受猪笼草启发的多孔微腔低冰黏附防除冰表面

向科峰,尹欢,宋岳干,杨益,李国强,赖林

受猪笼草启发的多孔微腔低冰黏附防除冰表面

向科峰,尹欢,宋岳干*,杨益,李国强,赖林

(西南科技大学 制造科学与工程学院,四川 绵阳 621010)

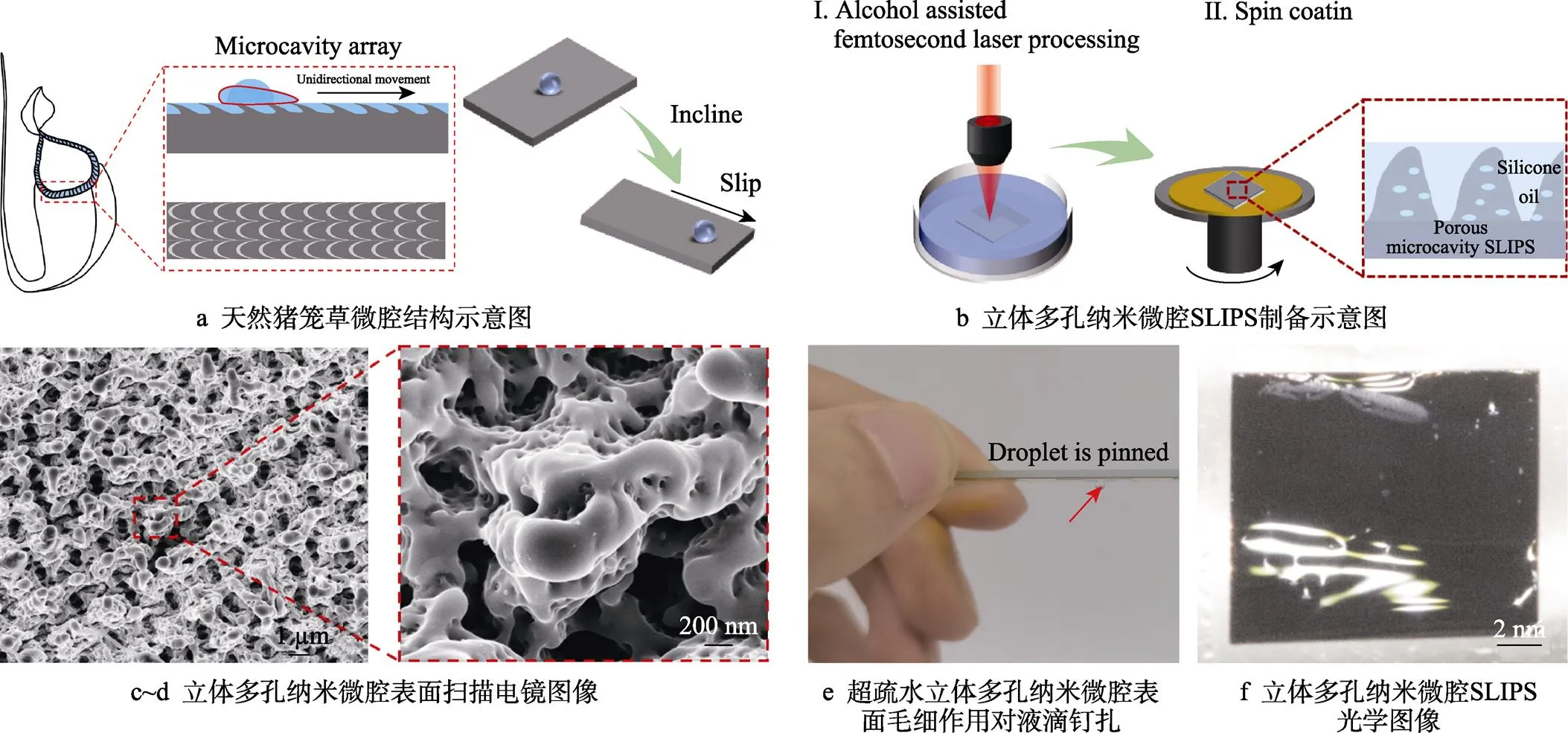

提高光滑液体注入表面(SLIPS)的防/除冰耐用性。将镍箔完全浸没在无水乙醇中,使用飞秒激光照射无水乙醇环境中的镍箔表面诱导出立体多孔纳米微腔阵列结构,并使用氟硅烷改性增加表面对硅油的亲和力,最后用50 cSt的硅油旋涂在改性后的表面上。通过扫描电镜和光学显微镜对立体多孔纳米微腔结构进行形貌分析,并通过延缓结冰试验、冰黏附强度测试和高温蒸发试验,分别评价该SLIPS的延缓结冰性能、冰黏附强度和防除冰耐用性。在立体多孔纳米微腔结构的毛细作用下,具有亲油憎水性的立体多孔纳米微腔表面上的蒸馏水滴也会被钉扎。相比非结构化表面,该SLIPS将延缓结冰时间提升了2.8倍,同时,在低温高湿度环境中,实现了冷凝水的自去除。在80 ℃高温环境下的蒸发10 min后进行结冰/除冰操作,10个周期后,该SLIPS的接触角(CA)为110°,滑动角(SA)为8.5°,以及冰黏附强度参数(ice)为3.6 kPa。利用飞秒激光加工无水乙醇环境中的镍箔表面生成的立体纳米多孔微腔阵列结构能够减少SLIPS表面的润滑剂损失,可有效提高防除冰SLIPS的耐用性。

仿生;飞秒激光直写;纳米微腔结构;SLIPS;低冰黏附;防冰;除冰

霜冻是自然界中普遍存在且常给人类社会造成巨大危害的自然现象,充分掌握和揭示固体表面积冰现象的机理是近代社会面临的巨大挑战[1-3]。传统的防除冰方法主要包括加热除冰,机械除冰以及一些化学除冰方法[4-6],这些主动除冰方法普遍受到除冰效率低,破坏生态环境等弊端的限制。因此,被动防除冰技术的研究迫在眉睫。

被动除冰方法中,超疏水表面(SHS)因其卓越的防污[7]和自清洁性能[8]而受到广泛关注[9-10]。SHS是通过减少表面杂质来抑制冰晶异相成核,实现防除冰目的。此外,SHS多层级微/纳结构可减少液滴与表面的接触面积,从而提高冰晶成核势垒[11-13]。然而,在高湿度条件下,未及时去除的液滴会在SHS上形成冰核,并在微纳结构中发散,延伸到狭隙中,使得SHS与冰互锁,最终导致SHS防冰性能失效[14]。由此可见,SHS并不是长期防结冰的完美策略。为了克服高湿条件下SHS防冰性能失效的缺陷,SLIPS通过将润滑液注入基底,在冰和基底之间形成润滑剂层来防止冰积聚[15-18]。低结冰点的润滑层延迟了冰的成核时间,并在最大限度上减少了粗糙表面上的冰与固体表面的接触面积,最终实现防冰性能。然而,进一步研究表明,润滑液在结冰/除冰循环过程中容易损失,导致SLIPS性能失效。因此,如何提高SLIPS的稳定性是一大挑战。

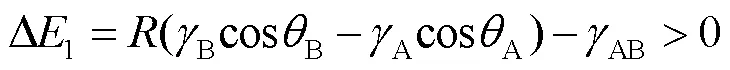

猪笼草瓶口具有多梯度楔角和锐利边缘的不对称拱形微腔结构,此外,该结构中还注满了腺体分泌的润滑液,用于减小摩擦阻力[19]。该结构不仅能实现液滴单向运输[20],还可使润滑液稳定保留在微腔中,实现长期捕获昆虫。受猪笼草瓶口多孔微腔注液表面的启发,本文采用酒精辅助超快飞秒激光直写技术在镍箔表面加工具有立体纳米孔洞的微腔阵列结构,再将50 cSt的硅油均匀旋涂在氟化后的表面制备SLIPS。该表面独有的立体纳米微腔结构赋予了表面卓越的毛细力,极大地增强了该SLIPS的稳定性。本文在每一次结冰/除冰后,将立体多孔纳米微腔SLIPS置于80 ℃环境中蒸发10 min,10个周期后,其CA、SA以及ice依旧保持稳定。此外,即使在高湿度条件下,该SLIPS可以有效去除冷凝水分从而抑制冰/霜的积聚。

1 试验

1.1 试剂与仪器

试剂:1H,1H,2H,2H-全氟癸基三乙氧基硅烷(C16F17H19O3Si),上海阿拉丁生化科技有限公司;无水乙醇(CH3CH2OH),成都金山化学试剂有限公司;蒸馏水,实验室自制。试验基底材料为镍箔。

仪器:Sosltice Ace型飞秒激光一体化系统,美国NWEPORT公司;CY-SPC4-A匀胶机,郑州成越科学仪器有限公司;Ultra 55型场发射扫描电子显微镜系统,德国Carl Zeiss NTS GmbH公司; EOS-750D型数码照相机,佳能(中国)有限公司;SDC-350型接触角测量仪,东莞晟鼎精密仪器有限公司;HA- JS826A型超声波加湿器,中山市浩奇电器有限公司;LJ800-012型数显推拉力计,南京苏测计量仪器有限公司;实验室自主搭建四核心环境封闭制冷系统。

1.2 酒精辅助飞秒激光加工技术一步诱导生成立体纳米微腔结构

天然猪笼草微腔结构与功能示意图如图1a所示,受它启发的仿生立体多孔SLIPS制备过程如图1b所示。首先,将镍箔(10 mm×10 mm)放入无水乙醇中使用超声波清洗仪清洗10 min,再放入80 ℃干燥箱中干燥10 min。将干燥后的镍箔固定在皮氏培养皿中并加入无水乙醇,使无水乙醇没过镍箔表面。采用飞秒激光直写扫描系统加工浸没在无水乙醇中的镍箔表面。通过SCANLAB LaserDesk软件绘制相互垂直且间隔25 μm的网格草图。加工时采取的激光

脉冲为高斯光束,中心波长为800 nm,脉冲宽度为104 fs,1 kHz重复频率,使用功率为80 mW,扫描速度为0.001 m/s。酒精辅助飞秒激光加工镍箔后表面微结构如图1c~d所示。为了增加表面对硅油的亲和力,对激光加工后的样品使用氟硅烷改性。将加工后的镍箔放入体积比为1∶50的氟硅烷酒精溶液中浸泡2 h,取出后在80 ℃的干燥箱中干燥1 h。此时表面表现出卓越的毛细作用,能钉扎与表面具有排斥作用的液滴(图1e)。最后在匀胶机上旋涂50 cSt的硅油,使用转速为500 r/s,时间为1 min,样品如图1f所示。为了确保立体多孔纳米微腔表面优先被润滑液润湿,应满足[15]:

表1中,A、B分别是蒸馏水和硅油的表面张力,AB是蒸馏水和硅油交接面的表面张力,A、B分别是蒸馏水和硅油在氟化改性后立体多孔纳米微腔镍箔表面上的接触角,是立体多孔纳米微腔表面实际面积和投影面积的比值。带入表1的数据计算出∆1> 0,∆2>0,满足表面优先被硅油浸没。

1.3 润湿性能测试

将样品固定在接触角测量仪系统的样品台上,通过注射系统在样品表面上滴入5 μL的水滴,测量此时接触角的大小。再通过三维移动平台使样品倾斜一定角度,测量液滴在样品表面发生滑动时的临界倾斜角,即滚动角。所有接触角和滚动角均为同一样品不同位置3次测试值的平均值。

1.4 防除冰测试

延迟结冰测试:将所制备的SLIPS放置在环境封闭制冷系统的四核心制冷台上,在SLIPS上滴入8 μL液滴,通过数码相机记录结冰过程并统计结冰时间。低温高湿度环境下的抗冰测试:将SLIPS和SHS放入冰柜中(‒10 ℃),使用加湿器增加湿度,并通过数码相机记录各表面冻结过程。冰黏附力测试:在四核心制冷台上放置所制备的SLIPS,同时在表面上放置5 mm×5 mm×50 mm的冰柱模型并注满蒸馏水冷冻12 h。通过匀速推动拉力计推倒完全冻结后的冰柱并实时记录推力,根据压力公式(ice,其中是推力峰值力,是冰柱的有效横截面积)计算冰黏附强度ice。每个样品报告的值都是取3个样品的平均值。

图1 仿生SLIPS制备与表征

表1 界面优先润湿的计算数据

Tab.1 Calculation data of preferential wetting of interface

2 结果与讨论

2.1 立体多孔纳米微腔SLIPS形貌表征分析

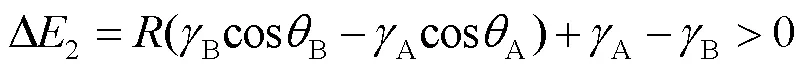

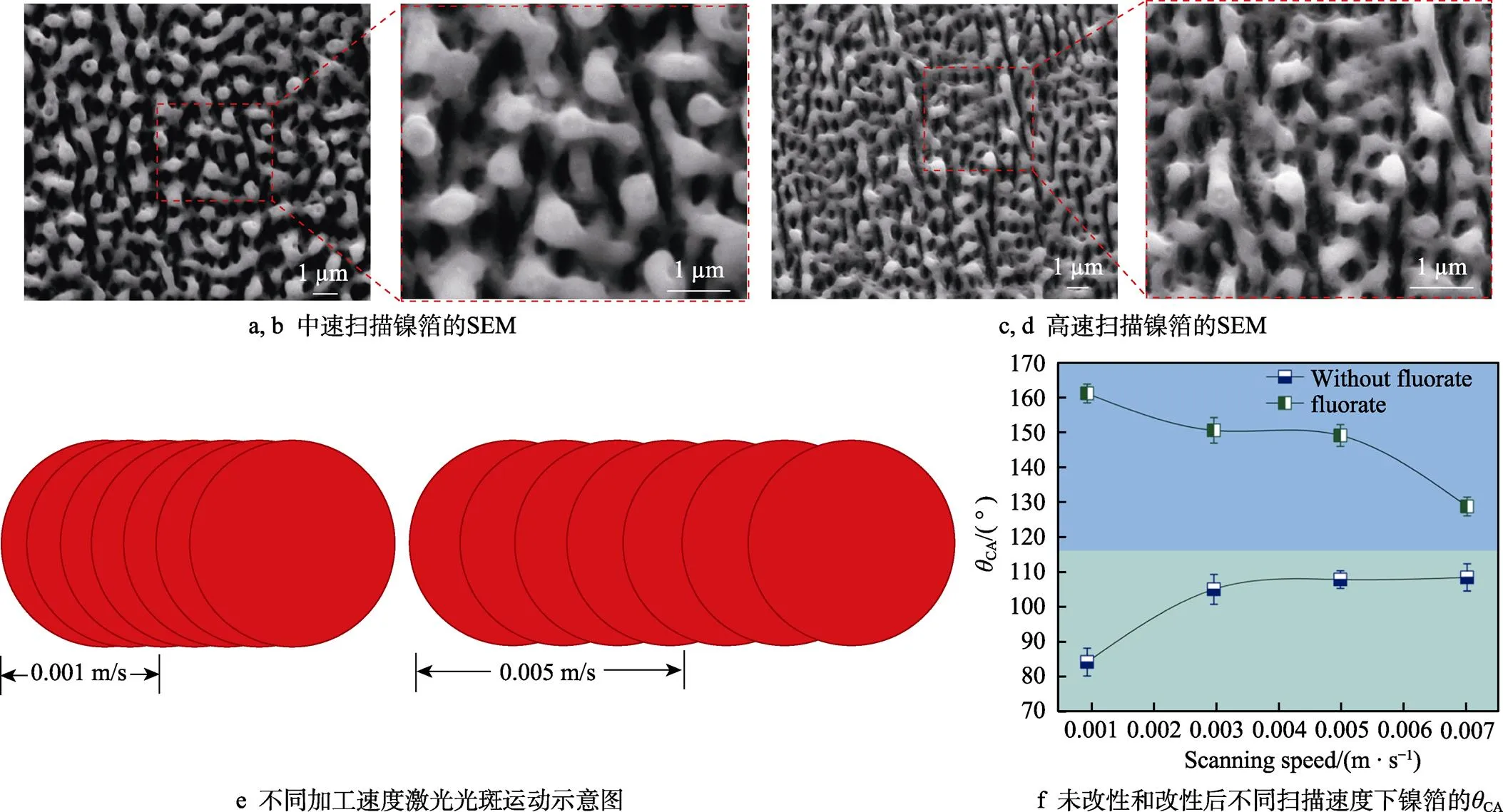

为了制备具有高毛细作用的表面结构,需要在表面使用激光诱导出密集的纳米孔洞。利用无水乙醇营造的液体环境增强了激光诱导等离子体、声压、以及冲击波和爆炸性汽化,促使激光对基底加工附近会产生过热物质和瞬间高压区,并将周围液体带入到超临界状态[21-24]。金属镍的熔体层在高冲击和爆炸性汽化显现的相互作用下,其形态受到剧烈扰动,冷却重铸后形成纳米微腔结构[21]。立体纳米微腔结构的形貌取决于激光束的脉冲能量和辐照时间。在激光功率80 mW的前提下,分别用0.001、0.003、0.007 m/s的速度对浸没在无水乙醇下的镍箔表面进行扫描,其扫描电镜图像(SEM)分别如图1c~d、图2a~b和图2c~d所示。通过增加激光扫描速度,纳米孔洞的平均直径在增加,且数目逐渐减少,结构也变得更加简单。这是由于低速扫描能产生更加密集的冲击波和爆炸汽化现象,使得扫描速度越快的镍箔表面纳米孔洞更少(图2e)。低速诱导的立体纳米多孔结构对液滴有着高黏附性,即便是使用低表面能的氟硅烷改性后仍然表现出“玫瑰花效应”,这使得表面能更低的硅油能够更好地储藏在纳米微腔结构中,实现SLIPS的高稳定。

图2 不同扫描速度下镍箔的SEM和润湿性

2.2 润湿性分析

未加工的镍箔表面CA=64°,通过酒精辅助激光低速扫描后镍箔表面CA=84°,氟硅烷改性后的CA=163°。未改性的结构化镍箔表面对水滴有着毛细作用,使得未改性结构化表面CA比非结构化镍箔表面仅大20°。随着激光扫描速度的增加,改性后的样品CA呈现出降低趋势(图2f)。这是由于CA由表面粗糙度和表面能共同决定,低速扫描能使激光作用的局部区域产生更加剧烈的爆炸和气化现象,熔融的镍重铸生成的纳米孔洞的数量也就更多,粗糙度得到进一步增加,因此改性后的CA也就越大。

从不同样品的CA不难看出低速扫描能诱导出数目更多更加密集的立体纳米孔洞结构,并在宏观展现出对液体的高黏附性,因此,低速扫描的镍箔表面能更好地维持SLIPS的稳定性。

2.3 防/除冰性能分析

针对结冰现象的不同阶段,样品防/疏冰的性能主要通过两个指标进行评价:冰成核延迟时间和表面冰黏附强度ice。防冰是指延长过冷液滴结冰时间,使过冷液滴在完全冻结前在外力作用迅速脱离表面,达到防冰目的。疏冰是指冰黏附强度小于100 kPa,当冰黏附强度小于100 kPa时,表面能在震动和风等外力作用下被动去除。

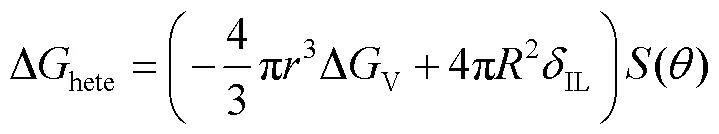

如图3a所示,非结构化镍箔表面延缓结冰时长为240 s,而SHS和立体多孔微腔SLIPS延缓结冰时长分别为667 s和677 s,试验结果表明该SLIPS延缓结冰时间是非结构化表面的2.8倍。此外,SHS和SLIPS均能有效延缓结冰时间,达到防冰目的(图3b)。但是,不同表面的结冰时间有很大差异,造成这种差异的机理可以用热力学方程来解释。SLIPS上形成冰主要是一个均相成核过程,其成核自由能垒(∆homo)可由公式(3)计算[25-27]。而非结构化表面和SHS主要是异相成核,其冰核自由能壁垒(∆hete)可由公式(4)~(5)计算。

式中:是成核半径,是CA,IL是晶核和润滑油之间的界面能,ΔV是凝固驱动力,()是的单调递增函数。在成核过程中,非结构化表面和SHS水接触角分别为64°、163°,比值(∆hete/∆homo)分别为0.192和0.988,且0.192<0.998,理论计算与试验结果一致。此外,冷凝水在蒸汽压力梯度的影响下不断汇聚并释放表面能,由于SLIPS具有较低的摩擦阻力,液滴在汇聚变大过程中自发向边缘移动,实现了冷凝水的自去除(图3a)。

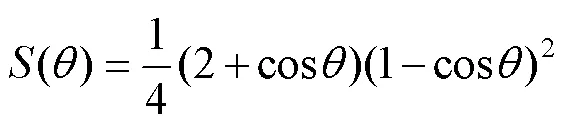

为了进一步比较SHS和SLIPS的防冰性能,将SHS和SLIPS水平放置于环境温度‒10 ℃的冰柜中,并通过超声波加湿器加湿营造低温高湿环境。在室温且非高湿环境中时,SHS表面的液滴处于Cassie状态[28],此时空气被困在水滴下的微/纳结构中形成气垫,气垫大大减少了液滴和表面的接触面积,表现出卓越疏水性。当环境温度为‒10 ℃且高湿度时,SHS表面上液滴的接触角显著降低,如图4a所示,此时液滴处于Wenzel状态[29]。造成Cassie状态转变为Wenzel状态的原因是痕量水在微/纳结构的缝隙中凝结成更小的液滴,此时由于空气垫被微液滴所取代导致表面疏水性降低[30-32]。由于Wenzel状态恢复到Cassie状态需要突破较大的能量势垒,因此Wenzel状态无法自发恢复到Cassie状态[33-36],这将大大削弱SHS的防冰能力。微/纳结构中的微液滴在持续的低温下成核冻结,并在缝隙中发散延展[37-38],直至整个表面完全冻结(图4a)。因此,在低温高湿环境下,具有微/纳结构的SHS防冰性能被大大削弱。在温度极低的情况下,SLIPS上也会发生液滴冻结现象[39],并且每个冷凝液滴的生长和聚结导致液滴尺寸随着时间的推移逐渐增加,如图4b所示。图4b展示了SLIPS在低温高湿度环境中的结冰情况,迎风口在高湿度冷空气的侵袭下,SLIPS的左侧率先出现冷凝液滴,并不断往右侧生长。215 s时,SHS上液滴和冰霜的覆盖率达到了近乎100%,而此时SLIPS上的液滴-冰霜覆盖率仅16.8%。417 s时,SHS表面被完全冻结,此时SLIPS表面液滴-冰霜覆盖率为71.2%。在极端条件下(低温高湿度),SHS和SLIPS表面都无法避免冻结,但SLIPS在极端环境下的抗冰能力明显优于SHS。

SHS和SLIPS都能在一定程度上延缓结冰,但无法完全扼制结冰现象的发生,因此衡量表面的抗冰性能还要考虑液滴冻结之后冰对表面的黏附强度,即ice。在‒10 ℃的环境温度下使用拉力计测试推倒SLIPS上的冰柱,如图5a所示。冰黏附强度的计算公式为:

式中:τice为冰黏附强度,F为拉力计所测试的推力峰值,A为SLIPS和冰柱的接触面积。

图4 低温高湿环境下的SHS(a)和SLIPS(b)

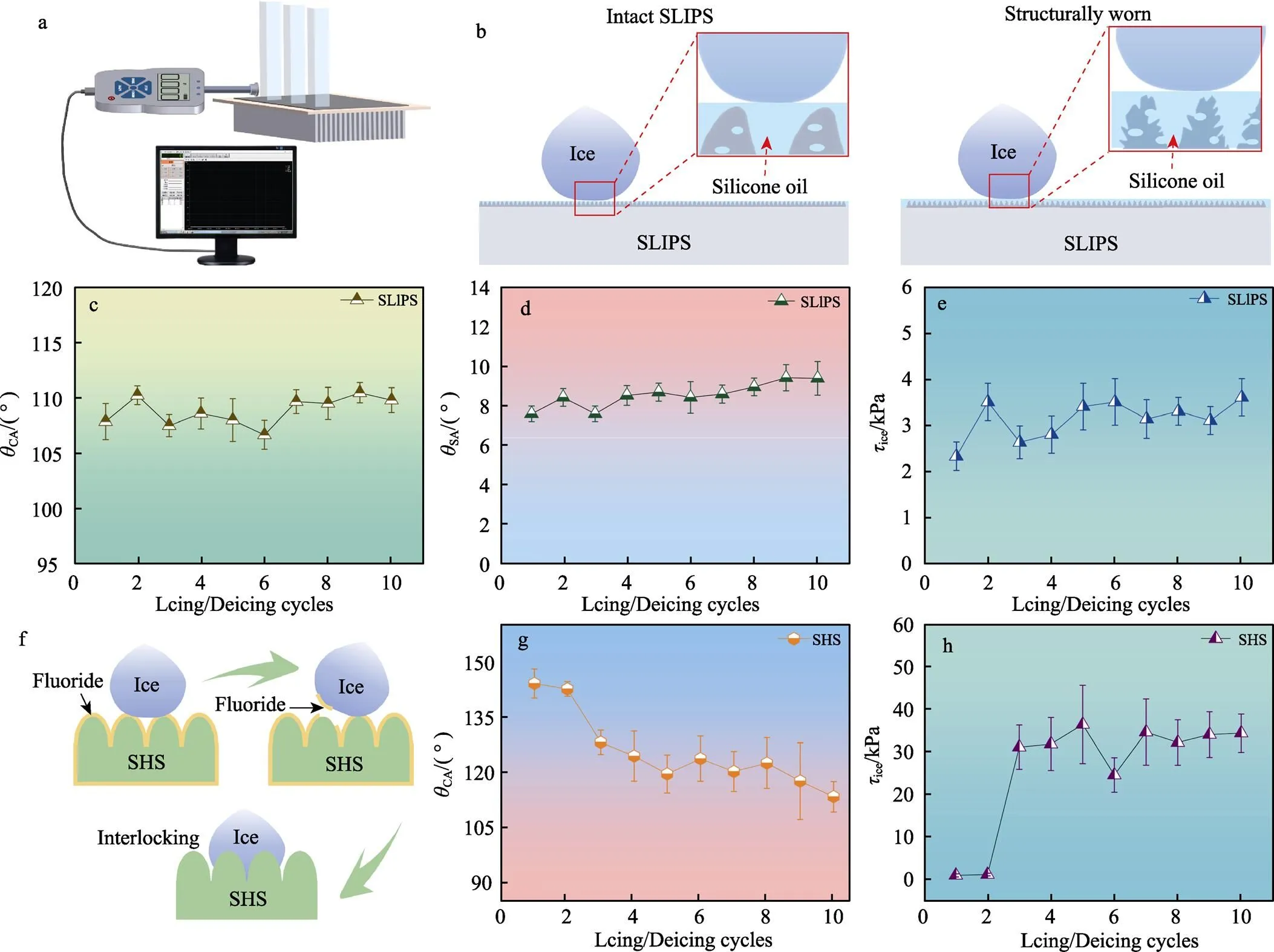

图5 SLIPS稳定性分析:a)冰黏附力测试装置示意图;b)SLIPS自修复示意图;c~d)分别为结冰/除冰10个循环周期内SLIPS的θCA、θSA和τice变化;f)SHS丧失超疏水性示意图;g~h)分别为结冰/除冰10个循环周期内SHS的θCA变化和τice变化

SLIPS的微/纳结构在除冰过程中有所损坏,但是,残破的立体纳米微腔结构变得更加粗糙,孔洞中的硅油再次释放,能填补进硅油缺失区域(图5b)从而继续维持表面功能。图5c~e展示了SLIPS在80 ℃高温下蒸发10 min后进行结冰/除冰循环试验10个周期内的CA、SA以及ice变化。在结冰/除冰循环的10个周期内,SLIPS的CA和SA保持相对稳定(图5c~d),CA和SA分别上升了2°和1.8°。经过公式(6)计算,SLIPS在第1次除冰时的冰黏附强度为2.4 kPa,此时的SHS冰黏附强度仅1.0 kPa。但是,在结冰/除冰的第3个周期时,SHS的冰黏附强度急剧增加,突破到了31.1 kPa,并且没有降低的趋势。造成SHS冰黏附强度激增的原因是在除冰过程中,SHS的表面成分和结构不可避免地遭到了破坏,多分子层的低表面能氟化物随着冰的去除而被去除,并且脆弱的微纳结构也遭到破坏(图5f),使得SHS由超疏水变为疏水(HS),表面液滴状态由Cassie状态变为Wenzel状态。此外,液滴的接触角也由最初的160.9°急剧下降到127.9°(图5g),液滴被牢牢锁在SHS上无法滚落,使其冻结后与SHS互锁造成冰黏附强度急剧上升(图5h)。该SLIPS独特的结构优势使得它的防/除冰性能比传统SHS更加出色,在除冰10次后,SLIPS的冰黏附强度为3.6 kPa,比SHS的冰黏附强度小了1个量级。该SLIPS低冰黏附和长期耐用的特点,使其在防/除冰领域具有极大的应用潜力。

3 结论

本文通过无水乙醇辅助飞秒激光加工的方法,在镍箔表面制备了立体多孔纳米微腔阵列结构,再使用50 cSt的硅油做润滑液,制备了SLIPS。在立体多孔纳米微腔结构的强毛细作用下,增强了表面对润滑液的亲和作用和贮存作用,改善了SLIPS润滑剂易损失的缺陷。在结冰/除冰循环周期中,将SLIPS放入到80 ℃高温环境蒸发10 min后进行结冰/除冰试验,10个周期后,SLIPS的CA=110°,SA=8.5°,并且冰黏附强度仅3.6 kPa。该SLIPS具有稳定的疏冰性能,在防结霜冰领域具有广阔的应用前景。

[1] YANG Si-yan, WU Chen-yang, ZHAO Guan-lei, et al. Condensation Frosting and Passive Anti-Frosting[J]. Cell Reports Physical Science, 2021, 2(7): 100474.

[2] LO C W, SAHOO V, LU Ming-chang. Control of Ice Formation[J]. ACS Nano, 2017, 11(3): 2665-2674.

[3] LI Qi, GUO Zhi-guang. Fundamentals of Icing and Common Strategies for Designing Biomimetic Anti-Icing Surfaces[J]. Journal of Materials Chemistry A, 2018, 6(28): 13549-13581.

[4] CHEN Feng-chen, SU Xin, YE Qing, et al. Experimental Investigation of Concrete Runway Snow Melting Utilizing Heat Pipe Technology[J]. The Scientific World Journal, 2018, 2018: 1-6.

[5] WANG Feng, ZHUO Yi-zhi, HE Zhi-wei, et al. Dynamic Anti-Icing Surfaces (DAIS)[J]. Advanced Science, 2021, 8(21): 2101163-2101163..

[6] HONARVAR NAZARI M, MOUSAVI S Z, POTAPOVA A, et al. Toxicological Impacts of Roadway Deicers on Aquatic Resources and Human Health: A Review[J]. Water Environment Research: a Research Publication of the Water Environment Federation, 2021, 93(10): 1855-1881.

[7] RAGESH P, GANESH V A, NAIR S V, et al. A Review on self-Cleaning and Multifunctional Materials[J]. Journal of Materials Chemistry A, 2014, 2(36): 14773-14797.

[8] FU Yu-chen, JIANG Jing-xian, ZHANG Qing-hua, et al. Robust Liquid-Repellent Coatings Based on Polymer Nanoparticles with Excellent Self-Cleaning and Antibacterial Performances[J]. Journal of Materials Chemistry A, 2017, 5(1): 275-284.

[9] CHENG Tian-tian, HE Ren, ZHANG Qing-hua, et al. Magnetic Particle-Based Super-Hydrophobic Coatings with Excellent Anti-Icing and Thermoresponsive Deicing Performance[J]. Journal of Materials Chemistry A, 2015, 3(43): 21637-21646.

[10] 詹晓力, 金碧玉, 张庆华, 等. 多功能超润湿材料的设计制备与应用[J]. 化学进展, 2018, 30(1): 87-100.ZHAN Xiao-li, JIN Bi-yu, ZHANG Qing-hua, et al. Design and Applications of Multifunctional Super-Wetting Materials[J]. Progress in Chemistry, 2018, 30(1): 87-100.

[11] CAO Liang-liang, JONES A K, SIKKA V K, et al. Anti- Icing Superhydrophobic Coatings[J]. Langmuir: the ACS Journal of Surfaces and Colloids, 2009, 25(21): 12444- 12448.

[12] VARANASI K K, HSU M, BHATE N, et al. Spatial Control in the Heterogeneous Nucleation of Water[J]. Applied Physics Letters, 2009, 95(9): 094101.

[13] ALIZADEH A, YAMADA M, LI Ri, et al. Dynamics of Ice Nucleation on Water Repellent Surfaces[J]. Langmuir, 2012, 28(6): 3180-3186.

[14] NOSONOVSKY M, HEJAZI V. Why Superhydrophobic Surfaces are not always Icephobic[J]. ACS Nano, 2012, 6(10): 8488-8491.

[15] WONG T S, KANG S H, TANG S K Y, et al. Bioinspired Self-Repairing Slippery Surfaces with Pressure-Stable Omniphobicity[J]. Nature, 2011, 477(7365): 443-447.

[16] NOSONOVSKY M. Slippery when Wetted[J]. Nature, 2011, 477(7365): 412-413.

[17] TUO Yan-jing, ZHANG Hai-feng, CHEN Wei-ping, et al. Corrosion Protection Application of Slippery Liquid- Infused Porous Surface Based on Aluminum Foil[J]. Applied Surface Science, 2017, 423: 365-374.

[18] LIU Yan, LI Xin-lin, JIN Jing-fu, et al. Anti-Icing Property of Bio-Inspired Micro-Structure Superhydrophobic Surfaces and Heat Transfer Model[J]. Applied Surface Science, 2017, 400: 498-505.

[19] 陈华伟, 张鹏飞, 张力文, 等. 猪笼草口缘区表面液体单方向连续搬运机制[J]. 中国科学基金, 2016, 30(3): 217-219. CHEN Hua-wei, ZHANG Peng-fei, ZHANG Li-wen, et al. Continuous Directional Water Transport on the Peristome Surface of Nepenthes Alata[J]. Bulletin of National Natural Science Foundation of China, 2016, 30(3): 217-219.

[20] 姜晨, 朱达, 魏久翔, 等. 基于3D打印的大尺寸猪笼草口缘区仿生表面设计[J]. 机械工程学报, 2021, 57(13): 225-231. JIANG Chen, ZHU Da, WEI Jiu-xiang, et al. Design of Large-Scale Structural Surfaces Inspired by the Peristome of Nepenthes Alata Based on 3D Printing[J]. Journal of Mechanical Engineering, 2021, 57(13): 225-231.

[21] YANG G W. Laser Ablation in Liquids: Applications in the Synthesis of Nanocrystals[J]. Progress in Materials Science, 2007, 52(4): 648-698.

[22] SHAHEEN M E, GAGNON J E, FRYER B J. Femtosecond Laser Ablation of Brass in Air and Liquid Media[J]. Journal of Applied Physics, 2013, 113(21): 213106.

[23] ZHANG Dong-shi, RANJAN B, TANAKA T, et al. Multiscale Hierarchical Micro/Nanostructures Created by Femtosecond Laser Ablation in Liquids for Polarization- Dependent Broadband Antireflection[J]. Nanomaterials, 2020, 10(8): 1573.

[24] LI Guo-qiang, LI Jia-wen, ZHANG Chen-chu, et al. Large-Area One-Step Assembly of Three-Dimensional Porous Metal Micro/Nanocages by Ethanol-Assisted Femtosecond Laser Irradiation for Enhanced Antireflection and Hydrophobicity[J]. ACS Applied materials interfaces, 2015, 7(1): 383-390.

[25] WILSON P W, LU Wei-zhe, XU Hao-jun, et al. Inhibition of Ice Nucleation by Slippery Liquid-Infused Porous Surfaces (SLIPS)[J]. Physical Chemistry Chemical Physics, 2013, 15(2): 581-585.

[26] WEI Cun-qian, JIN Bi-yu, ZHANG Qing-hua, et al. Anti-Icing Performance of Super-Wetting Surfaces from Icing-Resistance to Ice-Phobic Aspects: Robust Hydrophobic or Slippery Surfaces[J]. Journal of Alloys and Compounds, 2018, 765: 721-730.

[27] LIU Qi, YANG Ying, HUANG Meng, et al. Durability of a Lubricant-Infused Electrospray Silicon Rubber Surface as an Anti-Icing Coating[J]. Applied Surface Science, 2015, 346: 68-76.

[28] CASSIE A B D, BAXTER S. Wettability of Porous Surfaces[J]. Transactions of the Faraday Society, 1944, 40(0): 546-551.

[29] WENZEL R N. Resistance of Solid Surfaces to Wetting by Water[J]. Industrial & Engineering Chemistry, 1936, 28(8): 988-994.

[30] JUNG Y C, BHUSHAN B. Wetting Behaviour during Evaporation and Condensation of Water Microdroplets on Superhydrophobic Patterned Surfaces[J]. Journal of Microscopy, 2008, 229(1): 127-140.

[31] WIER K A, MCCARTHY T J. Condensation on Ultrahydrophobic Surfaces and Its Effect on Droplet Mobility: Ultrahydrophobic Surfaces are not always Water Repellant[J]. Langmuir, 2006, 22(6): 2433-2436.

[32] NARHE R D, BEYSENS D A. Nucleation and Growth on a Superhydrophobic Grooved Surface[J]. Physical Review Letters, 2004, 93(7): 076103.

[33] CHENG Zhong-jun, LAI Hua, ZHANG Nai-qing, et al. Magnetically Induced Reversible Transition between Cassie and Wenzel States of Superparamagnetic Microdroplets on Highly Hydrophobic Silicon Surface[J]. The Journal of Physical Chemistry C, 2012, 116(35): 18796- 18802.

[34] JOGHEE S H, UTHANDI K M, SINGH N, et al. Evolution of Temperature-Driven Interfacial Wettability and Surface Energy Properties on Hierarchically Structured Porous Superhydrophobic Pseudoboehmite Thin Films[J]. Langmuir, 2020, 36(23): 6352-6364.

[35] ZHENG Q S, YU Y, ZHAO Z H. Effects of Hydraulic Pressure on the Stability and Transition of Wetting Modes of Superhydrophobic Surfaces[J]. Langmuir: the ACS Journal of Surfaces and Colloids, 2005, 21(26): 12207- 12212.

[36] BOREYKO J B, BAKER C H, POLEY C R, et al. Wetting and Dewetting Transitions on Hierarchical Superhydrophobic Surfaces[J]. Langmuir, 2011, 27(12): 7502-7509.

[37] BOREYKO J B, COLLIER C P. Delayed Frost Growth on Jumping-Drop Superhydrophobic Surfaces[J]. ACS Nano, 2013, 7(2): 1618-1627.

[38] KULINICH S A, FARHADI S, NOSE K, et al. Superhydrophobic Surfaces: Are they Really Ice-Repellent?[J]. Langmuir, 2011, 27(1): 25-29.

[39] KIM P, WONG T S, ALVARENGA J, et al. Liquid- Infused Nanostructured Surfaces with Extreme Anti-Ice and Anti-Frost Performance[J]. ACS Nano, 2012, 6(8): 6569-6577.

Low Ice Adhesion Deicing/Anti-icing Surface of Porous Microcavity Inspired by Nepenthes

,,*,,,

(School of Manufacturing Science and Engineering, Southwest University of Science and Technology, Sichuan Mianyang 621010, China)

Ice accretion on solid surfaces is a common phenomenon in winter, which brings a lot of inconvenience to daily life and even causes serious disasters. At first, the superhydrophobic surface is considered as an ideal anti-icing surface for its micro/nano-textured structure and low surface tension. Air cushion formed between droplets and the surface leads to the decrease of contact area which contributes to delayed icing. In a high humidity environment, however, the droplets can easily intrude into the micro-nano structures, resulting in interlock. The ice is more difficult to remove. Fortunately, slippery liquid-infused surface (SLIPS) with lubricating fluids to fill micro-nanostructures inspired by nepenthes can be applied in anti-icing for its low friction force. With lubricating fluid with a high freezing point as the medium, the ice can be easily removed even in an ultra-low temperature and high humidity environment. However, lubricant losses are inevitable during the icing/deicing cycles, resulting in a great durability reduction and a significant drop of the anti-deicing performance. Therefore, how to reduce the loss of lubricating fluid and improve the durability of SLIPS has become a major challenge. To improve the anti-icing/deicing durability of slippery liquid-infused surfaces (SLIPS), the stereo porous nano-microcavity array was presented under the inspiration of the slippery liquid-infused surface of nepenthes. The stereo porous nano-microcavity array was fabricated by a femtosecond laser to irradiate the nickel foil surface immersed absolutely in ethanol. Then, C16F17H19O3Si was used to modify the surface to increase the affinity of the surface to silicone oil. Finally, 50 cSt silicone oil was used to spin-coat on the modified surface, obtaining the stereo porous nano-microcavity SLIPS. The morphologies of the stereo porous nano-microcavity structure were analyzed by scanning electron microscope (SEM) and optical microscope (OM). The anti-icing/deicing performance, ice adhesion and durability of the SLIPS were evaluated through the icing delay test, ice adhesion test and high-temperature evaporation test, respectively. Due to the capillary action of the stereo porous nano-microcavity structure, the distilled water droplets on the surface of the stereo porous nano-microcavity with lipophilicity and hydrophobicity could be pinned. It indicated that the stereo porous nano-microcavity structure could perfectly lock the lubricating fluid to improve the durability of SLIPS. Compared with the unstructured surface, the icing delay test showed that the SLIPS delayed the icing time by 2.8 times. Furthermore, the supercooled droplet was affected by condensed water in a low temperature and high humidity environment to realize the self-driving of condensed water. The SLIPS was put in a high temperature environment of 80 ℃ for ten minutes, then followed with the icing/deicing cycle experiment. After 10 cycles, the contact angle was 110°, the sliding angle was 8.5°, and ice adhesion was 3.6 kPa. The stereo porous nano-microcavity array structure is induced on the surface of nickel foil by femtosecond laser scanning nickel foil immersed in ethanol. It can reduce the loss of lubricant on the SLIPS surface and effectively improve the ice durability of SLIPS. Excellent durability and low ice adhesion make this SLIPS have the potential to be applied in various anti-icing/deicing fields.

bionics; femtosecond laser direct writing; nano-microcavity structure; SLIPS; low ice adhesion; anti-icing; deicing

2023-01-06;

2023-08-25

TG174

A

1001-3660(2023)10-0313-08

10.16490/j.cnki.issn.1001-3660.2023.10.027

2023-01-06;

2023-08-25

结冰与防除冰重点实验室开放基金(IADL20210408)

Supported by Open Fund of Key Laboratory of Icing and Anti/De-icing (IADL20210408)

向科峰, 尹欢, 宋岳干, 等.受猪笼草启发的多孔微腔低冰黏附防除冰表面[J]. 表面技术, 2023, 52(10): 313-320.

XIANG Ke-feng, YIN Huan, SONG Yue-gan, et al. Low Ice Adhesion Deicing/Anti-icing Surface of Porous Microcavity Inspired by Nepenthes [J]. Surface Technology, 2023, 52(10): 313-320.

通信作者(Corresponding author)

责任编辑:万长清