Effect of W6+ Modification on Electrical Properties of Bi4Ti3O12 High Temperature Piezoelectric Ceramics

(School of Materials Science and Engineering, Jingdezhen Ceramic Institute; China National Light Industry Key Laboratory of Functional Ceramic Materials; Energy Storage and Conversion Ceramic Materials Engineering Laboratory of Jiangxi Province, Jingdezhen 333403, Jiangxi, China)

Abstract: WO3 modified bismuth layer-structured Bi4Ti3O12(Bi4Ti3-xWxO12, 0.00≤x≤0.16, BITW) ferroelectric ceramics were synthesized by using asolid-state reaction method. The effect of W6+ modification on microstructure and electrical properties of the Bi4Ti3O12(BIT) ceramics was studied. It was found that the grains of the BITW ceramics were refined and the microstructure was homogenized at the optimal doping concentration of W6+. As a consequence, both the conductivity and dielectric loss of the ceramics were reduced, while the piezoelectric and electromechanical properties were enhanced, due to the improved densification behavior of the materials. When the WO3 doping concentration was x=0.14, the ceramics exhibited optimum electrical properties, with d33=16 pC/N, kp=8.1%, Qm=1942, εr=160(at 100 kHz), tanδ=0.016(at 100 kHz), TC=632 ℃ and ρ=9.4×107 Ω·cm at 500 ℃, indicating that the BITW ceramics could have potential in high temperature applications.

Key words: bismuth piezoelectric ceramics; Bi4Ti3O12; piezoelectric properties; dielectric properties; thermal stability

1 Introduction

Bismuth layer-structured compounds consist of(Bi2O2)2+and perovskite-like (Am-1BmO3m+1)2-layers compiled in an alternative manner alongc-axis, leading to a chemical formula of(Bi2O2)2+(Am-1BmO3m+1)2-, where A is occupied by cations with dodecahedral coordination or complex cations through the combination of Na+, K+, Ba2+,Sr2+, Bi3+, and so on, while B is occupied by cations with hexahedral coordination or complex cations of Co3+, Fe3+, Zr4+, Ti4+, Nb5+, W6+, and so on.Meanwhile,mis a value of 1-5, which is the number of the perovskite-like layer between two (Bi2O2)2+layers[1-10]. Bismuth layer-structured ferroelectrics(BLSFs) have attracted much attention, due to the high fatigue resistance, high Curie temperatures,high coercive fields, high electromechanical figure of merit and low ageing rate. Currently, various BLSFs have been reported in the open literatures,such as CaBi2Nb2O9, Bi4Ti3O12, CaBi4Ti4O15,Na0.5Bi4.5Ti4O15, K0.5Bi4.5Ti4O15and SrBi4Ti4O15[9-19].

Bi4Ti3O12(BIT,m=3) is a typical BLSF material,with a high Curie temperature ofTC~675 ℃[1,7]. It is composed of (Bi2Ti3O10)2-and (Bi2O2)2+layers with an alternative configuration. Due to its isotropic structure, the spontaneous polarization is only present on thea-bplane. However, owing to thea-bplane conductivity is higher than that in thec-axis direction by about one order of magnitude, the BIT ceramics cannot be easily poled when they have a relatively low density. As a result, it is still a challenge to fabricate BIT ceramics with desired piezoelectric properties, thus limiting their practical applications[3-7].

During past years, various doping methods have been adopted to modify the properties of BIT ceramics. For example, Zheng et al. used Nb2O5to increase the density, reduce the conductivity and enhance the dielectric properties of BIT ceramics[7].Peng et al. reported a W/Nbco-doping approach to substitute Ti at B site, which could reduce the concentration of oxygen vacancy, thus leading to enhanced dielectric and piezoelectric performances[3]. However, the effect of doping with W6+has not been well clarified. In this regard, the current work was aimed to have a systematic study on the influence of W6+doping on phase evolution,microstructure characterization, dielectric properties,ferroelectric behaviors, high-temperature resistivity and thermal stability of BIT ceramics by using the conventional solid-state reaction method.

2 Experimental

Bi4Ti3-xWxO12(0.00≤x≤0.16) ceramics were prepared by using the conventional solid-state reaction method, with commercial powders of Bi2O3(99%), TiO2(98%) and WO3(99%) as the starting materials. The powders with designed compositions were mixed by using ball milling in ethanol with ZrO2balls for 12 h. The mixtures were calcined at 800 ℃ for 3 h, followed by ball milling for 24 h. The milled samples were dried and sieved through 60 mesh-screen. The dried powders were granulated with PVA solution (4wt.%) and compacted into pellets with a diameter of about 12 mm and thickness of about 0.6 mm at pressures of 10-12 MPa. The pellet samples were then treated with cold isostatic pressing at a pressure of 250 MPa. Finally, the green bodies were heated at 650 ℃ for 140 min to remove the PVA and sintered at 1100 ℃ for 3 h. The sintered samples were polished, coated with silver paste and fired to electrode, poled at 160 ℃ in silicone oil at electric fields of 12-15 kV/mm for 20 min. Electrical properties of the samples were measured after the poling process was finished.

Phase structure of the samples were analyzed by using X-ray diffraction (XRD, D8-Advance, Bruker,Germany), while their microstructures were observed by using scanning electron microscopy(SEM, JSM-6700F, JEOL, Japan). Piezoelectric constant (d33) was measured by using ad33-meter(ZJ-2,Institute of Acoustics, Academia Sinica).Dielectric properties as a function of temperatures were recorded at 100 kHz by using a precision impedance analyzer (TH282S). Planar electromechanical coupling factor (kp) and electromechanical quality factor (Qm) were obtained by using Agilent 4294A impedance analyzer according to the resonance-antiresonance characteristics. Ferroelectric properties of the samples were characterized by using a ferroelectric-tester (Precision Workstation).

3 Results and Discussion

3.1 Phase composition and microstructure

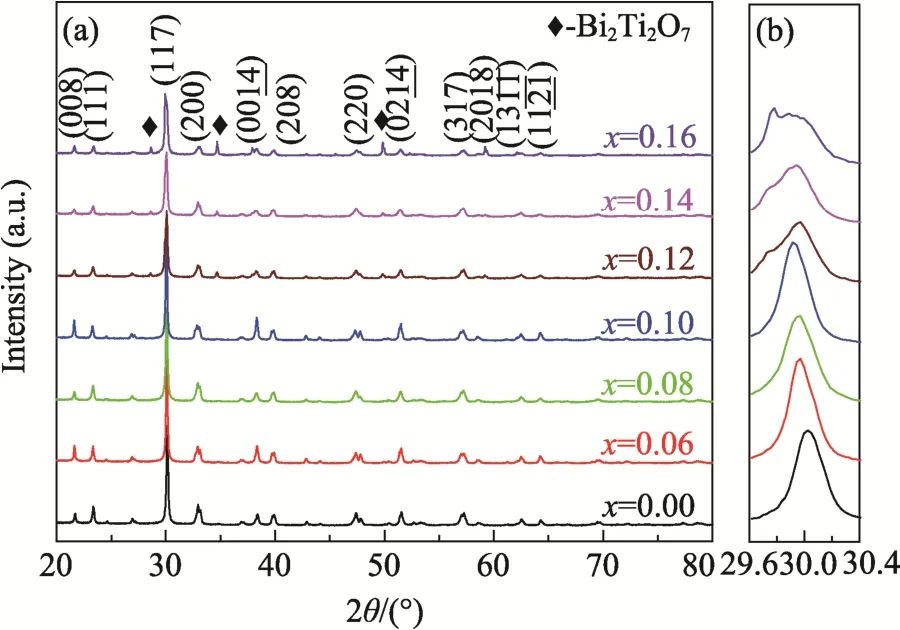

Fig.1 (a) shows XRD patterns of BITW ceramics doped with different concentrations of W6+,while zoom-in view of the patterns over 29.6-30.4 °are depicted in Fig. 1 (b). As observed in Fig.1 (a),the samples withx= 0-0.12 are of rhombohedral structure, with (117) to be the strongest peak,consistent with the characteristic of BLSFs(112m+1), while no secondary phase is present.However, in the samples withx≥ 0.12, a secondary phase is detected with a peak at about 30 °,corresponding to Bi2Ti2O7(444). This is because the substituted Ti4+ions at the B-site drafted away from the lattice site, which reacted with Bi2O3to form Bi2Ti2O7, once the concentration is sufficiently high.The presence of secondary phases inevitably has negative effect on dielectric, piezoelectric and electromechanical properties of the BITW ceramics.At the same time, the diffraction peaks shift slightly to lower angle, as illustrated in Fig. 1 (b), indicating that the unit cell is expanded, simply because the ionic radius r(W6+) = 62 pm > r(Ti4+) = 60.5 pm,according to the Bragg equation (2dsinθ = nλ).

Fig.1 XRD patterns of the BITW ceramic samples with different doping concentrations (a) wide angle and (b)zoom-in view

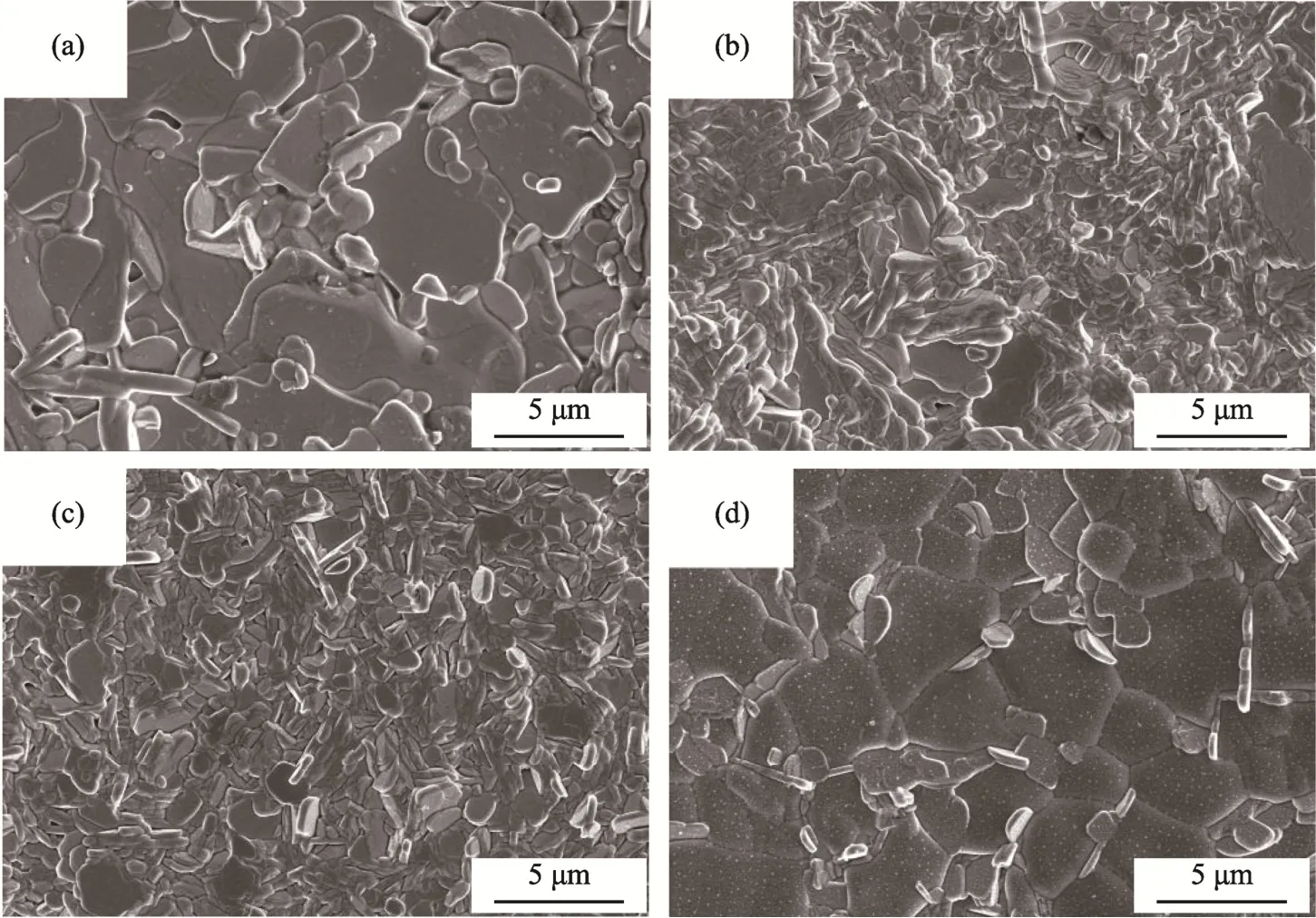

Fig.2 shows SEM images of the BITW ceramics(x= 0.00, 0.08, 0.14, 0.16) after polishing and thermally etching. It is found that the samples have been nearly fully densified, with strong adhesion among the grains. The microstructures are characterized by randomly distributed plate-like grains, because the grain growth rate in thec-axis direction is lower than that along thea-bplane, thus leading to planar grains[6,9]. After introducing a small quantity of W6+(x=0.08), the grain size of the ceramics is slightly decreased, as seen in Fig.2 (b).Also, the doping with W6+resulted in a refinement in the grains and microstructure. However, further increase in the concentration of W6+led to excess grain growth. In this case,x=0.14 is the optimal doping concentration for the BIT ceramics, with most homogeneous microstructure, lowest porosity and highest density, as demonstrated in Fig.2 (c). As expected, this sample exhibits the highest piezoelectric performances.

3.2 Dielectric properties

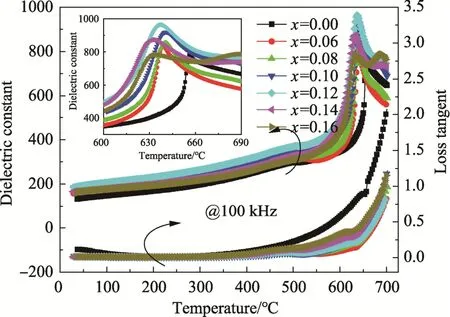

Fig.3 depicts dielectric constant and loss tangent of the BITW ceramics at 100 kHz, as a function of temperature. As revealed in Fig.3, for the samples withx≤ 0.12, dielectric constant at both room temperature and Curie temperature is increased with increasing doping concentration of W6+. This is because the substitution of Ti4+with W6+led to the formation of bismuth vacancydue to the requirement of electric neutrality. As a result, the crystal lattice is distorted and the domain wall motion is enhanced, thus leading to increase in dielectric constant[7]. Meanwhile, the Curie temperature is reduced as shown in the inset of Fig.3,since the 5d electron of W6+has higher energy than the 3d electron of Ti4+. Also, owing to r(W6+)=62 pm>r(Ti4+)=60.5 pm, the unit cell is expanded and the W6+occupied more space, so that the octahedron is squeezed[3,24]. In addition, the volatilization of Bi2O3during the high temperature sintering process would also reduce the Curie temperature[25]. For pure BIT ceramics, tanδstarts to rise at about 250 ℃ and rapidly increases as the temperature approachesTCdue to the leakage current at high temperatures, as observed in Fig.3. With the introduction of WO3, the tanδnearTCis largely reduced, suggesting the effect of WO3doping in decreasing the dielectric loss and improving dielectric properties of the BITW ceramics.

Fig.2 Surface SEM images of the polished and thermally etched BITW ceramics(a) x = 0.00, (b) x = 0.08, (c) x = 0.14 and (d) x = 0.16

Fig.3 Dielectric constant (εr) and loss tangent (tanδ) of the BITW ceramics as a function of temperature

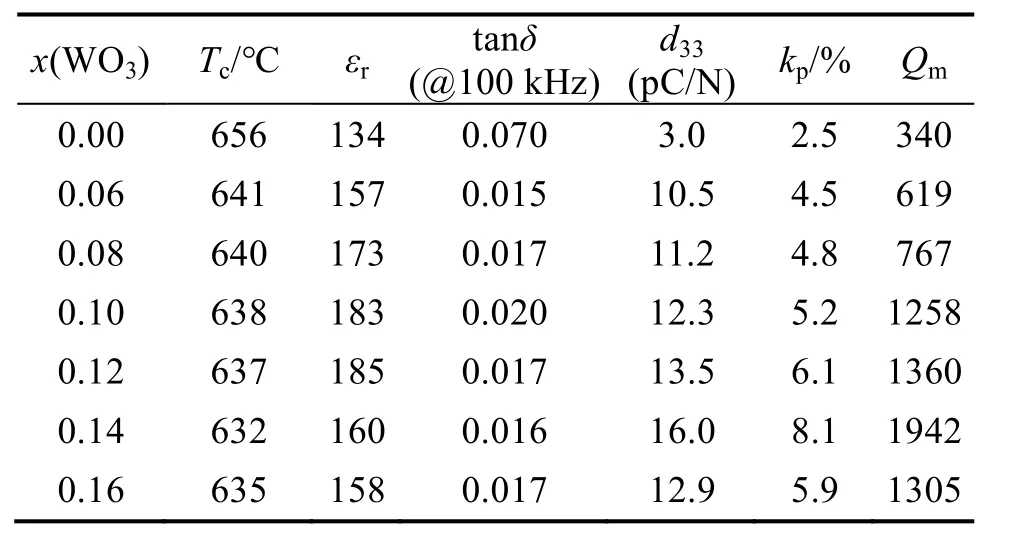

Room temperature electrical properties of the BITW ceramics are listed in Tab.1. With increasing doping concentration (x), both thed33andkpare maximized atx= 0.14, with values of 16 pC/N and 8.1%, respectively. As compared with that of the pure BIT, the piezoelectric constant is increased by about 5 times, while the value of tanδ (at 100 kHz) is 0.016, which is nearly the lowest among all the samples, further demonstrating the positive effect of W6+doping.

Tab. 1 Electrical properties of the BITW ceramics

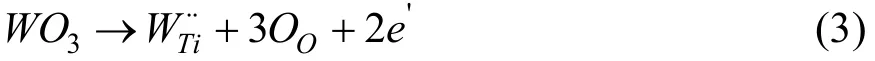

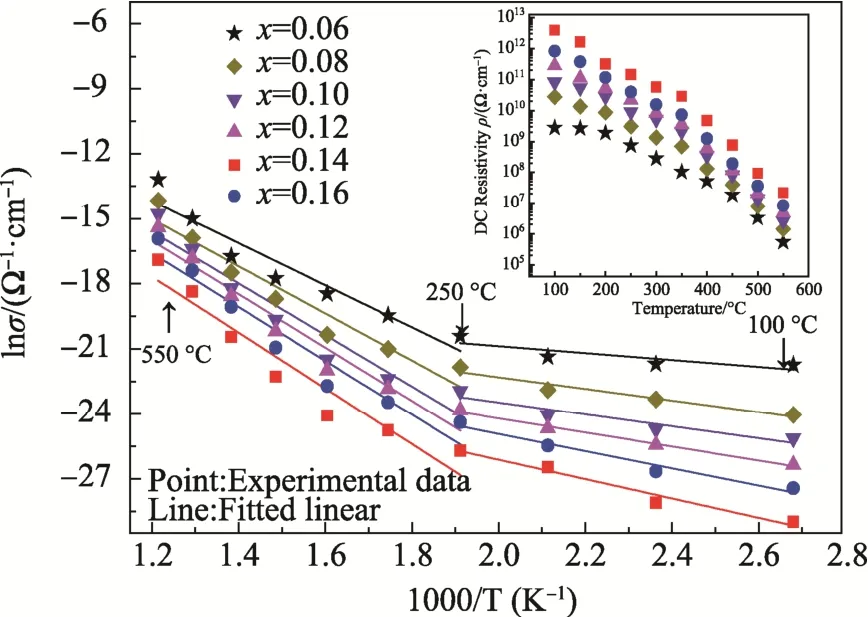

3.3 DC resistivity

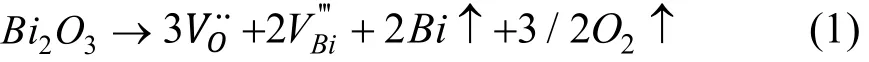

DC conductivities of the BITW ceramics versus 1/T are shown in Fig.4. DC resistivities of the samples as a function of temperature are plotted as the inset in the figure. The substitution for the B-site Ti4+with W6+could increase the resistivity of the BITW ceramics, because BIT hasp-type conduction characteristics[16]. Due to the volatilization of Bi2O3during the sintering process, both oxygen vacancyand bismuth vacancywould be produced,through the following equation:

During the cooling process, oxygen is dissolved and incorporated into the crystal lattice, creating holes, as given by:

On the other hand, when Ti4+ions at the B-site are substituted with W6+ions, the defectis formed, while releasing electrons:

The electrons would neutralize the holes, thus suppressing the concentration of the carriers[7,15].According to conductivity equation (σ=nqμ), the W-doping reduces the conductivity and increases the resistivity of the materials. At 550 ℃, the resistivity of the BITW ceramics is maximized atx= 0.14,which is 9.4×107Ω·cm, thus demonstrating potential applications in high temperature piezoelectric devices.

Fig.4 Temperature dependence of conductivity of the BITW ceramics, with the inset showing the temperature dependence of DC resistivity

3.4 Ferroelectric properties

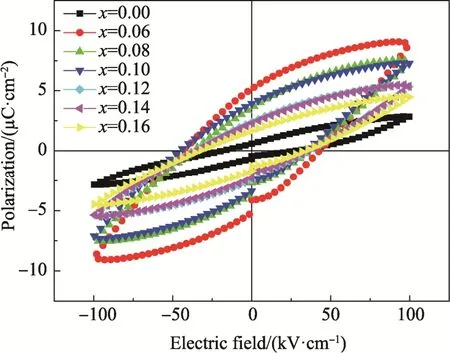

Fig.5 shows P-E hysteresis loops of the BITW ceramics measured at room temperature. All the curves are not closed, reflecting the presence of internal field related to the crystal defects and domain motion[1,25,26]. With varying concentration of W6+, spontaneous polarization (Ps) rises first and then declines, while both the remnant polarization and coercive field are increased. SEM results indicated that grain size of the BITW ceramics was reduced after the introduction of W6+, which results in an increase in coercive field, even though the content of oxygen vacancy is decreased. It is widely accepted that the coercive field is inversely proportion to the grain size, because domain motion is more difficult when there are more grain boundaries[7,29]. In addition, both the charge and radius of W6+ion is larger than those of Ti4+ion,the dipole-dipole distance is increased and the WO6octahedron is distorted, thus leading to enhancedPr.Therefore, W-doping significantly improved the ferroelectric properties of the BITW ceramics.

Fig.5 P-E hysteresis loops of the BITW ceramics

3.5 Thermal stability

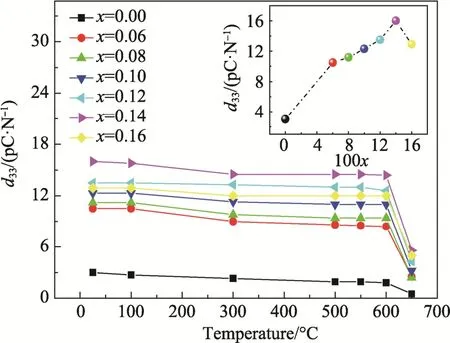

Fig.6 shows variations ofd33as a function of annealing temperature, in which the inset depicts the value ofd33versus doping concentration (x). For pure BIT ceramics, the value ofd33is very slightly decreasing with increasing temperature and suddenly drops near the Curie temperature. This is because the presence of the oxygen vacancies facilitated the reorientation of the dipoles, so that the anti-fatigue capability is weakened[7,26,27]. After doping with W6+,the concentration of the oxygen vacancy is reduced,thermal stability of the materials is enhanced. As a result, the W-doped BIT ceramics still have relatively high remnant polarization near the Curie temperature. The sample withx=0.14 has ad33level of 16 pC/N at room temperature, while the value ofd33is 14.4 pC/N at 600 ℃, corresponding to about 90% retention. Therefore, W6+-doping could improve the thermal stability of BIT ceramics.

Fig.6 d33 of the BITW ceramics versus annealing temperature,with the inset showing content x dependence of d33

4 Conclusions

(1) XRD results indicated that orthorhombic phase was observed as the content of WO3wasx≤0.10, while the samples withx≥0.12 contained secondary phase Bi2Ti2O7. Meanwhile, the diffraction peaks shifted to low-angle side,suggesting the distortion of the crystal lattice, which is beneficial to the enhancement of piezoelectric properties of the BITW ceramics.

(2) SEM observation revealed that the grain growth of the BITW ceramics was effectively retarded due to the doping with WO3as its concentration was appropriate. Due to the reduction in grain size and the increase in density, the BITW ceramics had fewer defects and thus enhanced electrical properties. Specifically, the sample withx=0.14 exhibited optimal electrical performances,withd33= 16 pC/N, tanδ= 0.016(at 100 kHz),kp8.1%, andQm= 1942.

(3) Resistivity of the BITW ceramics was also maximized in the sample withx=0.14, which was 9.4×107Ω·cm at 500 ℃, thus expanding their applications in high-temperature devices.