in the figure indicates the magnetization in different directions. The uniaxial strain decreases uniformly from 2000 MPa(on the left side of the nanostrip) to 0 (on the right side of the nanostrip). The skyrmion is driven by the strain gradient from the left side to the right side of the nanostrip. The skyrmion moving speed under a uniform strain gradient decreases with the strain. The distance of the first 40-ns movement is almost equivalent to the distance of the subsequent 120-ns movement. After 160 ns,the skyrmion movement tends to stagnate. This shows that the skyrmion moving speed is not only related to the strain gradient but also related to the magnitude of the strain. When the strain is too small,the skyrmion cannot continue to move.

We calculate the influence of the magnitude of the strain on the skyrmion velocity,as shown in Fig.3. We fix the strain gradient to 0.78125 MPa/nm, and make the skyrmion move from the center of the nanostrip to the right. The average velocity of skyrmions within 10 ns is calculated with the strain at the center of the nanostrip from 100 MPa to 1000 MPa. As shown in Fig.3,skyrmion velocity increases linearly with the strain.Therefore,the greater the strain,the faster the skyrmion moves. If the strain is too small,the skyrmion will not be able to move. For our material system,the skyrmion motion has a threshold strain close to 100 MPa. Below this strain level,the skyrmion will stop moving.When the strain is too large(about 1800 MPa), the skyrmion will be “squeezed” by the strain and annihilated. Under the action of the strain gradient, the skyrmion will produce asymmetric deformation, which leads to the motion of the skyrmion. Due to the topological protection of the skyrmion, the skyrmion can basically maintain its shape,moving under certain strains and strain gradient. A certain threshold of the strain and the strain gradient are required for the skyrmion to produce enough deformation for its motion. It can be compared to the ball in Fig.1(a),which explodes under excessive pressure. Therefore, using the strain gradient to drive skyrmions requires the strain not too large to cause the skyrmion to annihilate.

Fig.3. The speed variation of skyrmion as a function of the beginning strain in the middle of Pt/Co/Ta nanostrip as the strain gradient is fixed.

We then calculate the influence of the strain gradient on the skyrmion velocity,as shown in Fig.4.We fix the maximum strain of the nanostrip to 2000 MPa,and calculate the average speed of skyrmion in 10 ns under different strain gradients.Similarly, skyrmion motion requires a strain gradient greater than a threshold, about 0.7 MPa/nm. Below this strain gradient, the skyrmion cannot move. Different from the influence of strain magnitude, the influence of increasing strain gradient on skyrmion velocity is not linear. Although the skyrmion velocity increases with the strain gradient, the ascent speed slows down with the increase of the strain gradient. After the strain gradient increases above 7 MPa/nm, the skyrmion velocity will no longer increase significantly with the strain gradient. Therefore, when the strain gradient is applied to drive skyrmion motion, the energy consumption, efficiency and transmission distance should be considered comprehensively to set the strain gradient reasonably.

The reading of skyrmion can be achieved by constructing a magnetic tunnel junction at the appropriate position.Liet al.recently reported a skyrmion magnetic tunnel junction,which displays an obvious tunnel magnetoresistance signal.[50]Their experiments showed that the skyrmion had a double-layer coupling structure in the tunnel junction and could generate a readable tunnel magnetoresistance signal through the difference in interplane magnetization between the free and reference skyrmion layers.

Since the calculation of micromagnetic simulation is difficult to support the calculation of oversized size, the nanostrips we calculate are at nanometer size and the strain gradient is amplified. It should be pointed out that it is difficult for our electrode to generate a very large strain gradient due to the limitation of the thickness of the piezoelectric layer in the experimental preparation. Therefore, the speed of the skyrmion driven by the strain gradient is significantly lower than that driven by the current. Meanwhile, due to the limitation of electrode size,the range of strain gradient is limited.Therefore, our design is suitable for the local precise motion of skyrmion with low heat loss. A large range of skyrmion motions can be considered by growing magnetic materials on flexible polyimide substrates to produce a large range of strain gradients.[51]

Fig.4. The speed variation of skyrmion as a function of the strain gradient in the Pt/Co/Ta nanostrip as the beginning strain is fixed.

4. Conclusion

We proposed a skyrmion transport method driven by a voltage-generated strain gradient. Through the arrangement of trapezoidal electrodes pair on the piezoelectric layer,a uniform uniaxial strain gradient is generated to the ferromagnetic nanostrip to drive the skyrmion to move. Due to the symmetry of the strain, the skyrmion can move stably along a straight line under strain protection without deviation. The speed of movement increases with the strain intensity and the strain gradient. It is worth mentioning that the strain-gradient induced skyrmion transport speed is not comparable to the current induced skyrmion transport speed. In addition,the architecture is not compatible with modern semiconductor technology. Therefore,our approach is mainly aimed at the insulating skyrmion-hosting materials regardless of their electrical conductivity.

Acknowledgements

Project supported in part by the National Natural Science Foundation of China (Grant No. 61832007), the Natural Science Foundation of Shanxi Province, China (Grant Nos. 2021JM-221 and 2018JM6075), and the Natural Science Basic Research Plan in Shanxi Province of China(Grant No.2020JQ-470).

- Chinese Physics B的其它文章

- A design of resonant cavity with an improved coupling-adjusting mechanism for the W-band EPR spectrometer

- Photoreflectance system based on vacuum ultraviolet laser at 177.3 nm

- Topological photonic states in gyromagnetic photonic crystals:Physics,properties,and applications

- Structure of continuous matrix product operator for transverse field Ising model: An analytic and numerical study

- Riemann–Hilbert approach and N double-pole solutions for a nonlinear Schr¨odinger-type equation

- Diffusion dynamics in branched spherical structure