All-solid-state acousto-optic mode-locked laser operating at 660 nm

WANG Yu-ning,ZHENG Quan1,,SU Xin ,BAI Zhong-shu,ZHANG Xiu-qi,LIU Chao-zhi,LIU Wei

(1.Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, Changchun 130033, China;2.Changchun New Industries Optoelectronics Technology Co., Ltd., Changchun 130103, China)

Abstract: Red lasers with a picosecond pulse width are widely used in various fields such as industrial,medical,scientific research and information strorage due to their narrow pulse width and high peak power.This paper presents an all-solid-state laser,operating at 660 nm with picosecond pulse width,narrow band,and high conversion efficiency,which is demonstrated by the acousto-optic mode-locked (AOML) method.By optimizing the cavity and implementing external frequency doubling with two LiB3O5 (LBO) crystals along with various techniques,a mode-locked red laser source with a maximum output power of 8.6 W is developed.The laser operates in a pulsed side-pumped regime and contains the mode-locked pulses with a frequency of 100 MHz and a pulse width of 887 ps.The optical-to-optical conversion efficiency from 1 319 nm to 660 nm can reach up to 41%.

Key words: Acousto-Optic Mode-Locked (AOML);Non-Critical Phase-Matched (NCPM);macro-micro pulse

1 Introduction

In recent years,red lasers have been extensively discussed for their wide range of applications in laser medicine[1-6],laser display[7]and as a pumping source for tunable lasers,such as Cr:LiSAF[8].Due to its advantages of narrow-pulse duration and high peak power,the laser with picosecond pulse width is more applicable in these fields[9].In 2008,Zhuet al.demonstrated a 670.7 nm laser of 8.1 W via frequency doubling of an Nd:YAP laser using an LBO crystal[10].The project team demonstrated a 19.7 W 670.7 nm laser through the intracavity frequency doubling of a Q-switched,Z-cavity,Nd:YAP laser with an LBO in the following year[11].In 2019,Liet al.demonstrated a diode-end-pumped continuous wave (CW) passively mode-locked picosecond 1 319 nm Nd:YAG laser with a semiconductor saturable absorber mirror (SESAM),and the maximum average output power of the laser is up to be 10.3 W[12].In 2020,Liuet al.reported a 13 W CW intracavity frequency-doubled laser at 670.8 nm,which is produced by the second harmonic generation of a diode side-pumped Nd:YAP crystal laser with a type-II non-critical phase-matched LBO crystal[13].In 2023,Hsiehet al.reported an Nd:YVO4Raman laser with output wavelengths of 671 nm and 714 nm and output powers of 4.5 W and 1.8 W,respectively[14].

Compared with the CW,Q-switched,passive mode-locked lasers,the actively Acoustio-Optic Mode-Locked (AOML) laser exhibited significant advantages,including higher stability,higher peak power,and higher detection sensitivity.However,only a few reports to date have discussed such lasers,especially in red light resource.Our team conducted some researches on AOML using both infrared and yellow laser resources[15].In this paper,we propose an all-solid-state 660 nm mode-locked pulsed red laser based on external-cavity frequency doubling technology of side-pumped Nd:YAG laser.Through the AOML method,a number of modelocked pulsed sequence output is achieved,and the longitudinal mode spacing of mode-locked pulse contained is approximately about 10 ns.By optimizing the cavity and adopting various techniques,an acousto-optic actively mode-locked red laser source is obtained with the maximum output power of 8.6 W at the frequency of 100 MHz.The linewidth is less than 0.6 pm and the pulse width is about 887 ps.The conversion efficiency from 1 319 nm to 660 nm reaches a maximum of 41%.

2 Experiment

The schematic diagram of the actively controlled AOML 660 nm laser is shown in Fig.1.The laser system consists of two subsystems: a 1 319 nm laser subsystem and an external-cavity frequency doubling subsystem.

2.1 1 319 nm laser subsystem

The 1 319 nm laser subsystem consists of 1 319 nm acousto-optic mode-locked oscillators and 1 319 nm power amplifiers.This power scaling method uses a low average power master oscillator to produce the desired pulse waveform,and then uses an amplification stage to boost the power to the desired level.The 1 319 nm oscillator comprises two laser diode side-pumped pulsed Nd:YAG laser modules (LM1,LM2),a pair of Fabry-Perot (FP) etalons,a 90° quartz rotator (QR),an acousto-optic mode-locker,a high-reflection mirror,a KTP crystal,two mirror compensating mirrors (L1,L2),and an output coupler.One of the oscillator LD pumped modules consists of a pump source and an Nd:YAG laser crystal.The self-developed pump source consists of twelve diode bars emitting at a wavelength of 808 nm and provides a total pump peak power of 1 800 W.The laser crystal is a 0.6% Nd3+doped Nd:YAG crystal with a dimension of ϕ3×65 mm,and anti-reflection coating at 1 319 nm on both sides.The use of low doping concentration generates a uniform gain distribution in the Nd:YAG rod,resulting in an improved beam quality.To compensate the thermal effects induced by birefringence,a 90° rotator is inserted between two LD modules.Bi-concave lenses (L1,L2) are used to compensate for the thermal lens generated by the Nd:YAG crystals with the condition of high pump power density,and this method can make the cavity operating at the stability zone.The acousto-optic(AO) module is a mode-locked device which achieve mock locked frequency at 100 MHz.According to AO mode locked principle,the physical length of the cavity must match the laser modulation frequency.The cavity mode frequency is determined asf=c/2L,and the cavity length is controlled by moving the high-reflection mirrors fixed on a high-precision translation stage.The cavity mode frequency is set to 100 MHz by adjusting the cavity length to 1.5 m.By inserting a KTP crystal with an aperture size of 4 mm × 4 mm into the cavity,the high order laser mode is “cleaned” to ensure stable laser frequency locking.To achieving mode matching between the oscillators and the amplifier stage,a beam shaping device (Beam Expander 1) is inserted into the optical path.Thermal stress and thermal birefringence are effectively compensated by inserting a thermal compensation device.

The 1 319 nm amplifier stage consists of two amplifier LD modules (LM3,LM4),a beam shaping device and a thermal compensation device.One of the amplifier LD pumped modules consists of a pump source and an Nd:YAG laser crystal.The pump source is self-developed and consists of eighteen diode bars with emission wavelength at 808 nm and could provide a total pump peak power of 1 800 W.

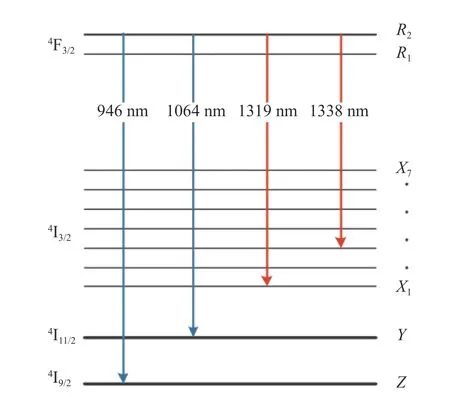

The energy level diagram of Nd3+in Nd:YAG crystals is shown in Fig.2 (color online)[16].The operation of Nd:YAG lasers at 1 319 nm is more challenging than at 1 064 nm primary due to the smaller emission cross section (0.92×10-19cm2for 1 319 vs.4.6×10-19cm2for 1 064 nm) at this wavelength.Hence,Nd:YAG laser will preferentially operate at 1 064 nm.Therefore,it must be suppressed to allow the 1 319 nm power to circulate.Meanwhile,the4F3/2-4I13/2transition in the 1.3 μm wavelength region has two intense overlapping transitions.One is the R2 -X1 transition at 1 319 nm and the other is the R2 -X3 transition at 1 338 nm.The two transition lines have close stimulated emission cross sections,which are 0.87×10-19cm2and 0.92×10-19cm2.Therefore,if there is no any filter component in the laser cavity or the differentiation of the transmission ratios at 1 319 nm and 1 338 nm of the output coupler is not clear enough,the two transition lines at 1 319 nm and 1 338 nm will inevitably oscillate simultaneously,and it is difficult for the diodepumped Nd:YAG 1.3 μm lasers to operate with a single wavelength of 1 319 nm or 1 338 nm[17-19].

Fig.2 Energy level diagram of an Nd:YAG crystal

1 319 nm laser oscillation can be achieved by using narrow-band mirrors made of multi-layer dielectric coatings that are highly reflective at 1 319 nm,and partial transmissive at 1064 nm and 1 338 nm.A pair of Fabry-Perot (FP) etalons are inserted into the cavity to narrow down the line width and tune the wavelength to 1 319 nm by angle and temperature control.The thicknesses of the etalons are 0.5 mm and 2.1 mm,and both have a reflectance of 50%.

2.2 Frequency-doubling subsystem

The frequency-doubling subsystem comprises two nonlinear crystals (LBO1,LBO2),four concave mirrors (M7-M10) and a harmonic beam filter(M11).The output beams at 1 319 nm are injected into the first LBO crystal to produce a 660 nm laser via a concave mirror are focal length of 150 mm.After the first second harmonic generation (SHG),the output beams are collimated and focused into the second LBO crystal with the concave mirrors (M8,M9).The two LBO crystals are type-I non-critical phase-matched (NCPM) with the dimensions of 4 mm×4 mm×30 mm and AR coating at 660 and 1 319 nm on both faces.The crystals are placed in ovens to control their temperatures accurately at 8.4 °C with an accuracy of 0.1 °C.The double-stage SHG beam is separated from the fundamental beams by a filter (M11).

The frequency-doubling subsystem is a simple and efficient single-pass SHG stage that converts the infrared power at the fundamental wavelength(1 319 nm) into a harmonic wavelength (660 nm).LBO has the advantage over BBO because it has a larger angular acceptance which can be used within the crystal to increase peak power.The birefringence in LBO can also be temperature tuned to obtain zero walk-off at 8.4 °C,and provid further efficiency benefits by allowing smaller spot sizes to be used within the crystal without decreasing the beam overlap region due to walk-off.The 30 mm length crystal is the longest available from high quality LBO vendors.The crystal temperature was set to 8.4 °C for non-critical phase matching without walk-off.

3 Results and discussion

The 1 319 nm output power of the mode-locked pulse laser with a maximum output energy of 42 mJ per pulse is obtained at a pulse repetitive frequency(PRE) of 500 Hz and a pulsed pump width is of approximately 160 μs.The mode-locked pulse with a PRF of 100 MHz has the pulse width of 887 ps.

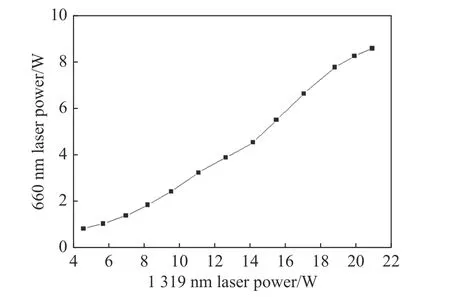

Based on the above studies,the output beams at 1 319 nm are injected into the frequency-doubling subsystem.Some optical systems were designed to achieve high conversion efficiency.Then,the beam combiner mirror was used to focus the beam on LBO crystals.When the output power of 1 319 nm was 21 W,an average power of 8.6 W output laser at 660 nm was obtained.The conversion efficiency from 1 319 nm to 660 nm is up to 41%.

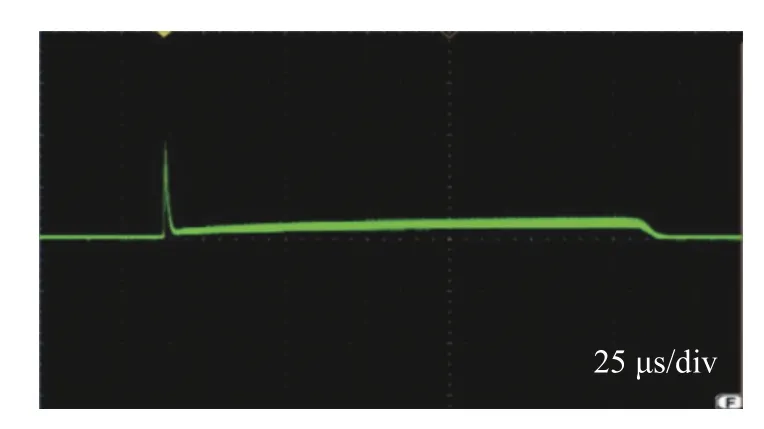

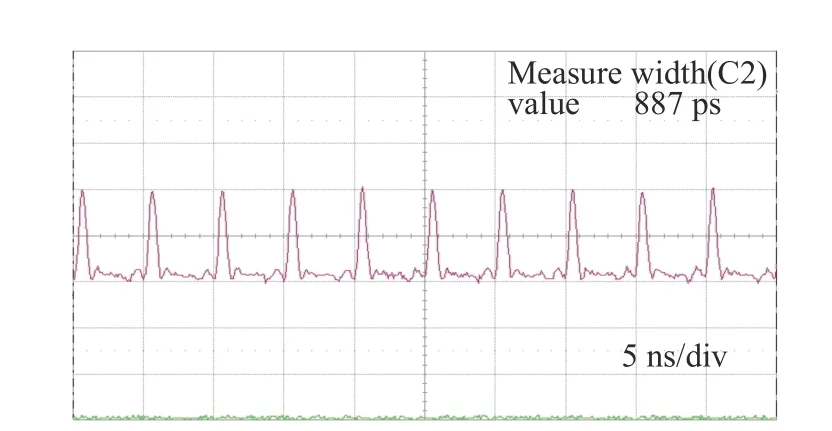

The 660 nm pulsed waveform is shown in Fig.3-Fig.4 (color online).The oscillator laser beam should be operated at TEM00beam,and the cavity length must be stable and equal to modelocked frequency.The waveform is orderly when the oscillator laser beam is TEM00beam.Main pulse internal contains a number of mode-locked pulse with the frequency of 100 MHz,and each modelocked pulse is stable amplitude.If any multi-mode is introduced,the waveform becomes unstable and no mode-locked pulse is achieved,and the 660 nm red conversion efficiency is very low.If the cavity length is not equal to the mode-locked frequency,the mode-locked waveform will be disordered,and the mode-locking cannot be achieved.Therefore,the cavity design and cavity length stability are important for the forming of mode-locked pulse.It can be proved that the waveform is a mode-locked pulse by adjusting the bandwidth of the oscilloscope.When the bandwidth is adjusted to 20 MHz,the signal of the high frequency part is filtered,and the 660 nm laser waveform is shown in Fig.3.When the bandwidth is adjusted to 350 MHz,the signal of the high frequency part can be acquired,and the laser waveform is shown in Fig.4.The pulse widths of the micro pulses are shown in Fig.5.Stable mode-locked pulse with high conversion efficiency can be achieved without damaging the optical device.By inserting a KTP crystal into the cavity,the high order laser mode is “cleaned” to ensure stable laser frequency locking.

Fig.3 The laser pulse waveform (when oscilloscope's bandwidth is adjusted to 20 MHz)

Fig.4 Schematic for macro-micro pulse waveforms

Fig.5 Micro pulse profiles of the mode-locked 660 nm laser waveforms

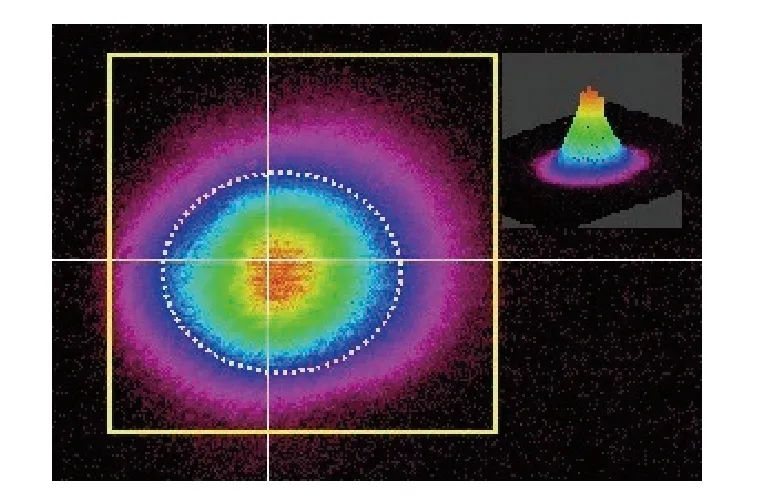

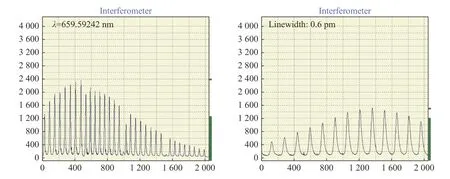

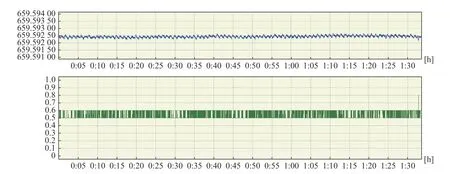

The beam shape of the 660 nm laser operating in the far-field condition is shown in Fig.6 (color online).High Finesse WS7 wavelength meter was employed to measure the spectrum and linewidth of the output laser at 660 nm,and the spectrum profile and linewidth (659.592 nm) are shown in Fig.7 and Fig.8.The 660 nm output power versus the 1 319 nm input power for frequency doubling in LBO crystals is shown in Fig.9.The stability of output power over 2 h is 0.91% shown in Fig.10.

Fig.6 Beam profile distribution of the 659.592 nm laser

Fig.7 Spectrum profile and linewidth of red laser (660nm) output pulse

Fig.8 The long-term stability of laser frequency and linewidth of red laser

Fig.9 660 nm output power versus the input power for frequency doubling in LBO crystals

Fig.10 Power stability of the output laser over 2 hours

4 Conclusion

In this paper,a high power,high conversion efficiency,and small size laser diode side-pumped 660 nm all-solid-state pulsed laser has been realized using an external frequency doubling method.By optimizing the cavity and adopting various techniques,a mode-locked red laser source is obtained with a maximum output power of 8.6 W,and the frequency of 100 MHz.The linewidth is less than 0.6 pm,and the pulse width is 887 ps.The conversion efficiency from 1 319 nm to 660 nm is up to 41%.