7075高强铝合金构件冷成形强化机制研究

陈庆洋,庞秋,胡志力,1b,刘祥

7075高强铝合金构件冷成形强化机制研究

陈庆洋1a,庞秋2*,胡志力1a,1b,刘祥3

(1.武汉理工大学 a.现代汽车零部件技术湖北省重点实验室 b.汽车零部件技术湖北省协同创新中心 武汉 430070;2.武汉东湖学院 机电工程学院,武汉 430212;3.东实(武汉)实业有限公司,武汉 430000)

针对7075高强铝合金构件在固溶-淬火-时效处理过程中成形精度低的问题,提出了7075高强铝合金预强化冷成形工艺,研究7075高强铝合金构件冷成形强化机制。基于高强铝合金短流程高性能成形技术,经过固溶-时效处理,获得预强化处理的7075铝合金板料,使用预强化处理的7075铝合金板料冷成形试制帽形梁。通过拉伸试验、杯突试验测试预强化处理的7075铝合金板料及帽形梁力学性能,并通过透射电子显微镜试验解释7075高强铝合金构件冷成形强化机制。预强化处理的7075铝合金板料抗拉强度为540 MPa,延伸率为19.3%,强度接近7075铝合金T6态强度水平,塑性接近7075铝合金O态塑性水平。杯突值为16.6 mm,达到7075铝合金O态的87%。使用预强化处理的7075铝合金板料冷成形试制的帽形梁表面质量良好,无破裂等情况。经过烤漆工艺后,帽形梁抗拉强度为(560±5)MPa,屈服强度为(480±5)MPa,与7075高强铝合金T6态强度相当。预强化处理的7075铝合金板料基体内部存在大量GP Ⅱ区组织,这有助于提高7075高强铝合金的强度和塑性。使用预强化处理的7075铝合金板料冷成形试制的帽形梁在烤漆工艺处理时,基体中部分GP Ⅱ区会转变为η'相,析出相的转变和加工硬化的结合提高了成形构件的强度,使其强度可以达到7075高强铝合金T6态强度水平。

7075铝合金;预强化成形工艺;冷成形;析出相转变;加工硬化

7075高强铝合金因其卓越的强度重量比、耐腐蚀性、热处理性能而被广泛应用于航空航天工业和汽车工业等多个领域[1-3]。7075高强铝合金构件大多应用于强度要求较高的位置,因此常常需要固溶-时效处理以提高成形构件的强度和硬度[4-5]。在7075高强铝合金冲压成形过程中常常会引入残余应力,固溶、时效等热处理工艺有助于释放残余应力,防止成形构件出现开裂等情况[6-7]。然而,对7075高强铝合金构件进行热处理不可避免地会增加工艺流程,导致生产成本增高和生产效率降低,并且热处理可能导致成形构件的尺寸变化,使成形精度降低[8-11]。

目前关于7075高强铝合金成形方法研究最多的是由帝国理工大学林建国院士提出的热成形-淬火一体化技术,该技术的应用大大提高了高强度铝合金的成形性能。但是其固溶、时效工艺处理时间较长,导致其工艺流程较长,生产效率较低[12-14]。Sonar等[15]研究发现,经过固溶-淬火处理后,7075铝合金结构部件内部存在较高的残余应力,在后续的自然时效过程中结构部件会发生严重的塑性变形。Zbigniew等[16]在研究7075铝合金W态成形B柱时发现,在回弹和减薄情况下,在B柱的底部出现了最大的减薄和应变积累。Jaskiewicz等[17]研究了7075铝合金板材在100 ℃和150 ℃成形时的U形原件,研究发现,虽然成形后的U形原件抗拉强度达到540 MPa,但是其几何形状偏差很大。霍望图等[18]研究了7000系铝合金成形工艺,研究发现,W态和O态的7000系铝合金板料相较于T6态的7×××系铝合金板料具备更优良的室温成形性。虽然W态和O态板料等软态成形可以保证室温成形性的要求,但是成形后会有回弹现象,并且其成形后的构件强度较低,往往需要后续的热处理提高强度[19]。

通过武汉理工大学华林教授团队提出的高强铝合金短流程高性能成形技术(Pre-hardening Forming,PHF)可以获得一种高性能预强化铝合金[20-21],该合金同时具备优良的塑性和强度。通过该技术温成形得到的铝合金构件无须后续热处理,强度即可达到T6态水平,能够在保证成形精度的同时,大大提高生产效率。通过该技术得到的预强化铝合金大多应用于温成形和热成形上,而在冷成形上的应用研究较少。因此,本文以7075高强铝合金为研究对象,将PHF技术应用到7075高强铝合金冷成形工艺中,研究7075高强铝合金预强化冷成形工艺,以期为铝合金冷成形工艺的优化和应用提供参考。

1 试验

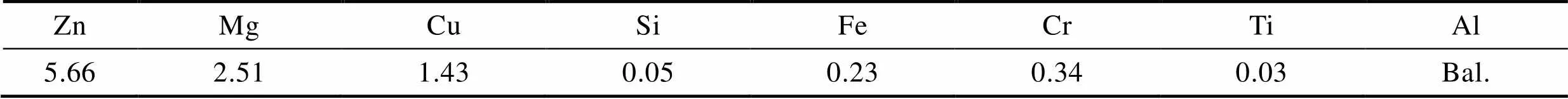

选取1.5 mm厚的7075铝合金板料为研究对象,其化学成分如表1所示。

表1 7075铝合金化学成分

Tab.1 Chemical composition of 7075 aluminum alloy wt.%

裁取合适尺寸的7075铝合金板料,经过固溶-时效处理后,获得预强化处理的7075铝合金板料,其工艺示意图如图1a所示。沿着预强化处理的7075铝合金板料轧制方向选取3个拉伸试样和3个杯突试样,拉伸试样尺寸如图1b所示。为了进行对照,分别对7075铝合金进行退火和T6态处理,以获得O态和T6态的7075铝合金板料,同样选取拉伸试样和杯突试样。拉伸试验在MMS-200型万能试验机上进行,其试验速率为0.001 s−1。杯突试验在Erichsen试验机上进行,其压边力为250 kN,试验速率为5 mm/min。拉伸试验和杯突试验结果均取平均值。

帽形梁是汽车B柱中最复杂的结构,为了验证7075铝合金预强化冷成形工艺的可行性,使用预强化处理的7075铝合金板料冷冲压试制帽形梁,冷冲压试验在DP36-250H型冲压机上进行,其凹、凸模结构如图2所示。对成形后的帽形梁进行烤漆工艺处理以模拟汽车零部件生产过程,并测试烤漆后帽形梁的结构强度。

2 结果与分析

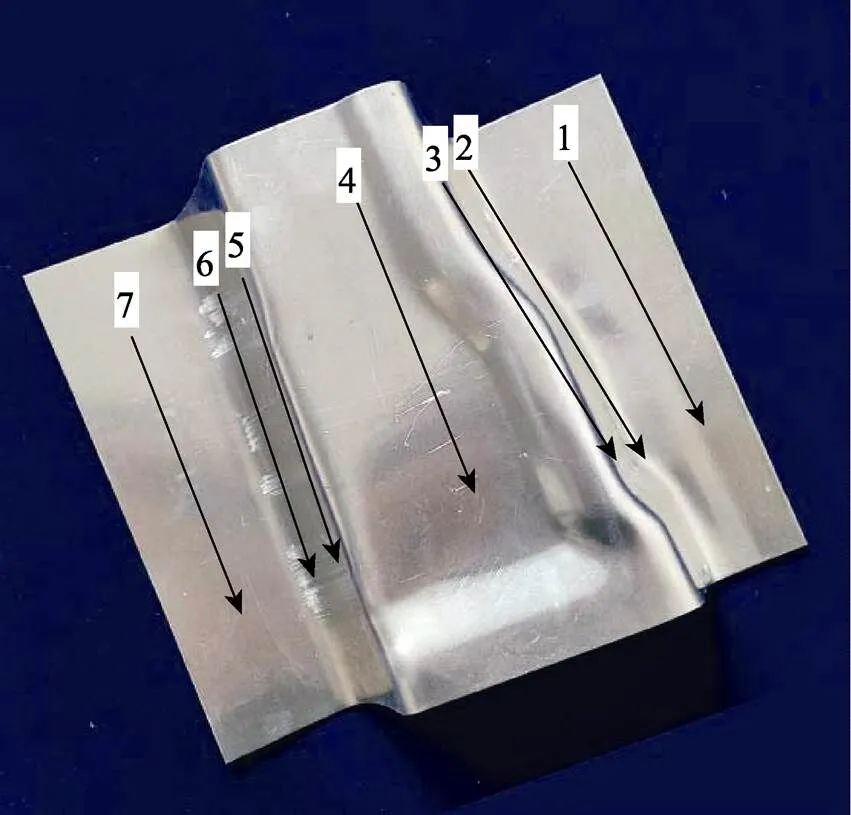

2.1 预强化处理的7075铝合金力学性能

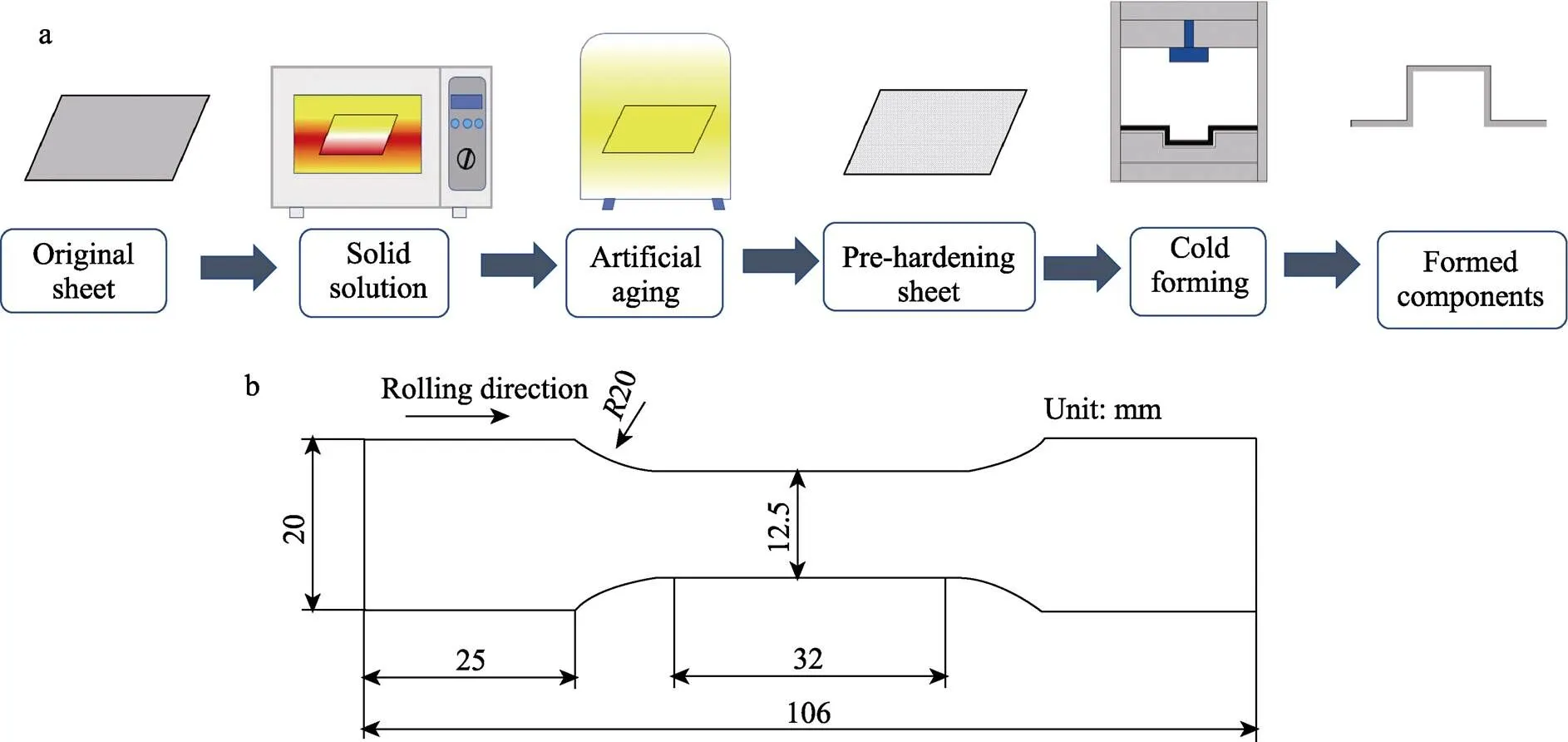

不同状态下板料的应力-应变曲线如图3a所示。预强化(Pre-hardening,PH)处理的7075铝合金板料在室温条件下具备优良的强度和塑性,其抗拉强度可达540 MPa,接近7075高强铝合金T6态强度水平,远高于7075高强铝合金O态强度。预强化处理的7075铝合金板料的延伸率可达19.3%,远高于7075高强铝合金T6态的12%,仅比O态的延伸率低2.4%。杯突试验结果如图3b所示,可知,预强化处理的7075铝合金板料杯突值相当于7075高强铝合金O态的87%,而T6态的杯突值仅为O态的53%。预强化处理的7075铝合金在保证接近7075高强铝合金T6态强度的同时,其室温成形性远高于T6态的。

图1 7075铝合金预强化冷成形工艺示意图(a)和拉伸试样(b)

图2 帽形梁冲压模具结构

图3 不同状态下板料的力学性能和成形性

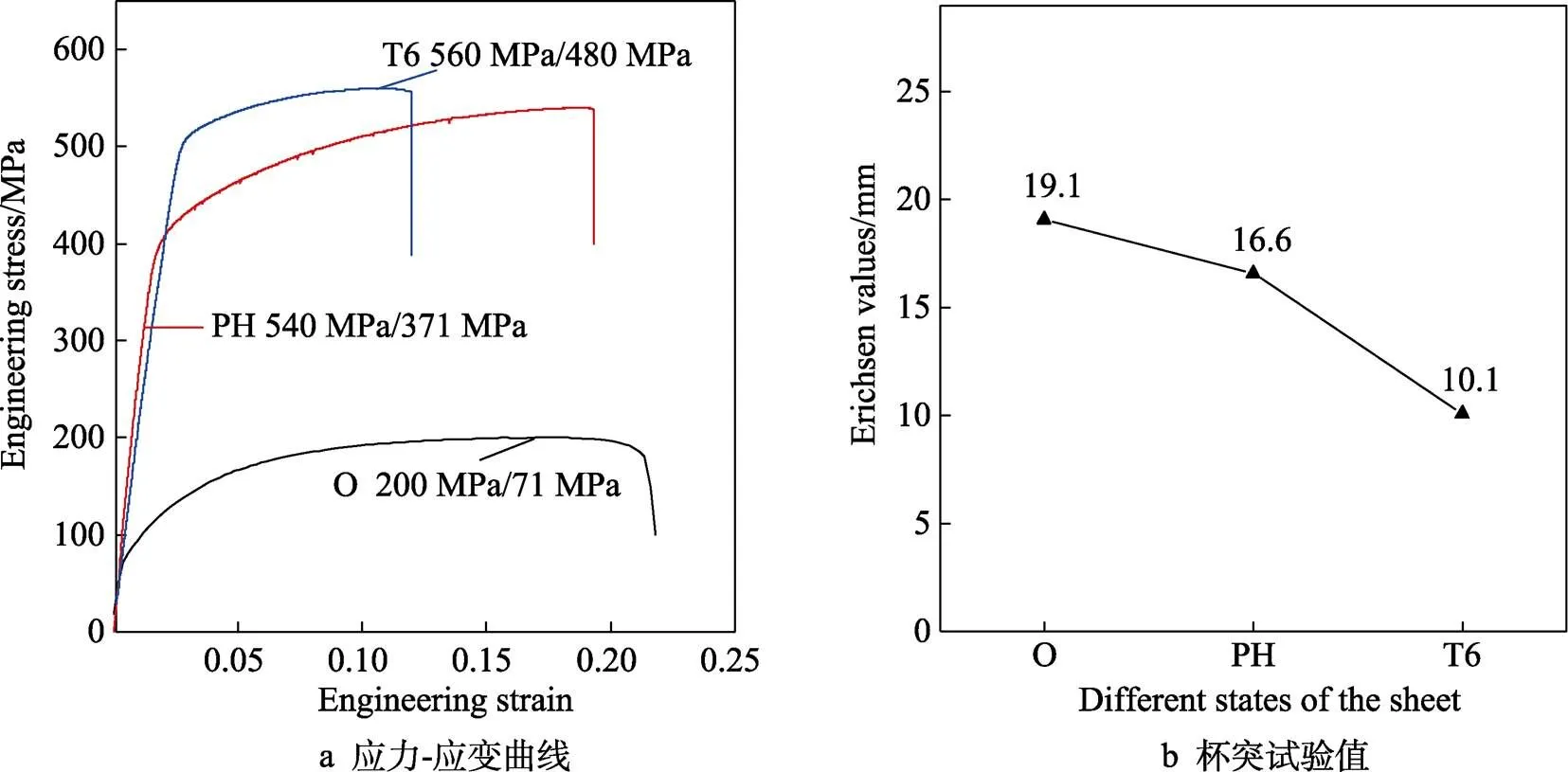

2.2 成形构件力学性能

上述试验结果表明,预强化处理的7075铝合金在室温下具备优良的强度和塑性,为了进一步验证7075铝合金预强化冷成形工艺在实际生产中的可行性,本文通过预强化处理的7075铝合金板料冷冲压试验,成功试制了汽车B柱中最复杂的部分——帽形梁,其表面质量良好,无任何裂纹等缺陷,如图4所示。

图4 帽形梁结构

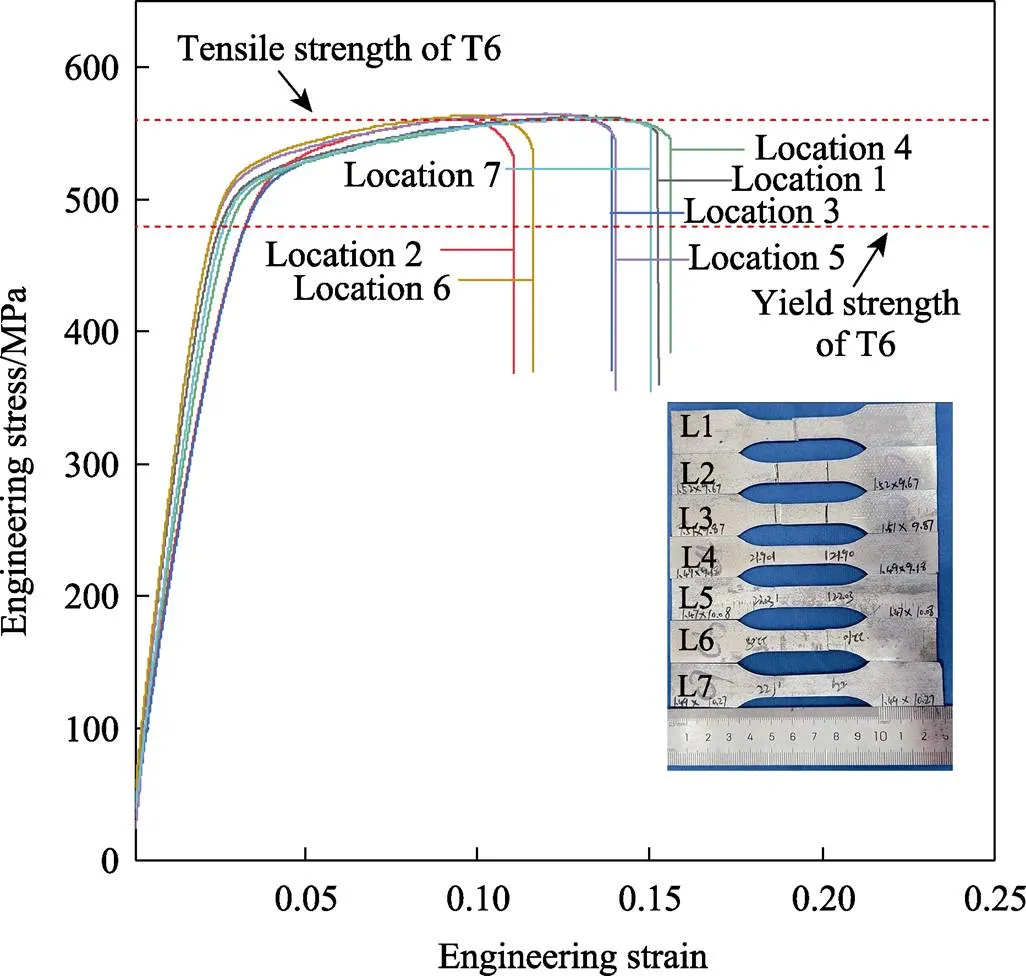

在汽车实际生产过程中,烤漆工艺有助于提高汽车部件的整体质量、耐久性等,是必不可少的一个关键步骤。为模拟实际生产过程,对冷成形的帽形梁进行烤漆工艺处理,并在帽形梁不同位置选取拉伸试样测试其结构强度。烤漆工艺处理后的帽形梁不同部位的室温拉伸结果如图5所示。

从室温拉伸结果可知,经过烤漆工艺处理的帽形梁各部位抗拉强度达到(560±5)MPa,屈服强度可达(480±5)MPa,这与7075高强铝合金T6态的强度水平相当。

图5 烤漆后帽形梁不同部位的室温拉伸曲线

2.3 7075高强铝合金冷成形强化机制

7075铝合金进行T6处理会增加η'相等强化相在基体中的析出[22],如图6a所示,析出相提高了铝合金强度,但同时析出相作为位错运动的障碍,限制了基体的塑性变形,导致T6态7075铝合金在室温下强度高,但室温成形性差。而经过预强化处理的7075铝合金内部组织主要为GP Ⅱ区,如图6b所示,GP Ⅱ区是铝合金析出相成核过程中的中间阶段。GP Ⅱ区可在一定程度上阻碍晶体的位错运动,它与位错的相互作用阻碍了塑性变形的进行,从而提高了预强化处理的7075铝合金强度。同时,由于GP Ⅱ区是析出相成核的中间阶段,它可以允许一定程度的位错运动。因此,相较于η'相等强化相对位错的阻碍作用,GP Ⅱ区的阻碍作用较小,这使得预强化处理的7075铝合金具备良好的塑性[23]。

图6 透射电镜图

成形构件烘烤后的透射电镜图如图7所示。预强化处理的7075铝合金板料内部主要强化相为GP Ⅱ区,由图7可知,经过短时烘烤的帽形梁的内部出现了强化相η′相[24-25],这说明在烘烤过程中,部分GP Ⅱ区转变为η′相,析出相的转变和加工硬化的结合使烤漆后的帽形梁具备与7075铝合金T6态相当的强度[26]。因其冷冲压成形过程中的变形量较大,帽形梁2、3、5、6位置的塑性较低。虽然这些位置因其变形量大而具备较大的位错密度,但是在短时烘烤过程中,其内部的细小析出物尺寸变大,导致其阻碍位错的能力降低,因此,这些大变形量位置的强度和小变形位置的强度相当。

图7 成形构件烘烤后的透射电镜图

3 结论

1)经过预强化处理的7075铝合金板料抗拉强度为540 MPa,延伸率为19.3%,强度接近7075高强铝合金T6态水平,延伸率接近7075高强铝合金O态水平,并且其杯突值可达7075高强铝合金O态的87%。预强化处理的7075铝合金板料内部强化相主要为GP Ⅱ区,这使其具有良好的力学性能。

2)使用预强化处理的7075铝合金板料冷成形试制的帽形梁的表面质量良好,无任何破裂情况。经过烤漆工艺处理后,帽形梁的抗拉强度达到(560±5)MPa,屈服强度达到(480±5)MPa,这与7075高强铝合金T6态强度水平相当。

3)经过烤漆处理后,帽形梁的内部部分强化相从GP Ⅱ区转变为η′相,析出相的转变和加工硬化的结合使帽形梁具备与7075高强铝合金T6态相当的强度。

[1] PAN X L, ZHOU L C, WANG C X, et al. Microstructure and Residual Stress Modulation of 7075 Aluminum Alloy for Improving Fatigue Performance by Laser Shock Peening[J]. International Journal of Machine Tools and Manufacture, 2022, 184: 103979.

[2] LIN R, LIU B, ZHANG J J, et al. Microstructure Evolution and Properties of 7075 Aluminum Alloy Recycled from Scrap Aircraft Aluminum Alloys[J]. Journal of Materials Research and Technology, 2022, 19(3): 354-367.

[3] 张丽娇. 航空航天高强铝合金材料应用及发展趋势研究[J]. 新材料产业, 2021(3): 7-11.

ZHANG L J. Study on Application and Development Trend of Aerospace High Strength Aluminum Alloy Materials[J]. Advanced Materials Industry, 2021(3): 7-11.

[4] 刘乐, 石大鹏, 孙晓军, 等. 航天用7055高强铝合金热变形行为及热加工图[J]. 特种铸造及有色合金, 2022, 42(5): 564-568.

LIU L, SHI D P, SUN X J, et al. Hot Deformation Behavior and Hot Working Diagram of 7055 High Strength Aluminum Alloy for Aerospace[J]. Special Casting & Nonferrous Alloys, 2022, 42(5): 564-568.

[5] TAŞGıN Y, ERGIN R. Investigation of the Effects of Deformation Aging Applied to AA 7075 Aluminum Alloy on Mechanical and Metallographic Properties[J]. Journal of Materials Engineering and Performance, 2022, 31(6): 4583-4603.

[6] 吴新星, 范家春, 邢阳, 等. 铝合金板温成形和热成形技术应用研究[J]. 轻合金加工技术, 2021, 49(1): 22-28.

WU X X, FAN J C, XING Y, et al. Application Research of Warm & Hot Deformation Technology for Aluminum Alloys[J]. Light Alloy Fabrication Technology, 2021, 49(1): 22-28.

[7] JASKIEWICZ K, SKWARSKI M, POLAK S, et al. Analysis of the Forming Process of Energy-Absorbing Elements Made from 7000 Series High-Strength Aluminum Alloy[J]. Archives of Metallurgy and Materials, 2020, 65(2): 697-705.

[8] NASIM W, KULKARNI S S, SOULAMI A, et al. Room Temperature Stamping of High-Strength Aluminum for Lightweight Structural Automotive Components[J]. Journal of Materials Engineering and Performance, 2023(11).

[9] WANKHEDE P, KURRA S, SWADESH, et al. Heat Treatment and Temperature Effects on Formability of AA2014-T6 in Incremental Forming[J]. Materials and Manufacturing Processes, 2022, 37(12): 384-392.

[10] UCKOW T, OECAL E B, GROCHE P. A Comparative Study on the Production of a Hat Profile by Roll Forming and Stamping[J]. Advanced Engineering Materials, 2023, 25(15)

[11] ZHOU J, YANG X M, WANG B Y, et al. Springback Prediction of 7075 Aluminum Alloy V-Shaped Parts in Cold and Hot Stamping[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(1): 203-216.

[12] ZHENG K L, DONG Y C, ZHENG D Q, et al. An Experimental Investigation on the Deformation and Post-Formed Strength of Heat-Treatable Aluminium Alloys Using Different Elevated Temperature Forming Processes[J]. Journal of Materials Processing Technology, 2019, 268: 87-96.

[13] 王义林, 刘勇, 耿会程, 等. 高强铝合金热冲压成形技术研究进展[J]. 航空制造技术, 2019, 62(16): 22-35.

WANG Y L, LIU Y, GENG H C, et al. Research Progresses of Hot Stamping Technology for High Strength Aluminum Alloy Sheet[J]. Aeronautical Manufacturing Technology, 2019, 62(16): 22-35.

[14] DU Z H, DENG Z S, CUI X H, et al. Deformation Behavior and Properties of 7075 Aluminum Alloy under Electromagnetic Hot Forming[J]. Materials, 2021, 14(17): 4954.

[15] SONAR T, BALASUBRAMANIAN V, MALARVIZHI S. Mitigation of Heat Treatment Distortion of AA7075 Aluminum Alloy by Deep Cryogenic Processing Using the Navy C-Ring Test[J]. Materials Testing, 2021, 63(8): 758-763.

[16] ZBIGNIEW G, KAROL J, PAWEŁ K, et al. W-Temper Forming of B-Pillar from 7075 Aluminum Alloy[J]. CIRP Annals-Manufacturing Technology, 2022, 71(1): 221-224.

[17] JASKIEWICZ K, SKWARSKI M, KACZYŃSKI P, et al. Warm Sheet Metal Forming of Energy-Absorbing Elements Made 7075 Aluminum Alloy in the Hardened State T6[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(5): 3157-3179.

[18] 霍望图, 孙涛涛, 雷诚心, 等. 高强7000(Al-Zn-Mg-Cu)系铝合金成形性研究进展[J]. 中国材料进展, 2020, 39(12): 924-933.

HUO W T, SUN T T, LEI C X, et al. Research Progress on Formability of High-Strength 7000 (Al-Zn-Mg-Cu) Series Aluminum Alloy[J]. Materials China, 2020, 39(12): 924-933.

[19] GUENZEL J, HAUSS J, GROCHE P. Opportunities, Challenges, and Influencing Factors in the Forming of Preconditioned Semi-Finished Products Made of EN AW-6082 and-7075[J]. Advanced Engineering Materials, 2023, 25(15).

[20] HUA L, ZHANG W P, MA H J, et al. Investigation of Formability, Microstructures and Post-Forming Mechanical Properties of Heat-Treatable Aluminum Alloys Subjected to Pre-Aged Hardening Warm Forming[J]. International Journal of Machine Tools and Manufacture, 2021, 169(18): 103799.

[21] WEI P F, HU Z L, PANG Q. Microstructure Evolution and Strengthening Mechanisms of High Strength Al-Zn-Mg-Cu Alloy via Pre-Hardening Forming[J]. Journal of Alloys and Compounds, 2023, 968: 172057.

[22] HUO W T, HOU L G, ZHANG Y. Warm Formability and Post-Forming Microstructure/Property of High-Strength AA7075-T6 Al Alloy[J]. Materials Science and Engineering A, 2016, 675: 44-54.

[23] KHALFALLAH A, RAHO A A, AMZERT S, et al. Precipitation Kinetics of GP Zones, Metastable η′ Phase and Equilibrium η Phase in Al-5.46wt.%Zn-1.67wt.%Mg Alloy[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(2): 233-241.

[24] 王春华, 张涛, 尹红霞, 等. 时效处理对7075铝合金组织与性能的影响[J]. 金属热处理, 2017, 42(9): 87-90.

WANG C H, ZHANG T, YIN H X, et al. Effect of Aging Treatment on Microstructure and Properties of 7075 Aluminum Alloy[J]. Heat Treatment of Metals, 2017, 42(9): 87-90.

[25] GUO Y, ZHANG J H, ZHAO H W. Microstructure Evolution and Mechanical Responses of Al-Zn-Mg-Cu Alloys during Hot Deformation Process[J]. Journal of Materials Science, 2021, 56(24): 13429-13478.

[26] ZHANG W P, LI H H, HU Z L, et al. Investigation on the Deformation Behavior and Post-Formed Microstructure/Properties of AA7075-T6 Alloy under Pre-Hardened Hot Forming Process[J]. Materials Science and Engineering A, 2020, 792: 139749.

Cold Forming Strengthening Mechanism of 7075 High-strength Aluminum Alloy Components

CHEN Qingyang1a, PANG Qiu2*, HU Zhili1a,1b, LIU Xiang3

(1.a. Hubei Key Laboratory of Advanced Technology of Automobile Components, b. Hubei Collaborative Innovation Center for Automotive Components Technology, Wuhan University of Technology, Wuhan 430070, China; 2. School of Mechanical and Electrical Engineering, Wuhan Donghu University, Wuhan 430212, China; 3. Dongshi (Wuhan) Auto Parts Co., Ltd., Wuhan 430000, China)

High-strength aluminum alloy components, such as those made of 7075 alloy, typically undergo solution treatment, quenching, and aging to enhance their strength and other properties. In response to the challenge of reduced forming precision during the heat treatment process for 7075 high-strength aluminum alloy components, a pre-strengthening cold forming process for 7075 high-strength aluminum alloy is proposed. The work aims to study the strengthening mechanisms involved in the cold forming of 7075 high-strength aluminum alloy components. By pre-hardening forming technique for high-strength aluminum alloys, the pre-hardened 7075 aluminum alloy sheets were obtained after solution treatment and aging. A cap-shaped beam was fabricated by the pre-hardening cold forming process for 7075 high-strength aluminum alloy. Mechanical properties of the pre-hardened 7075 aluminum alloy sheets and the cap-shaped beam were evaluated through tensile tests and cupping tests. Additionally, the strengthening mechanisms involved in the cold forming of 7075 high-strength aluminum alloy components were elucidated based on the results from transmission electron microscopy experiments. The pre-hardened 7075 aluminum alloy sheet exhibited a tensile strength of 540 MPa and an elongation percentage of 19.3%, with strength levels close to those of 7075 aluminum alloy in the T6 temper, and plasticity comparable to that of 7075 aluminum alloy in the O temper. The cupping value was measured at 16.6 mm, reaching 87% of the cupping value for 7075 aluminum alloy in the O temper. The cap-shaped beam produced by the pre-hardening cold forming process for 7075 aluminum alloy showed excellent surface quality, with no signs of fractures. After the painting process, the cap-shaped beam demonstrated a tensile strength of (560±5) MPa and a yield strength of (480±5) MPa, comparable to the strength of 7075 high-strength aluminum alloy in the T6 temper. The pre-hardened 7075 aluminum alloy sheet contains a significant amount of GP Ⅱ zone structure within the matrix. This structure contributes to enhancing the strength and plasticity of 7075 high-strength aluminum alloy. The cap-shaped beam fabricated by the pre-hardening cold forming process for 7075 high-strength aluminum alloy exhibits a transformation of some GP Ⅱ zones within the matrix into η' phase when treated in painting process. The combination of phase precipitation transformation and work hardening elevates the strength of the formed component, allowing it to achieve strength levels equivalent to 7075 high-strength aluminum alloy in the T6 temper.

7075 aluminum alloy; pre-hardening forming process; cold forming; phase precipitation transformation; work hardening

10.3969/j.issn.1674-6457.2024.03.016

TG166.3

A

1674-6457(2024)03-0152-07

2024-01-07

2024-01-07

国家自然科学基金(52075400,52275368);湖北省重点研发计划(2021BAA200);湖北省科技重大专项(2022AAA 001);湖北省自然科学基金(2023AFA069)

The National Natural Science Foundation of China (52075400, 52275368); The Key Research and Development Program of Hubei Province (2021BAA200); Major Program of Hubei Province (2022AAA001); Hubei Provincial Natural Science Foundation of China (2023AFA069)

陈庆洋, 庞秋, 胡志力, 等. 7075高强铝合金构件冷成形强化机制研究[J]. 精密成形工程, 2024, 16(3): 152-158.

CHEN Qingyang, PANG Qiu, HU Zhili, et al. Cold Forming Strengthening Mechanism of 7075 High-strength Aluminum Alloy Components[J]. Journal of Netshape Forming Engineering, 2024, 16(3): 152-158.

(Corresponding author)