Enrichment of microplastic pollution by micro-nanobubbles

Jing Wang(王菁) Zihan Wang(王子菡) Fangyuan Pei(裴芳源) and Xingya Wang(王兴亚)

1Key Laboratory of Interfacial Physics and Technology,Shanghai Institute of Applied Physics,

Chinese Academy of Sciences,Shanghai 201800,China

2Shanghai No. 3 Girls’High School,Shanghai 200050,China

3Shanghai Synchrotron Radiation Facility,Shanghai Advanced Research Institute,Chinese Academy of Sciences,Shanghai 201204,China

4School of Physical Science and Technology,Shanghai Tech University,Shanghai 201204,China

5University of Chinese Academy of Sciences,Beijing 100049,China

6East China University of Political Science and Law,Shanghai 201620,China

7University of Shanghai for Science and Technology,Shanghai 200093,China

Microplastic pollution has become a global environmental concern. It has been reported that microplastics are easily accessible to a wide range of aquatic organisms and ultimately enter the human body along the food chain. They pose a severe threat to ecosystems,organisms and even human health due to their durability and persistence. However,how to reduce microplastic pollution still remains a challenge in terms of scientific techniques and policy-making. There is currently still a lack of effective methods for microplastic recycling and removal. Luckily, a new technique, micro-nanobubbles(MNBs), may provide a possible and highly effective method to enrich microplastic pollution: their great advantages[1]include a high specific surface area, long lifetime and ability to adsorb microplastics of the same size and hydrophobicity. Then they further adsorb on larger bubbles such as microbubbles or millimeter bubbles and float to the water surface together. In this study, we present a new method using MNBs to enrich microplastic pollution with high efficiency. Two types of microplastics,millimeter-scale plastic fragments and microplastic particles,were chosen as the model microplastic pollution systems to study the enrichment efficiency of MNBs on microplastics. Results showed that MNBs can efficiently enrich these microplastics. The enrichment efficiency increases with flotation time until a maximum value is reached. It is proved that MNBs not only collect the microplastic pollution but also reduce detergent use in domestic laundry sewage.This is because detergent,as a surfactant,is easily absorbed on the surface of MNBs and can be collected together with the microplastic pollution. Our research has demonstrated that the MNB technique could be promising for use in microplastic recycling and reducing detergent pollution in daily life.

Keywords: microplastics,nanobubbles,enrichment efficiency

1. Introduction

Microplastics are small plastic particles or pieces(dimensions<5 mm) that are usually produced by the degradation of larger plastic debris or by activites of daily life. For example, plastic particles in medicines or toiletries may be released and enter domestic sewage directly through the water treatment system; these then overflow from the sewage treatment plant into the environment without complete removal.[2]Personal cosmetics are another major source of microplastics. Studies have found that all the detergents purchased in stores contain microbeads and microplastic fragments. Shedding of microfibers produced by the interaction between the detergent and the fabric also remarkably increases microplastic pollution. Compared with large plastic waste items, microplastics can easily enter organisms. They can seriously affect and damage the environment as they have a large surface area and high capacity to adsorb pollutants.[3]Due to their extremely tiny size and persistence, microplastics have a long residual time after they enter an organism, thereby causing tremendous damage to the organism.[4]As the particle size is further reduced,microplastics could be transferred into the circulatory system, immune system and even tissue cells through the digestive tract of marine organisms, triggering the inflammatory response of the organism’s immune system.[5]Also,when microplastics enter the marine environment the micro-organisms in the environment could quickly attach to the surface of the microplastics and form a relatively stable biofilm.[6]It is estimated that the microbial population on the surface of microplastics in the ocean is in the ranges of 1×103tons–1.5×104tons.[7]Under the action of ocean currents and tides,marine microorganisms could use these‘floating rafts’ for long-distance migration across the sea, promoting the invasion of alien species.

However, microplastics cannot be recycled by conventional methods due to their extremely small size.Microplastics in the environment are essentially a composite pollutant system with multiple dynamic changes and uneven distribution.Traditional methods of pollutant collection, separation and identification are not suitable for the disposal of microplastics. Therefore,it is very important to find a new technique to reduce these microplastic pollutants.

In recent years a new technique,[8,9]micro-nanobubbles(MNBs), has been utilized in many fields such as nano-cleaning,[10–12]waste-water treatment,[10]mineral flotation,[13]and petroleum recovery.[14]It has been reported that nanoscale gas bubbles have a very long lifetime and could be stable for several hours or days in water. Furthermore,nanobubbles have a larger specific surface area to easily absorb hydrophobic materials, making them useful for mineral separation in froth flotation.[1,15,16]The bridging force induced by nanobubbles can enhance the attraction between fine mineral particles,which brings more particle aggregation and increases the efficiency of flotation.[1,17]Based on the same nanobubble principle used in mineral flotation,they could also be used in the collection of microplastics. Smaller bubbles easily absorb smaller microplastics and larger bubbles drive them to the water surface.[18]It is expected that microplastics could be removed or collected efficiently by MNBs in water.

Here, we designed a series of experiments to study the collection of microplastics by the MNB technique for the first time. Microplastics with different sizes were studied. Conventional air bubbles produced by a flotation machine and nanobubbles in water produced by the bubble generator were used to enrich the millimeter-sized plastic fragments and microplastic particles.Nanoparticle tracking analysis(NTA)was used to measure the concentration and size distribution of the nanobubbles formed by the flotation machine and bubble generator. Laundry sewage was also prepared to study the recycling of microplastic pollution.The change in enrichment efficiency of microplastics over the flotation time was also investigated. We believe that this research will provide a very useful technique to resolve the microplastic pollution and suggests an innovative idea for the recycling of microplastic pollution in domestic sewage.

2. Results and discussion

2.1. Enrichment efficiency of plastics with water with different sized bubbles

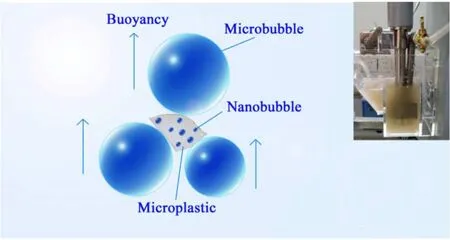

Four different enriching experiments were conducted.They were enriching millimeter-sized plastics with regular bubble water and a mixture of regular bubble water and MNB water, and enriching microplastic particles with regular bubble water and a mixture of regular bubble water and MNB water, respectively. Figure 1 shows a schematic diagram of the flotation principle and the structure of the single-vessel flotation machine. First,microplastics of different sizes(millimeter size plastic sheets and microscale polyethylene particles)were dispersed in tap water and then poured into the cell of the flotation machine. The flotation machine can produce regular bubble water to make microplastics float to the surface of the water. The enriched microplastics were scraped into a beaker. Finally,the collected plastics were dried and weighed.

Fig.1. Schematic diagram of the flotation principle and a picture of the single-vessel flotation machine.

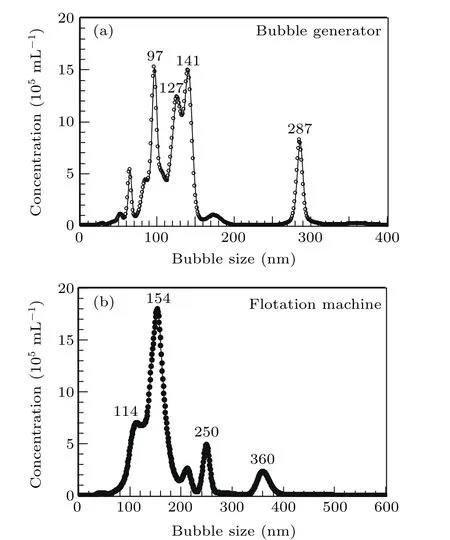

Fig.2.Size distribution of nanobubbles produced by the bubble generator(a)and the flotation machine(b).

In order to know how many nanometer gas bubbles were produced in the flotation machine and bubble generator, we used NTA to measure the concentration and size distribution of the nanobubbles formed in the water. It was found that the size of nanobubbles produced by the MNB generator mainly ranged between 100 nm and 300 nm. The concentration was(1.1±0.1)×108mL-1, as shown in Fig. 2(a). Nanobubbles in the water after the flotation machine had been working for several minutes were also measured. Results showed that the flotation machine could also produce a certain number of nanobubbles. This means that microbubbles and nanobubbles as well as regular-sized bubbles were produced or used during the flotation process. Here,we still called the water produced by the flotation machine‘regular-sized bubble water’in order to distinguish it from nanobubble water formed by the MNB generator.The size range of nanobubbles in regular-sized bubble water was mainly between 100 nm and 400 nm. The total concentration of nanobubbles was(8.2±1.5)×107mL-1,as shown in Fig.2(b).

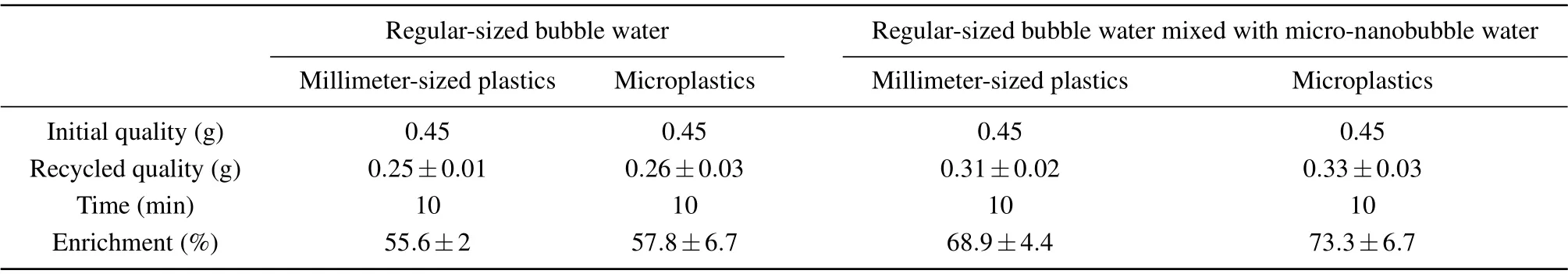

The main results are shown in Table 1. With the same flotation time, the enrichment efficiencies of millimeter-sized plastics and microplastics recycled by regular bubble water were 55.6%±2% and 57.8%±6.7%, respectively. The enrichment efficiency of millimeter-sized plastics and microplastics recycled by mixed regular and MNB water were 68.9%±4.4% and 73.3%±6.7%, respectively. It was found that the enrichment efficiency of microplastics was slightly higher than that of millimeter-sized plastics using both larger and smaller bubbles. The possible reason for this was that some nanobubbles also were produced in regular bubble water as shown in Fig. 2(b); they adsorbed on the surface of the microplastics as a liquid bridge between microplastics and ordinary bubbles and enhanced the rise of microplastics to the surface of the water.[19]The specific surface area of microplastics is larger than that of millimetersized plastics. There are more nanobubbles absorbed on the surface of microplastics per unit volume; this also promotes the rising of microplastics to the water surface.[20]It was also found that by adding nanobubble water to regular bubble water the enrichment efficiency of microplastics was enhanced, proving that the existence of nanobubbles promotes the recycling of microplastics.

Table 1. The recycling efficiency of different size bubbles for the same flotation time.

2.2. Enrichment efficiency of microplastics with different flotation times

In order to know the efficiency of enrichment of microplastics for different flotation times, micron-sized polyethylene particles were used as study samples. A mixture of regular-sized bubble water and MNB water was used in this experiment. Typical results are shown in Fig. 3. The enrichment efficiency of polyethylene particles treated for 10 min,12 min, 14 min, 16 min, 18 min, and 20 min in the flotation machine was 2.8%, 6.7%, 14.3%, 61.7%, 61.9%, and 62.1%,respectively.The enrichment efficiency increased significantly with increasing flotation time and reached its maximum value after 16 min.

Fig.3. The influence of different flotation times on the enrichment efficiency of microplastics.

2.3. Recycling of microplastics from laundry sewage using MNBs

It has been found that clothes washed with detergent produce 86% more microfibers than clothes washed with pure water[21]because detergent makes the fibers loosen and facilitates cleaning. During the cleaning process, numerous small fibers fall off the fabric and drain into the waste water from the washing machine.[22,23]It has been estimated that synthetic microfibers account for 35%of plastic waste.[20]Therefore, we designed an experiment to study the recycling of microplastics from laundry sewage using MNBs. Laundry sewage was prepared with a straight-tube washing machine after cleaning polyester fiber clothes and cotton lint. Then we treated the laundry sewage in a flotation machine. As mentioned in the part of experiments, MNBs can be produced by the flotation machine at the same time. Those MNBs could produce more foam during the flotation (Fig. 4(b), left picture), and much foam was produced during the flotation process.These foams were promoted by residual washing powder in the sewage. Actually, the foam together with microplastic pollution was floated by the bubbles. Figure 4(b) shows the laundry sewage before and after 2 min flotation. It is clear that the treated water appears much cleaner than before the treatment. It should be noted that residual detergents were also removed by the MNBs.

In order to study the components of microplastic pollution recycled from laundry sewage, microplastics recycled from laundry sewage were dried and measured by infrared spectroscopy(IR).Figure 5 shows the IR spectra of microplastics recycled from laundry sewage. There is an obvious composite peak appearing near 600 cm-1, which is caused by C–Cl stretching at 616 cm-1,and a composite peak near 1400 cm-1,which is caused by CH2bending at 1427 cm-1. These results indicate that the microplastics may contain polyvinyl chloride(PVC). The CH2bending at 1451 cm-1, the aromatic ring stretching and the C–H stretching at 2847 cm-1show that the microplastics may include polystyrene (PS). C–O stretching 1094 cm-1also indicates that the microplastics may contain polyethylene terephthalate(PET).The IR results suggest that the recycled samples were composed of PVC,PS and PET.[15]

Fig. 4. (a) Showing laundry sewage being poured into the flotation vessel.(b) The right and left vessels show laundry sewage before (right) and after(left)treatment with the flotation machine using regular-sized bubbles.

2.4. Influence of different flotation times on the enrichment of microplastics in laundry sewage

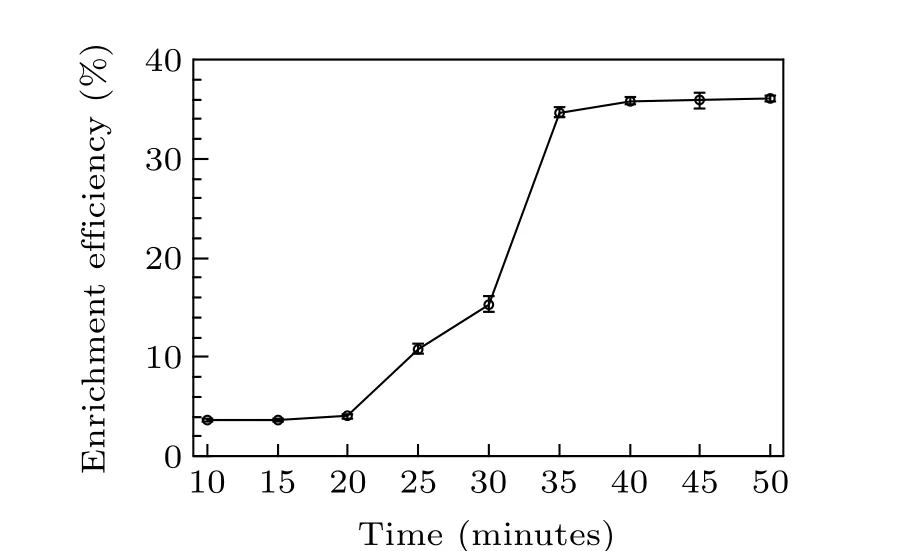

Next, it is necessary to study the influence of different flotation times on the recycling of microplastics in laundry sewage. In order to promote accuracy, we filtered the laundry sewage with a 220 nm pore size filter to remove large particles and flocs. Different flotation times were chosen, as shown in Fig. 6. Results indicated that the enrichment efficiency with flotation times of 10 min,15 min,20 min,25 min,30 min, 35 min, 40 min, 45 min, and 50 min were 3.67%,3.61%, 4.02%, 10.81%, 15.32%, 34.64%, 35.85%, 35.91%,and 36.02%, respectively. It is clear that the enrichment efficiency gradually increases slowly at the beginning then increases rapidly from 25 to 35 mins until finally reaching a maximum. For flotation times longer than 40 min the enrichment efficiency no longer changed significantly.

Fig.6.The effect of flotation time on the enrichment efficiency of microplastic particles in laundry sewage.

2.5. Possible mechanism for enriching microplastics using MNBs

As shown in the above results,the enrichment efficiency of microplastics could be increased remarkably by using MNBs. However,there were some differences when we used different sized bubbles. Generally, the addition of nanobubble water gave a higher enrichment efficiency than a system with just large bubbles. The possible reason for this is that nanoscale gas bubbles have a large specific surface area and high stability. They can easily combine with microplastic particles of the same size and hydrophobicity. Then they further absorb on larger bubbles such as microbubbles or millimeter bubbles and float on the water surface together. Thus,the synergistic effect of nanobubbles and microbubbles further enhances the efficiency of microplastic particle enrichment.Furthermore, this efficiency increases with flotation time and reaches a maximum value. Another advantage of using MNBs is that they can reduce pollution by detergents left in laundry sewage.This is because detergent,as a surfactant,is easily absorbed on the surface of MNBs and can be collected together with microplastic pollution. Therefore,based on the flotation technique and the characteristics of MNBs, this may provide a high efficiency,green environmental protection technique to remove microplastics in water.

3. Experiment

3.1. Materials

3.1.1. Flotation experiment

The flotation machine was purchased from the Jilin Prospector Machinery Factory (XFDVI model, single vessel)to carry out the flotation experiments. This flotation machine mainly consists of a flotation vessel,stirring system,gas intake part,scraper part and electric control part. When the rotor rotates,the centrifugal force throws the liquid outwards,forming a negative pressure. Meanwhile,air bubbles are generated by the shear force of the rotor blades and rise to the liquid surface;they are then scraped out by the scraper together with recycled microplastics. In our experiments, the spindle stirring speed was about 1990 rpm and the airflow rate was kept constant at 600 m3·h-1. The suspension was then shaken for about 1 min and settled for 5 min.

3.1.2. Sample preparation

In the experiments, three kinds of microplastics were chosen as experimental samples(millimetersized plastics,micrometersized plastics and laundry sewage). Millimeter-sized samples were prepared by cutting plastic bags into fragments with sizes smaller than 5 mm, as shown in Fig. S1(a).Micrometer-sized samples were polyethylene particles purchased from Sigma–Alrich with an average size of about 1 μm,as shown in Fig.S1(c). The plastic samples were mixed with MNB water or tap water and stirred for about 10 min (see Figs.S1(b)and S1(d)).

Laundry sewage was obtained from a straight-tube washing machine as it cleaned clothes made of polyester fiber and cotton lint. About 20 g of laundry detergent was used in 18 L water for the cleaning.

3.2. Generation of nanobubbles in water

A MNB generator(purchased from Hangzhou Xiyue New Material Technology Co.,Ltd)was used to produce MNB water.The water intake of the MNB generator was connected to a water tap and clean glassware was placed at the outlet to hold the MNB water. The MNB water was quickly produced once the generator was opened. MNBs could also be generated using the flotation machine. Before the machine was operated,the machine vessel was first cleaned for about 5 min in order to remove any pollution that might exist in the machine. Then the floatation tank was filled with tap water and the switch was turned on for several minutes. During this process,MNBs were produced and measured quickly by NTA. Each experiment was repeated at least three times.

3.3. NTA characterization

The concentration and size distribution of the nanobubbles formed in water were measured by NTA. This was performed using a Malvern Nano-Sight NS300 Instrument operating in scatter mode using a 405 nm laser at 65 mW power.It was equipped with a 20× objective lens and a high-speed camera. The temperature was held constant by the apparatus at 293 K for all experiments. Each result was gathered from an average of five measurements, and each movie lasted for 60 s, captured at 25 frames/s. The camera level was usually set at 10,the threshold was set at 3 and the solution viscosity was 1 cP.The optical field of view was fixed(at approximately 100 μm×80 m) and the depth of the illuminating beam was approximately 10 μm. Here, the size of an individual particle(nanobubble)could be calculated from its diffusion due to Brownian motion. NanoSight NTA 3.2 software was used to calculate the position of each visible particle across the frames of the videos. Each experiment was repeated five times independently.

3.4. IR spectroscopy

IR spectroscopy (Perkin–Elmer) was used to check whether recycled samples obtained from laundry sewage contained microplastic components in the 4000 cm-1–400 cm-1spectral range. Before the measurements, dry potassium bromide was added to the flotation products as a diluent. They were than whisked together until they were well combined.The sample was ground in an agate mortar until there was no graininess remaining (mid-infrared scattering can occur when particles are between 2.5 μm and 25 μm in size). Then the sample was put into a special mould. The mixture was smoothed with a flat spatula and a pressure machine used to press it into a thin slice for measurement.Without the smoothing step the sample would be partially transparent.

4. Conclusion and perspectives

In summary,for the first time a MNB technique was used to recycle microplastic pollution. Two types of microplastics,millimeter-scale plastic fragments and microplastic particles,were chosen as the model systems for microplastic pollution to study the enrichment efficiency of microplastics using MNBs of different sizes. We also prepared laundry sewage to further investigate the effect of MNBs on the recycling of microplastic pollution in it. NTA was utilized to characterize the concentration and size distribution of nanobubbles in water. During the flotation process, MNBs could also be produced and water with more nanobubbles can enhance the enrichment efficiency of millimeter scale and microplastic particles. The recycling efficiency of microplastic pollution increased with flotation time until it reached a maximum value.Specifically, for the system of microplastic particles, the enrichment efficiency quickly increased to a maximum of about 62%for 16 min floatation. For the system of laundry sewage,the enrichment efficiency gradually increased at first,then become fast from 25 to 35 mins,finally reaching a maximum of about 36%efficiency. We found that for the system of laundry sewage the enrichment efficiency was lower and more flotation time was needed to reach the maximum value than with a pure microplastic particle system.This may be due to the small size and low concentration of microplastic pollution in everyday laundry sewage. The principle of enrichment of microplastic pollution by MNB water could be described as follows. Micro and nanometer-scale gas bubbles have a very large specific surface area and also easily absorb hydrophobic plastics.Nanometer-scale gas bubbles first absorb on microscale plastic particles or sheets,and then large bubbles produced during the flotation process help float microplastics and MNBs to the surface together, enriching the surface with microplastics. More interestingly,the use of MNB water can also reduce the detergent left in sewage and decrease environmental pollution. Our study provides an effective method for enriching microplastic pollution and also presents an innovative idea for the reduction of microplastic pollution in domestic sewage. Further research is very necessary for finding the best use of the MNB technique in disposing of microplastic pollution in the future.

Acknowledgments

Project supported by the National Natural Science Foundation of China(Grant Nos.11874379 and 11575281)and the Knowledge Innovation Program of the Chinese Academy of Sciences(Grant No.QYZDJ-SSW-SLH019).

- Chinese Physics B的其它文章

- A design of resonant cavity with an improved coupling-adjusting mechanism for the W-band EPR spectrometer

- Photoreflectance system based on vacuum ultraviolet laser at 177.3 nm

- Topological photonic states in gyromagnetic photonic crystals:Physics,properties,and applications

- Structure of continuous matrix product operator for transverse field Ising model: An analytic and numerical study

- Riemann–Hilbert approach and N double-pole solutions for a nonlinear Schr¨odinger-type equation

- Diffusion dynamics in branched spherical structure